×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Echo Power Steering Pump

Power Steering Pump Unit- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Power Steering Pump found

Toyota Echo Power Steering Pump

Part Number: 44310-52020$366.46 MSRP: $537.05You Save: $170.59 (32%)Ships in 1-3 Business Days

Toyota Echo Power Steering Pump

Choose genuine Power Steering Pump that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Power Steering Pump for your Toyota Echo? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Echo parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

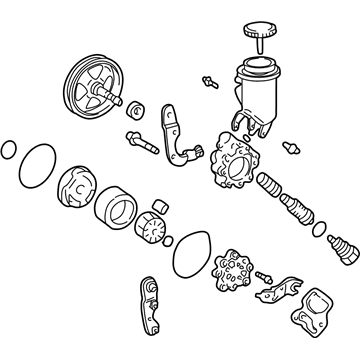

Toyota Echo Power Steering Pump Parts and Q&A

- Q: How to service and repair the power steering pump on Toyota Echo?A:Start power steering pump servicing by first testing the PS vane pump rotating torque while ensuring no irregular noises during the smooth operation and up to a maximum value of 0.27 Nm (2.8 kgf-cm, 2.4 inch lbs.). Drain the oil reservoir by removing its 3 bolts and O-ring and separate the heat insulator from the rear stay. The procedure starts with removing two bolts that secure the front and rear brackets before detaching the pressure port union, flow control valve and spring together with the O-ring from the pressure port union. Disassemble the oil pressure sensor together with its O-ring and after that remove the rear housing and its O-ring. The cam ring, and ten vane plates with the vane pump rotor need careful extraction from the housing but avoid dropping any vane plates and then separate the pair of O-rings attached to the side plate. The maintenance procedure includes removing the vane pump shaft together with its attached vane pump pulley. The measurement of vane pump shaft and bushing oil clearance needs to be performed using both a micrometer and caliper gauge to detect 0.021 - 0.043 mm (0.0008 - 0.0017 inch) standard clearance and 0.07 mm (0.0028 inch) maximum clearance; replace both the front housing and vane pump shaft when results indicate replacement is necessary. Measure the height, thickness and length of vane plate components that must be at least 7.6 mm (0.299 inch), 1.405 mm (0.0553 inch) and 11.993 mm (0.4722 inch) respectively. The groove-clearance measurement between vane plate and vane pump rotor must be under 0.03 mm (0.0012 inch) and replacement is necessary alongside chosen mark identifications. Checking the flow-control valve involves placing power steering fluid on it followed by its smooth insertion into the valve hole accompanied by an air leak test; replacement should be with a valve of the same mark (A, B, C, D, E, or F). You can use vernier calipers to measure the free spring length but you must replace the spring if it falls below 35.8 mm (1.409 inch). Expert maintenance tool: 09950-60010 (09951-00280), 09950-70010 (09951-07100) should be used to properly insert a new oil seal into position after first removing it with a vinyl tape-wrapped screwdriver and applying power steering fluid to the new seal's lip. Reassemble the parts with power steering fluid following the marked locations and install the vane pump shaft with its pulley and side plate featuring two new O-rings which should be coated using the fluid. Proper dent alignment is crucial for this step. Place the vane pump rotor after inserting the cam ring which has its mark facing in the outside direction along with a fresh snap ring. Fasten the rear housing containing a fluid-coated new O-ring while aligning the straight pin and tighten the 4 bolts to 22 Nm (220 kgf-cm, 16 ft. lbs.). The exterior surface of the vane plates must expose their rounded ends during installation. Secure the oil pressure sensor with its new O-ring using torque of 21 nm (210 kgf-cm) before adding the spring and flow control valve together with the pressure port union while ensuring proper alignment of the valve axes and applying fluid-coated O-ring before tightening to 69 nm (700 kgf-cm). First secure front and rear brackets in place by using 2 bolts torqued to 44 Nm (440 kgf-cm, 32 ft. lbs). Afterward attach the heat insulator and rear stay through a bolt torqued to the same value to guarantee proper heat insulator installation. Finally place the oil reservoir with a new fluid-coated O-ring and use 3 bolts torqued to 9.0 Nm (90 kgf-cm, 78 inch lbs). Measure the PS vane pump rotating torque as the last step.