×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Control Arm

Suspension Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

347 Control Arms found

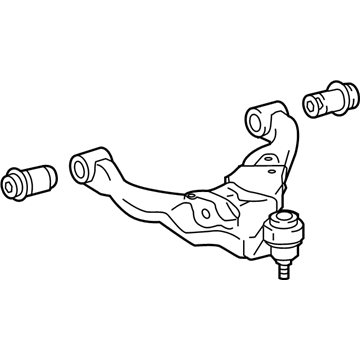

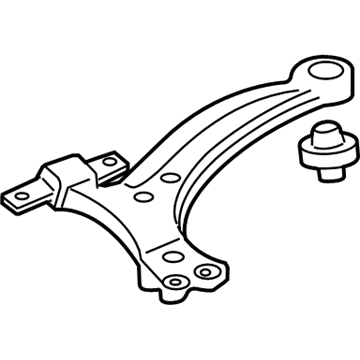

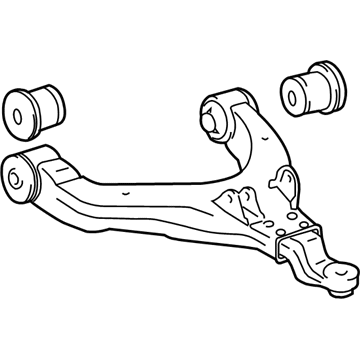

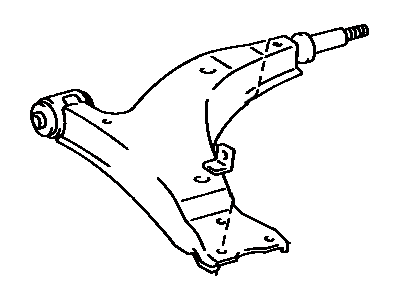

Toyota Lower Control Arm, Passenger Side

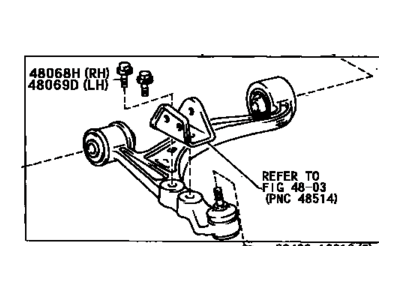

Part Number: 48068-04060$278.07 MSRP: $397.03You Save: $118.96 (30%)Product Specifications- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm, Front Right Lower; Control Arm Assembly; Arm Sub-Assembly, Front Suspension, Lower Passenger Side; Control Arm

- Position: Passenger Side

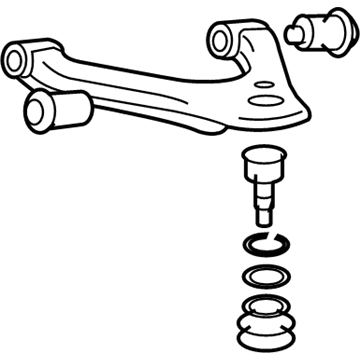

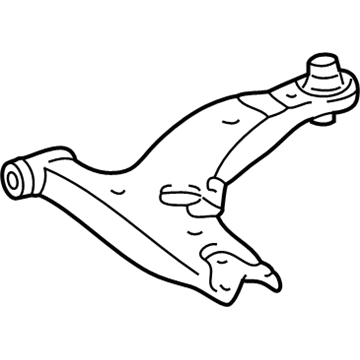

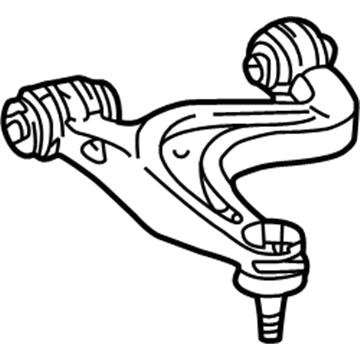

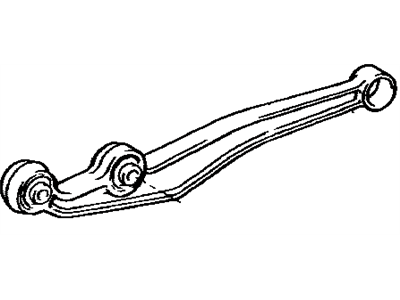

Toyota Upper Control Arm, Driver Side

Part Number: 48630-04010$282.97 MSRP: $404.01You Save: $121.04 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Assembly, Suspension; Suspension Control Arm, Front Left Upper; Control Arm Assembly; Arm Assembly, Front Suspension, Upper Driver Side; Control Arm

