×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

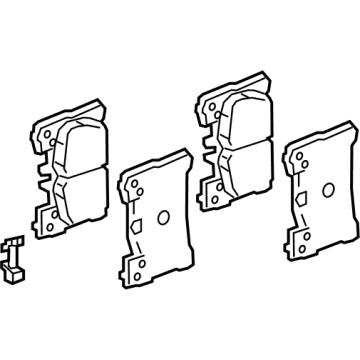

OEM Toyota Brake Pad Set

Disc Brake Pad Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

200 Brake Pad Sets found

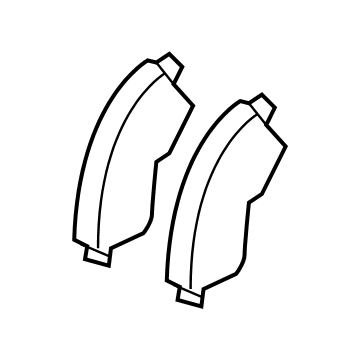

Toyota Brake Pads, Rear

Part Number: 04466-33210$51.98 MSRP: $72.00You Save: $20.02 (28%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Rear; Disc Brake Pad Kit; Rear Pads; Pad Kit, Disc Brake, Rear; Disc Brake Pad Set

- Manufacturer Note: MARK AK NS542

- Position: Rear

Toyota Brake Pads, Front

Part Number: 04465-02410$75.25 MSRP: $104.50You Save: $29.25 (28%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Front; Disc Brake Pad Kit; Front Pads; Pad Kit, Disc Brake, Front; Disc Brake Pad Set

- Position: Front

Toyota Brake Pads, Front

Part Number: 04465-02050$76.07 MSRP: $105.63You Save: $29.56 (28%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake L; Disc Brake Pad Set, Front; Disc Brake Pad Kit; Front Pads; Pad Kit, Disc Brake, Front; Disc Brake Pad Set

- Position: Front

- Replaces: 04465-02040, 04465-12520

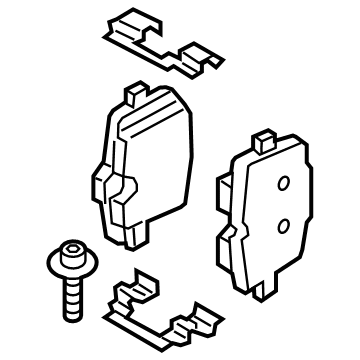

Toyota Pad Kit, Disc Brake, Rear

Part Number: 04466-32030$52.57 MSRP: $72.80You Save: $20.23 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set; Brake Pads

- Position: Rear

Toyota Brake Pads, Front

Part Number: 04465-33340$76.07 MSRP: $105.63You Save: $29.56 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Front; Disc Brake Pad Kit; Front Pads; Pad Kit, Disc Brake, Front; Disc Brake Pad Set

- Manufacturer Note: MARK SUMITOMO PS558H

- Position: Front

- Replaces: 04465-33250

Toyota Pad Kit, Disc Brake, Rear

Part Number: 04466-33090$52.57 MSRP: $72.80You Save: $20.23 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set; Brake Pads

- Manufacturer Note: MARK AK PA544

- Position: Rear

Toyota Brake Pads, Rear

Part Number: 04466-02310$53.78 MSRP: $78.00You Save: $24.22 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Rear; Rear Pads; Pad Kit, Disc Brake, Rear; Disc Brake Pad Set

- Position: Rear

- Replaces: 04466-02270, 04466-02260, 04466-02210

Toyota Brake Pads, Rear

Part Number: 04466-02220$53.78 MSRP: $78.00You Save: $24.22 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Rear; Rear Pads; Pad Kit, Disc Brake, Rear; Disc Brake Pad Set

- Manufacturer Note: MARK ADVICS PS558-FF

- Position: Rear

Toyota Brake Pads, Front

Part Number: 04465-WB001$72.20 MSRP: $103.59You Save: $31.39 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Front; Front Pads; Pad Kit, Disc Brake, Front; Disc Brake Pad Set

