×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

243 Brake Boosters found

Toyota Brake Booster

Part Number: 44610-33510$877.17 MSRP: $1285.51You Save: $408.34 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Booster Assembly, Brake; Power Brake Booster

Toyota Brake Booster

Part Number: 44610-06260$734.45 MSRP: $1076.34You Save: $341.89 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Booster Assembly, Brake; Power Brake Booster; Booster Assembly

- Manufacturer Note: BRAKE PEDAL = TYPE A OR TYPE C

Toyota Booster Assembly, Brake

Part Number: 44610-33690$747.27 MSRP: $1095.14You Save: $347.87 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Brake Booster

- Manufacturer Note: BRAKE PEDAL = TYPE B

Toyota Booster Assembly, Brake

Part Number: 44610-33430$912.00 MSRP: $1336.54You Save: $424.54 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Brake Booster

Toyota Brake Booster

Part Number: 44610-33551$839.75 MSRP: $1230.66You Save: $390.91 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Booster Assembly, Brake; Power Brake Booster

Toyota Brake Booster

Part Number: 44610-33680$656.81 MSRP: $962.57You Save: $305.76 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Booster Assembly, Brake; Power Brake Booster; Booster Assembly

- Manufacturer Note: W(VSC)

Toyota Brake Booster

Part Number: 44610-33670$656.81 MSRP: $962.57You Save: $305.76 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Booster Assembly, Brake; Power Brake Booster; Booster Assembly

Toyota Power Booster

Part Number: 44610-12A80$707.98 MSRP: $1037.55You Save: $329.57 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Booster Assembly, Brake; Brake Booster

- Manufacturer Note: VSC-WITH(W/CUT OFF SWITCH)

Toyota Booster Assembly, Brake

Part Number: 44610-33531$877.47 MSRP: $1285.94You Save: $408.47 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Brake Booster

- Manufacturer Note: W(TRACTION CONTROL)

Toyota Brake Booster

Part Number: 44610-06302$1028.30 MSRP: $1506.98You Save: $478.68 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Booster Assembly, Brake; Power Brake Booster; Booster Assembly

- Replaces: 44610-06301

Toyota Brake Booster

Part Number: 44610-06210$674.63 MSRP: $988.68You Save: $314.05 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Booster Assembly, Brake; Power Brake Booster; Booster Assembly

- Manufacturer Note: BRAKE PEDAL = TYPE B

Toyota Booster Assembly, Brake

Part Number: 44610-33630$875.26 MSRP: $1282.69You Save: $407.43 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Brake Booster

- Manufacturer Note: W(TRACTION CONTROL)

Toyota Power Booster

Part Number: 44610-02440$678.33 MSRP: $994.10You Save: $315.77 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Booster Assembly, Brake; Brake Booster

- Product Specifications

- Other Name: Booster Assembly, Brake

- Replaces: 44610-32030, 44610-32031

- Product Specifications

- Other Name: Booster Assembly, Brake; Actuator Assembly

- Replaces: 44610-33010, 44610-06010, 44610-33230

- Product Specifications

- Other Name: Booster Assembly, Brake; Power Booster; Actuator Assembly

- Manufacturer Note: W(*66)

- Replaces: 44610-33080, 44610-33110, 44610-33070

- Product Specifications

- Other Name: Booster Assembly, Brake

- Product Specifications

- Other Name: Booster Assembly, Brake; Power Brake Booster; Brake Booster

- Manufacturer Note: W(ABS)

- Product Specifications

- Other Name: Booster Assembly, Brake; Power Brake Booster; Booster Assembly

- Manufacturer Note: W(TRACTION CONTROL)

- Product Specifications

- Other Name: Booster Assembly, Brake

- Replaces: 44610-33590

| Page 1 of 13 |Next >

1-20 of 243 Results

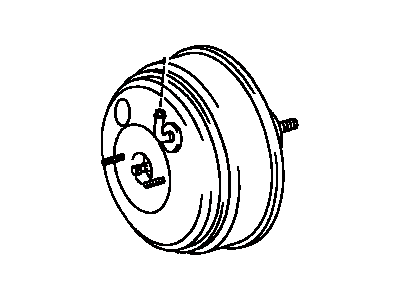

Toyota Brake Booster

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Brake Booster? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