- Position: Upper Driver Side

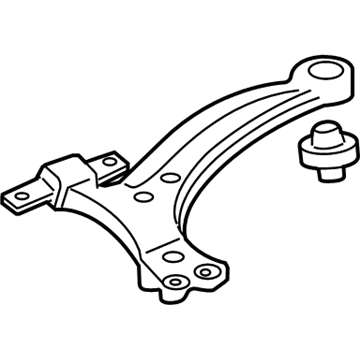

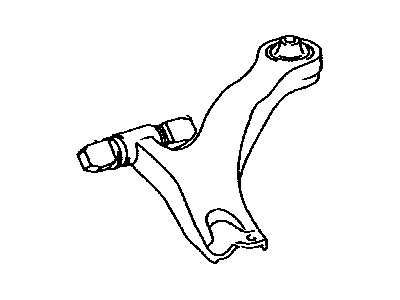

Toyota Upper Control Arm, Driver Side

Part Number: 48630-35030$223.32 MSRP: $318.85You Save: $95.53 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Arm Assembly, Suspension; Suspension Control Arm, Front Left Upper; Arm Assembly, Front Suspension, Upper Driver Side; Suspension Control Arm; Control Arm

- Position: Upper Driver Side

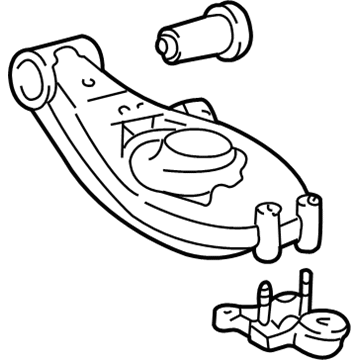

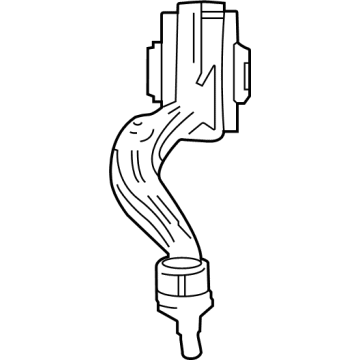

Toyota Lower Control Arm, Driver Side

Part Number: 48069-04030$246.19 MSRP: $351.50You Save: $105.31 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm, Front Left Lower; Control Arm Assembly; Arm Sub-Assembly, Front Suspension, Lower Driver Side; Control Arm

- Position: Lower Driver Side

Toyota Control Arm, Passenger Side

Part Number: 48068-06150$158.26 MSRP: $224.04You Save: $65.78 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm, Front Right; Control Arm Assembly; Lower Control Arm; Arm Sub-Assembly, Front Suspension, Lower Passenger Side; Suspension Control Arm

- Position: Passenger Side

Toyota Lower Control Arm, Passenger Side

Part Number: 48068-13010$162.96 MSRP: $230.69You Save: $67.73 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm, Front Right; Arm Sub-Assembly, Front Suspension, Lower Passenger Side; Suspension Control Arm; Control Arm

- Position: Passenger Side

Toyota Control Arm, Lower Driver Side

Part Number: 48069-06160$174.12 MSRP: $246.49You Save: $72.37 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm, Front Left; Control Arm Assembly; Lower Control Arm; Arm Sub-Assembly, Front Suspension, Lower Driver Side; Suspension Control Arm

- Position: Lower Driver Side

Toyota Upper Control Arm, Passenger Side

Part Number: 48610-35030$194.31 MSRP: $277.43You Save: $83.12 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Assembly, Suspension; Suspension Control Arm, Front Right Upper; Arm Assembly, Front Suspension Upper, Passenger Side; Suspension Control Arm; Control Arm

- Position: Passenger Side

Toyota Lower Control Arm, Driver Side

Part Number: 48069-35110$134.50 MSRP: $190.41You Save: $55.91 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm, Front Left Lower; Arm Sub-Assembly, Front Suspension, Lower Driver Side; Suspension Control Arm; Control Arm

- Position: Lower Driver Side

Toyota Lower Control Arm, Passenger Side

Part Number: 48068-35110$174.48 MSRP: $246.99You Save: $72.51 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm, Front Right Lower; Arm Sub-Assembly, Front Suspension, Lower Passenger Side; Suspension Control Arm; Control Arm

- Position: Passenger Side

Toyota Control Arm, Lower Driver Side

Part Number: 48069-06150$168.13 MSRP: $238.01You Save: $69.88 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm, Front Left; Control Arm Assembly; Lower Control Arm; Arm Sub-Assembly, Front Suspension, Lower Driver Side; Suspension Control Arm

- Position: Lower Driver Side

Toyota Lower Control Arm, Driver Side

Part Number: 48069-13010$162.96 MSRP: $230.69You Save: $67.73 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm, Front Left; Arm Sub-Assembly, Front Suspension, Lower Driver Side; Suspension Control Arm; Control Arm

