×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

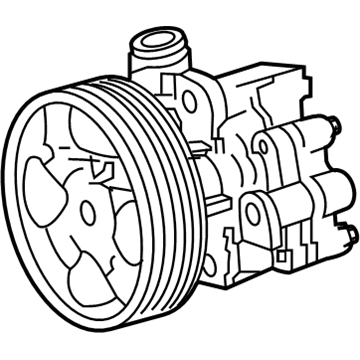

OEM Toyota Power Steering Pump

Power Steering Pump Unit- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

135 Power Steering Pumps found

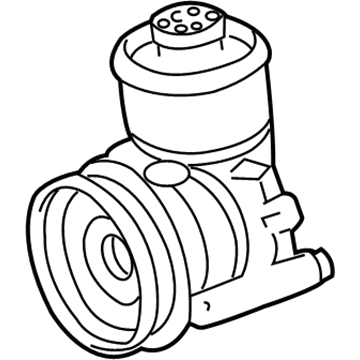

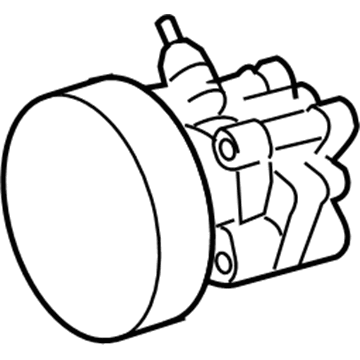

Toyota Power Steering Pump

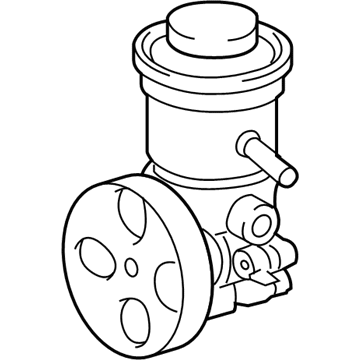

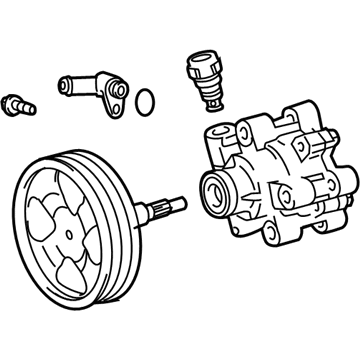

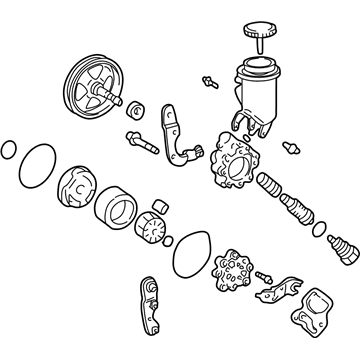

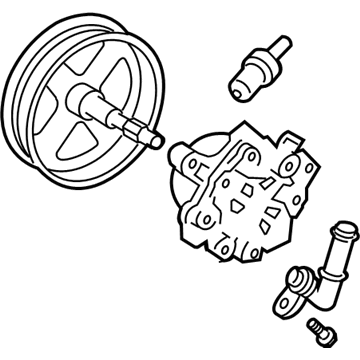

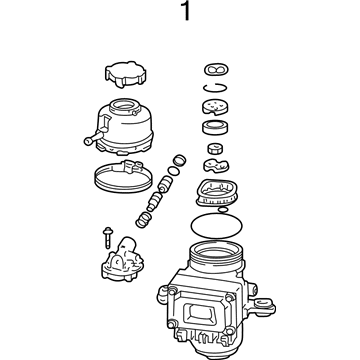

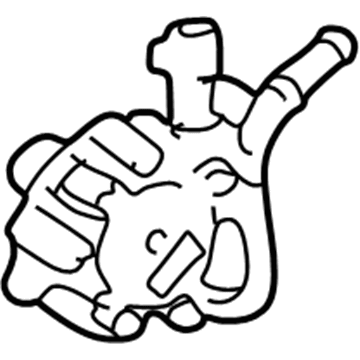

Part Number: 44310-04100$351.16 MSRP: $514.63You Save: $163.47 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump Assembly, Vane; Pump

Toyota Power Steering Pump

Part Number: 44310-01030$292.29 MSRP: $417.32You Save: $125.03 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, Vane

Toyota Power Steering Pump

Part Number: 44310-06110$340.75 MSRP: $486.52You Save: $145.77 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, Vane

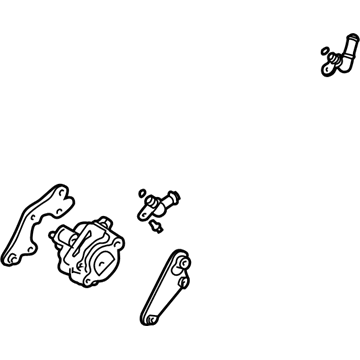

- Manufacturer Note: TYPE B:REFER TO ILLUSTRATION

Toyota Power Steering Pump

Part Number: 44310-04120$388.05 MSRP: $568.68You Save: $180.63 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, Vane