- Position: Front

Toyota Brake Pads, Front

Part Number: 04465-33500$85.19 MSRP: $119.58You Save: $34.39 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Front; Disc Brake Pad Kit; Front Pads; Pad Kit, Disc Brake, Front; Disc Brake Pad Set

- Manufacturer Note: MARK AKEBONO NS380H,TRD PACKAGE

- Position: Front

Toyota Brake Pads, Front

Part Number: 04465-02530$90.72 MSRP: $127.34You Save: $36.62 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Front; Front Pads; Pad Kit, Disc Brake, Front

- Manufacturer Note: MARK ADVICS VC084H

- Position: Front

Toyota Brake Pads, Red, Rear

Part Number: 04466-WAA02$79.81 MSRP: $112.03You Save: $32.22 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Rear; Rear Pads; Pad Kit, Disc Brake, Rear

- Position: Rear

Toyota Brake Pads, Red, Rear

Part Number: 04466-WAA03$79.81 MSRP: $112.03You Save: $32.22 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Rear; Rear Pads; Pad Kit, Disc Brake, Rear

- Position: Rear

Toyota Brake Pads, Front

Part Number: 04465-02560$91.71 MSRP: $128.71You Save: $37.00 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Front; Disc Brake Pad Kit; Front Pads; Pad Kit, Disc Brake, Front; Disc Brake Pad Set

- Manufacturer Note: MARK ADVICS VC084H

- Position: Front

Toyota Brake Pads, Front

Part Number: 04465-WAA04$224.38 MSRP: $320.37You Save: $95.99 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Front; Front Pads; Pad Kit, Disc Brake, Front

- Position: Front

- Replaces: 04465-WAA01

Toyota Brake Pads, Front

Part Number: 04465-62010$106.52 MSRP: $149.51You Save: $42.99 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Front; Pad Kit, Disc Brake, Front

- Manufacturer Note: MARK NBK D6504H

- Position: Front

Toyota Brake Pads, Rear

Part Number: 04466-50200$59.95 MSRP: $84.16You Save: $24.21 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Rear; Pad Kit, Disc Brake, Rear

- Manufacturer Note: MARK NBK D6994H

- Position: Rear

Toyota Brake Pads, Front

Part Number: 04465-48230$89.93 MSRP: $126.24You Save: $36.31 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Front; Disc Brake Pad Kit; Front Pads; Pad Kit, Disc Brake, Front; Disc Brake Pad Set

- Manufacturer Note: MARK ADVICS VC084H

- Position: Front

Toyota Front Pads

Part Number: 04465-WAA02$106.26 MSRP: $149.15You Save: $42.89 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Front; Brake Pads; Pad Kit, Disc Brake, Front

- Position: Front

- Product Specifications

- Other Name: Pad Kit, Disc Brake; Disc Brake Pad Set, Front; Front Pads; Pad Kit, Disc Brake, Front

- Manufacturer Note: MARK NBK D6994H

- Position: Front

- Replaces: 04465-F4020

| Page 1 of 10 |Next >

1-20 of 200 Results

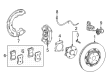

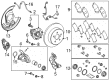

Toyota Brake Pad Set

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Brake Pad Set? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

Toyota Brake Pad Set bites hard and pulls a vehicle down a pace with controlled and reliable capability. The trust Toyota has gained through the tiny waste on the line allows workers to see the trouble when it appears. Toyota continues to go all-hybrid, with plug-in Prius all the way to long-range RAV4, showing that being efficient and durable are not mutually exclusive. Toyota designed the TNGA platform to reduce weight, make bodies rigid, and enhance handling to ensure that each daily commute is nailed to the ground and secure. Options such as Hybrid Synergy Drive upgrade are added to more models annually and therefore even the entry-level trims do not gulp fuel like a thirsty camel. The outcome is a batch that is dependable, cost-effective, and can be applied on road trips of a decade without incident. The options of Brake Pad Set include non-metallic, semi-metallic, and ceramic mixtures all playing off stopping bite, rotor wear, dust output, and cabin quiet. Within each caliper, Brake Pad Set grips the spinning iron with a layer of friction, removes heat, and has wear tabs that squeal when the material is worn out. Brake Pad Set is optimal in swapping when new clips and springs slide in, and each pad is square and will not fade when applied many times. Maintain that between approximately 50,000-mile increments and the Brake Pad Set, the pedal feels firm and the stopping distance tight even after untold commute-hour crawls.