- Position: Lower Driver Side

Toyota Lower Control Arm, Driver Side

Part Number: 48069-14080$461.81 MSRP: $676.78You Save: $214.97 (32%)Ships in 1 Business DayProduct Specifications- Other Name: Arm Sub-Assembly, Suspension; Control Arm; Arm Sub-Assembly, Front Suspension, Lower Driver Side

- Position: Lower Driver Side

Toyota Upper Control Arm, Rear Driver Side

Part Number: 48790-19025$469.08 MSRP: $687.45You Save: $218.37 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Assembly, Upper Control; Control Arm; Arm Assembly, Upper Control, Rear Driver Side

- Position: Rear Driver Side

Toyota Rear Lower Control Arm, Passenger Side

Part Number: 48660-62011$417.44 MSRP: $611.76You Save: $194.32 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Arm Assembly, Suspension; Control Arm; Arm Assembly, Suspension, Lower Passenger Side

- Position: Passenger Side

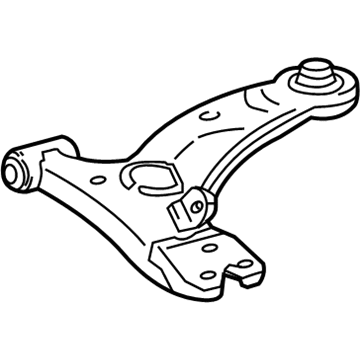

Toyota Lower Control Arm, Passenger Side

Part Number: 48068-35120$212.97 MSRP: $304.08You Save: $91.11 (30%)Product Specifications- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm, Front Right Lower; Arm Sub-Assembly, Front Suspension, Lower Passenger Side; Suspension Control Arm; Control Arm

- Manufacturer Note: (J)

- Position: Passenger Side

- Replaces: 48068-04010, 48068-04011, 48068-35061, 48068-35060

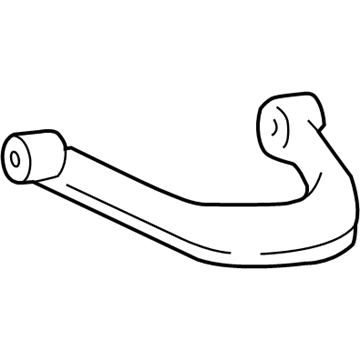

Product Specifications

Product Specifications- Other Name: Arm Assembly, Leading, Front; Control Arm; Front Arm

- Position: Front

- Replaces: 48610-60020

Toyota Control Arm, Lower Driver Side

Part Number: 48069-19105$208.64 MSRP: $297.89You Save: $89.25 (30%)Product Specifications- Other Name: Arm; Arm Sub-Assembly, Front Suspension, Lower Driver Side

- Position: Lower Driver Side

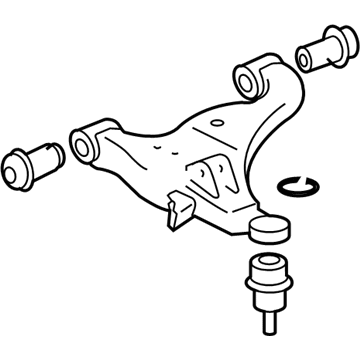

- Product Specifications

- Other Name: Arm Sub-Assembly, Suspension; Lower Control Arm; Arm Sub-Assembly, Front Suspension, Lower Driver Side

- Position: Lower Driver Side

- Product Specifications

- Other Name: Arm Sub-Assembly, Suspension; Suspension Control Arm, Front Right; Arm Sub-Assembly, Front Suspension, Lower Passenger Side; Control Arm

- Position: Passenger Side

| Page 1 of 18 |Next >

1-20 of 347 Results

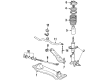

Toyota Control Arm

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Control Arm? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

Toyota Control Arm ensures that the wheel is in line and also the suspension follows the bumps without any drama. Toyota is a company that thrives on lean production that reduces wastage, enables line workers to intercept defects early and pours savings into research that is eventually experienced by ordinary drivers on the road. With its modular TNGA platform, which is a ubiquitous backbone shared among compacts and SUVs, simplifies assembly, lowers the cost, reduces the mass, decreases the center of gravity, and sharpens the turn-in without affecting ride comfort, Toyota raised the bar. Whether it is raining or not, cornering is flatter and braking is straight. Toyota now tripled the hybrids, introducing better batteries, more powerful electric motors, and a Prius platform now overflowing into virtually any body style showing that efficiency could be paired with roughness at least as far as the hour hand. When there is reduced fuel consumed, it means that there are increased funds to use in road trips. The second Control Arm can also be known as a wishbone and is connected to the wheel hub via a unibody pivot that allows the tire to swing in a clean vertical arc. Stamped steel is applied in daily driving and cast aluminum resists corrosion and casts its weight, which furnishes the Control Arm with a higher endurance when potholes hit at high speed. The payoff is experienced by the drivers as a steady Control Arm sustains the camber and toe, prevents the shimmy, and maintains the steering feedback sharp on torn pavement. Worn out bushings or ball joints will make a fresh Control Arm purchase calm, and the owners of Toyota can upgrade their power options to have better high-speed control.