Toyota Power Steering Pump

Part Number: 44310-60490$325.26 MSRP: $464.39You Save: $139.13 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, Vane; Pump

Toyota Pump Assembly, Vane

Part Number: 44310-60390$365.46 MSRP: $535.58You Save: $170.12 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Power Steering Pump

Toyota Power Steering Pump

Part Number: 44320-04020$346.34 MSRP: $494.50You Save: $148.16 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, L/Pulley; Pump Assembly, Vane

Toyota Power Steering Pump

Part Number: 44310-04130$306.03 MSRP: $436.94You Save: $130.91 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, Vane

Toyota Power Steering Pump

Part Number: 44310-52020$366.46 MSRP: $537.05You Save: $170.59 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, Vane; Pump

Toyota Power Steering Pump

Part Number: 44310-04110$403.82 MSRP: $591.80You Save: $187.98 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, Vane; Pump

Toyota Power Steering Pump

Part Number: 44310-0C050$350.93 MSRP: $514.29You Save: $163.36 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, Vane

- Replaces: 44310-0C060

Toyota Power Steering Pump

Part Number: 44320-0W020$325.20 MSRP: $464.31You Save: $139.11 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, L/Pulley; Pump Assembly, Vane

- Replaces: 44320-34050

Toyota Power Steering Pump

Part Number: 44310-0C100$347.98 MSRP: $509.97You Save: $161.99 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, Vane

Toyota Power Steering Pump

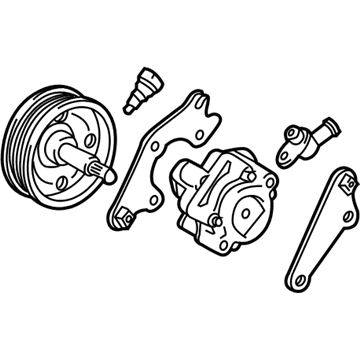

Part Number: 44320-33140$307.66 MSRP: $439.27You Save: $131.61 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, L/Pulley; Pump Assembly, Vane; Pump

- Manufacturer Note: TYPE A:REFER TO ILLUSTRATION

- Replaces: 44320-33150

Toyota Power Steering Pump

Part Number: 44310-06190$367.05 MSRP: $537.91You Save: $170.86 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, Vane; Pump

- Manufacturer Note: (L)

- Replaces: 44310-33190

Toyota Power Steering Pump

Part Number: 44310-60563$317.22 MSRP: $452.91You Save: $135.69 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump Assembly, Vane

- Replaces: 44310-60560, 44310-60561, 44310-60562

Product Specifications

Product Specifications- Other Name: Pump Assembly, Vane W/Mo; Pump Assembly, Vane

Product Specifications

Product Specifications- Other Name: Pump Assembly, Vane

- Product Specifications

- Other Name: Pump Assembly, L/Pulley

- Replaces: 44320-16270

- Product Specifications

- Other Name: Pump Assembly, L/Pulley; Pump Assembly, Vane; Pump

| Page 1 of 7 |Next >

1-20 of 135 Results

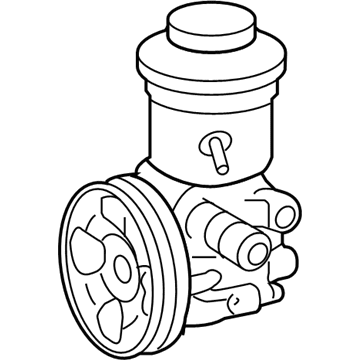

Toyota Power Steering Pump

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Power Steering Pump? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