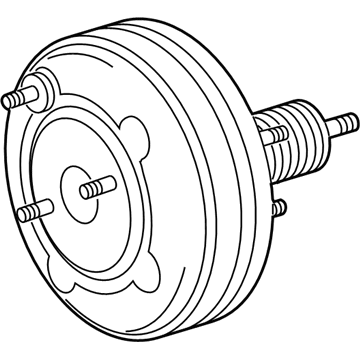

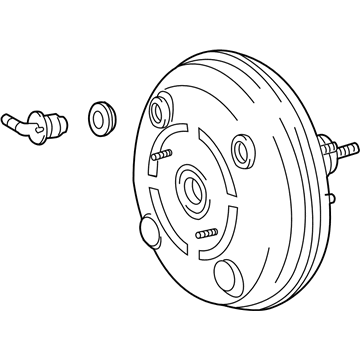

Toyota Brake Booster enhances the force on the pedal to make stops earlier and with much less leg effort. Toyota originated in 1937 Japan and continues to sell all over the globe. Customers have confidence in Toyota due to its Hybrid Synergy Drive, which reduces fuel costs, the TNGA platform, which makes bodies stiff to handle, and plug-in models such as RAV4, which do not sacrifice cabin space and durability. Whether it is compact city cars or heavy-duty SUVs, Toyota brings consistent quality, extended components, and just-like-clockwork maintenance programs that render ownership predictable to families, ride-share companies, and any other person who intends to maintain a car over a decade. Whenever Toyota is revising a model, they seek actual benefits, meaning that hybrids attract more miles per gallon, safety technology responds quicker, and the steering wheel is more precise, yet none of this comes at the cost of adding pounds or complexity. Brake Booster is placed between the driver pedal and the master cylinder and utilizes engine vacuum or hydraulic pressure to multiply the action of the driver and provides the impulse to the blast of brake fluid to ensure that just a light toe tap can accelerate a heavy SUV down a hill. A healthy Brake Booster will have a firm pedal feel; leaks will creep in, and the pedal will become spongy, and the distances of stopping will increase. A replacement of the Brake Booster is required when your foot has to mash deeper due to lost assist, which leads to an increase in panic stops. The difference between hydraulic and vacuum Brake Booster designs is in their source of pressure, but in both cases, the aim is the same, which is to convert tiny muscle into huge clamping power.

Toyota Brake Booster Parts and Q&A

- Q: How to service and repair the vacuum brake booster on Toyota Camry?A:The service and repair of the vacuum brake booster requires a technician to remove sequentially the air cleaner cover and air cleaner hose then master cylinder and charcoal canister. The first step is disconnecting the vacuum hose from the brake booster before you take out the pedal return spring together with its clip and clevis pin. To service the brake booster one must remove its components starting with 4 clevis nuts and clevis which reveals the brake booster and its gasket. Installing the new gasket requires placement before putting the booster into position followed by mounting the booster onto the operating rod using the clevis. Torque the booster installation nuts to 13 Nm (130 kgf-cm, 9 ft. lbs.) and the clevis lock nut to 25 Nm (260 kgf-cm, 19 ft. lbs.). Place the clevis pin through the clevis then brake pedal combination followed by attaching the clip before putting back the pedal return spring. You can set the Special Service Tool: 09737-00010 on the new gasket positioned on the master cylinder so you can lower the pin until it touches the piston lightly. Place the Special Service Tool: 09737-00010 upside down on the booster to measure the clearance between the push rod and pin head while the clearance should equal 0 mm (0 inch). Lengthen or shorten the booster push rod until its end barely contacts the pin head. After reinstalling the charcoal canister together with the master cylinder and air cleaner cover you must secure the air cleaner hose before connecting the vacuum hose to the brake booster. The brake fluid reservoir should receive a refill before the technician completes brake system bleeding while inspecting for fluid leaks. The completion of checks on brake pedal performance and operational testing should be performed as the last step.

- Q: How to install the hydraulic brake booster on Toyota Tacoma?A:As the first step toward installing the hydraulic brake booster you must position a new brake booster gasket onto the unit before tightening the four nuts to 14 Nm (145 kgf-cm, 10 ft-lbf). Use a union nut wrench to attach the 4 brake lines at their correct positions on the hydraulic brake booster. Torque them to 15 Nm (155 kgf-cm, 11 ft-lbf) while the wrench is absent or to 14 Nm (145 kgf-cm, 10 ft-lbf) when using the torque wrench which should remain parallel to the tool. Connect three connectors then install the master cylinder push rod clevis followed by driving the driver side junction block to 8.0 Nm (82 kgf-cm, 71 in-lbf). Finish the work by installing the lower No. 1 instrument panel finish panel and the instrument panel under tray for automatic transmission as well as the instrument panel hole cover for manual transmission. Install the cowl side trim board LH for Regular Cab, Access Cab, Double Cab while moving onto the front door scuff plate LH and then the front floor footrest. To finish the repair, apply torque of 3.9 Nm (40 kgf-cm, 35 in-lbf) to the negative battery terminal cable while performing inspections of brake pedal height and free play and reserve distance and filling the reservoir with brake fluid followed by bleeding procedures for the brake booster using the accumulator pump assembly and the brake line then master cylinder solenoid and finally checking fluid levels and inspecting for leakage and brake master cylinder operation.

Related Toyota Parts

Browse Toyota Brake Booster by Models

Tacoma 4Runner Camry Tundra Corolla RAV4 Highlander Prius Sienna Land Cruiser Pickup Sequoia T100 Avalon Celica Supra Yaris MR2 Matrix Solara Venza GR86 Echo C-HR Cressida Grand Highlander Paseo Previa Prius Prime Corolla Cross Corolla iM Crown GR Corolla MR2 Spyder Starlet Tercel Van Yaris iA GR Supra Prius AWD-e