Toyota Control Arm Parts and Q&A

- Q: How to remove and install the upper control arm on 2003 through 2009 Toyota 4Runner?A:Loosen the wheel lug nuts, raise the front of the vehicle, and support it securely on jackstands while applying the parking brake before removing the wheel. Disconnect the wheel speed sensor wiring harness and separate it from the upper control arm and steering knuckle. For clearance to remove the upper arm pivot bolt, take off the wire harness bracket, which is mounted where the bracket meets the body. Support the lower control arm with a floor jack, then remove the retaining clip and loosen the upper balljoint nut about 1/4 inch. Use a two-jaw puller or a balljoint separator to detach the balljoint from the steering knuckle, ensuring the steering knuckle does not fall outward to avoid damaging the brake hose; tying it to the coil spring can help prevent this. Remove the nut, washer, and pivot bolt to detach the upper control arm from the frame, being cautious not to damage the splash shields on each side of the control arm, which can be removed by prying out the fasteners if necessary. Inspect the bushings for wear and deterioration, and if they are cracked or damaged, take the arm to an automotive machine shop for new bushings. Installation follows the reverse order of removal, ensuring all suspension fasteners are tightened to the specified torque and using a new retaining clip on the upper control arm balljoint nut. If needed, tighten the balljoint nut further to align the hole in the ballstud with the slots in the nut without loosening it. The pivot bolt nut should be tightened with the vehicle at normal ride height, which can be achieved after lowering the vehicle or by raising the lower control arm with a floor jack. Finally, tighten the lug nuts to the specified torque and consider having the wheel alignment checked and adjusted if necessary.

- Q: How to remove and install a rear lower control arm on Toyota Sequoia?A:Always support the lower control arm before removing the lower shack mounting bolts, because the lower control arm will drop about 3 inches. Inspect the bushings for wear and deterioration. If they're cracked or damaged, take the arm to an automotive machine shop and have new bushings installed. Loosen the rear wheel lug nuts, raise the rear of the vehicle and support it securely on jackstands. Block the front wheels to keep the vehicle from rolling off the stands. Remove the wheel. Remove the rear shock absorber. Make alignment marks on the front and outer adjusting cams. Hold the adjusting cam plate nuts with a wrench and unscrew the pivot bolts and rear bolt. Remove all the bolts and detach the lower control arm from the frame. Installation is the reverse of removal. Make sure that the alignment marks you made prior to disassembly are lined up. Tighten all suspension fasteners. The pivot bolts should be tightened with the vehicle at normal ride height. This can be done after the vehicle has been lowered to the ground (on vehicles with adequate clearance), or can be simulated by raising the lower control arm with a floor jack. Remove the rear coil spring or air bag. If equipped remove the rear air bags assembly. Remove the cotter pin, then loosen the lower balljoint nut a few turns. Using a two-jaw puller or a pickle fork-type balljoint separator, separate the balljoint from the lower control arm. Make alignment marks on the adjusting cams. Hold the adjusting cam plate nut with a wrench and unscrew the bolt. Remove all the bolt and detach the lower control arm from the frame. Installation is the reverse of removal. Make sure that the alignment marks you made prior to disassembly are lined up. Tighten all suspension fasteners. The pivot bolts should be tightened with the vehicle at normal ride height. This can be done after the vehicle has been lowered to the ground (on vehicles with adequate clearance), or can be simulated by raising the lower control arm with a floor jack.

Related Toyota Parts

Browse Toyota Control Arm by Models

Tacoma 4Runner Camry Tundra Corolla RAV4 Highlander Prius Sienna Land Cruiser Pickup FJ Cruiser 86 Sequoia T100 Avalon Celica Supra Yaris MR2 Matrix Solara Venza GR86 Echo C-HR Cressida Grand Highlander Paseo Previa Prius C Prius Prime Corolla Cross Corolla iM Crown GR Corolla MR2 Spyder Mirai Prius V Starlet Tercel Van Yaris iA bZ4X Prius Plug-In GR Supra Prius AWD-e RAV4 Prime