Toyota Brake Pad Set Parts and Q&A

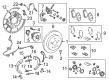

- Q: How to replace the Brake Pad Set on Toyota 4Runner?A:First inspect the pad lining thickness after removing the front wheel through this order: Check if the lining thickness exceeds 1.0 mm (0.039 inch). Replace the pads when the minimum specification is not met. You must separate the clip from the parts along with 2 pins, anti-rattle spring, 2 pads, and 4 anti-squeal shims. However only reuse the anti-rattle spring if it maintains its original condition without damaging cracks and rust or dirt contamination. Conduct a disc measurement check alongside runout inspection before pad installation while you should substitute original anti-squeal shims with new pads. To install the new pads you should tape the monkey wrench handle in advance before pressing brake fluid from the reservoir while using the handle to push in the pistons for each wheel alone to avoid the opposite piston from flying out; loosening bleeder plugs when facing piston resistance allows brake fluid escape. Apply disc brake grease to the inside surfaces of new anti-squeal shims and install both shims in their appropriate positions before putting on the pads without permitting oil or grease to touch the pad contact surface. First install the anti-rattle spring then the two pins followed by the clip and ultimately reinstall the front wheel and tighten it to 103 Nm (1,050 kgf-cm, 76 ft. lbs.). Complete the brake pedal operation a few times to confirm that the fluid rests at the top mark.

- Q: How to Properly Replace a Brake Pad Set on Toyota Tacoma?A:A mechanic must inspect driver brake pad lining thickness through the caliper inspection hole before pad replacement when lining reaches below 1.0 mm (0.039 inch). Lift the caliper into position by taking out the slide pin on the bottom side followed by a secure suspension that does not require flexible hose disconnect. First disconnect both brake pads together with four anti-squeal shims. After removing the pad wear indicator plate the support plates can be reused unless they show visible deformation or cracks or wear or have excessive rust or dirt. Measure disc thickness and runout before putting into place the four pad support plates. The procedure for installing new pads involves swapping both anti-squeal shims and wear indicator plates at the same time using the pads; the technician should install a pad wear indicator plate facing downward on the inner pad before securing two anti-squeal shims on each pad by applying disc brake grease to both sides of the inner anti-squeal shims. Start by placing the inner pad with its wear indicator plate pointing downwards before attaching the outer pad while making sure neither pad comes into contact with oil or grease on the rubbing surface. To press in the piston utilize a brake fluid suction from the reservoir followed by piston compression with appropriate tools such as a hammer handle or equivalent tools. Alternatively, if piston compression proves challenging loosen the bleeder plug to drain some brake fluid before using the compression tools. Apply the brake caliper inside while checking that the boot remains open and then install the slide pin with a torque setting of 88 Nm (900 kgf-cm, 65 ft. lbs.). The final task involves torquing the front wheel to 103 Nm (1,050 kgf-cm, 76 ft. lbs.) then you must press the brake pedal multiple times followed by verification that fluid reaches the maximum line.

Related Toyota Parts

Browse Toyota Brake Pad Set by Models

Tacoma 4Runner Camry Tundra Corolla RAV4 Highlander Prius Sienna Land Cruiser Pickup FJ Cruiser 86 Sequoia T100 Avalon Celica Supra Yaris MR2 Matrix Solara Venza GR86 Echo C-HR Cressida Grand Highlander Paseo Previa Prius C Prius Prime Corolla Cross Corolla iM Crown GR Corolla MR2 Spyder Mirai Prius V Starlet Tercel Van Yaris iA bZ4X Prius Plug-In GR Supra Prius AWD-e RAV4 Prime