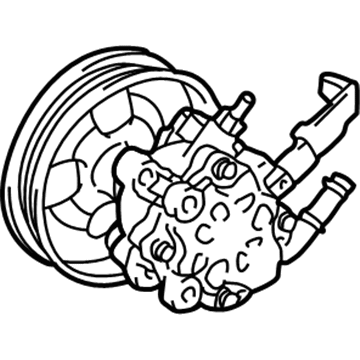

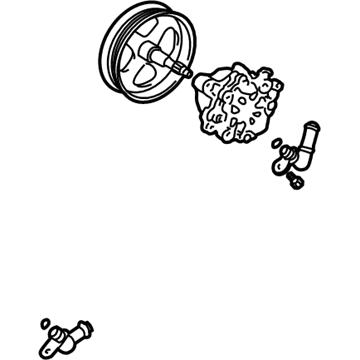

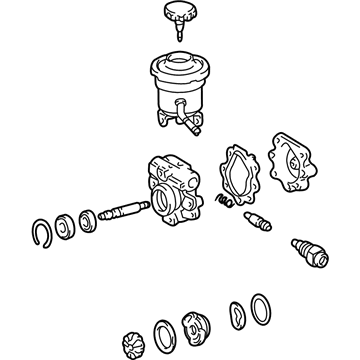

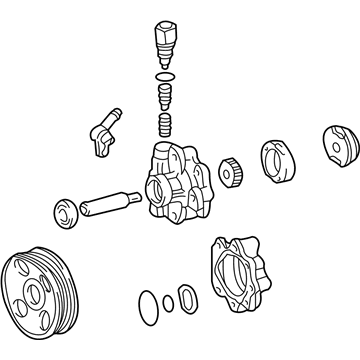

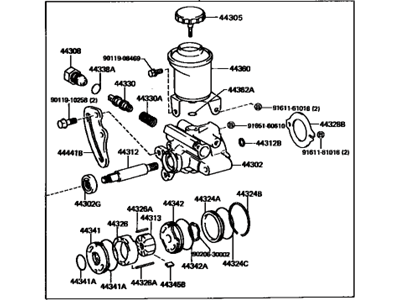

Toyota Power Steering Pump helps make steering a bit easier as drivers flick the wheel easily. Toyota makes cars run lean on the line, employees identify problems early, and maintain quality lean so that cars are coming off the line sustainable, efficient, and prepared to go far, whether it's a small hybrid or a spacious SUV, and the new Hybrid Synergy Drive is squeezing more miles out of each drop and the TNGA platform is making things handle better without adding to the expense. Toyota continues its charge, adding plug-ins to the Prius and extending the range of the RAV4 to 42 miles earning the company a fan that wants to pay less at the pump, but one that still demands a vehicle that drives and a reliability front page, and the company supports this charge with an international supply chain that delivers parts to the market at high speed. The Power Steering Pump is attached to the engine and rotates with the crank and sprays hydraulic fluid into high-pressure hoses to allow a Toyota driver to turn the wheel with two fingers even during parking. Within the pump, fluid is moved through veins into an outlet that services the steering gear; the Power Steering Pump then directs the liquid back to its reservoir to maintain the car cool and responsive and Toyota is fitting the device to sedans, crossovers, trucks, and hybrids. A worn Power Steering Pump squeals under strain, and the wheel feels heavy, with a fresh Power Steering Pump remaining silent and instant, providing the driver with feedback without straining the arm flexing the column around tight turns or during a long turn at high speed.

Toyota Power Steering Pump Parts and Q&A

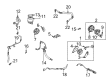

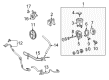

- Q: How to service and repair the power steering pump on Toyota 4Runner?A:Begin the service and repair work on the power steering pump by unscrewing its air cleaner assembly through the removal of three bolts. Before you disconnect the return hose you should remove its clip but keep the drive belt clean from any fluid spillage. The service requires disconnecting the oil pressure switch through connector removal from the pressure feed tube while preventing drops of the switch unit; if damage occurs replace the switch with a new one. You should remove the pressure feed tube by disassembling its union bolt along with the gasket. The drive belt removal process starts by loosening nut "B" and bolt "A" before easing bolt "C." The next step requires the PS vane pump assembly removal through bolt "A" followed by nut "B" before finally removing the whole assembly itself. Beginning with installing the PS vane pump assembly allows you to tighten bolt "A" and nut "B" temporarily before adjusting drive belt tension by tightening bolt "C." Finally, torque bolt "A" and nut "B" to 43 Nm (440 kgf-cm, 32 ft. lbs.). Before tightening the union bolt to 47 Nm (480 kgf-cm, 35 ft. lbs.), install a new gasket and the union bolt onto the pressure feed tube while ensuring that the stopper rests against the PS vane pump body walls. Apply torque of 21 Nm (210 kgf-cm, 15 ft. lbs.) to the installed oil pressure switch on the pressure feed tube before reconnecting the connector by keeping oil away from it. The return hose should be connected while installing the clip before reinstalling the air cleaner assembly using the 3 bolts. Bleeding should occur as the final step in the power steering system maintenance process.

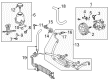

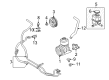

- Q: How to service and repair the power steering pump on Toyota Tacoma?A:The service and repair process for the power steering pump starts by disconnecting the drive belt through unhinging the power steering idle pulley set bolt and the belt adjusting bolt. A spanner (24 mm) should be used to maintain pressure port union stability before removing the union bolt and accompanying 2 gaskets from the pressure feed tube. When removing the return hose take caution to prevent fluid from falling onto the drive belt. You must remove the PS vane pump assembly by unplugging its 2 pump assembly set bolts. The installation begins with attaching the PS vane pump assembly to its 2 bolts while torquing them to 39 Nm (398 kgf-cm, 29 ft. lbs.). Install the pressure feed tube with new gaskets on both sides of the tool before securing the union bolt to 47 Nm (479 kgf-cm, 35 ft. lbs.). While torquing this bolt ensure the tube stopper touches the PS pump body. After properly adjusting the drive belt tension using the belt adjusting bolt you can torque the power steering idle pulley set nut to 39 Nm (398 kgf-cm, 29 ft. lbs.). Apply the final step by performing power steering system bleeding.