×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Sequoia Camshaft Position Sensor

Cam Position Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Camshaft Position Sensors found

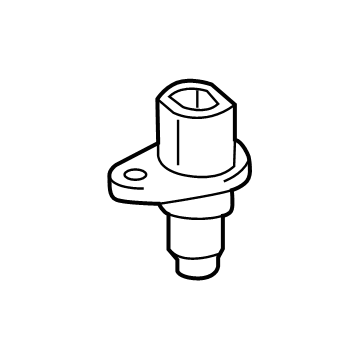

Toyota Sequoia Camshaft Position Sensor, Driver Side

Part Number: 90919-T5005$102.96 MSRP: $144.53You Save: $41.57 (29%)Ships in 1-3 Business Days

Toyota Sequoia Sensor Assembly, Cam Position

Part Number: 19300-50020$162.02 MSRP: $229.35You Save: $67.33 (30%)Ships in 1-3 Business Days

Toyota Sequoia Sensor Assembly, Cam Position

Part Number: 19300-50011$155.09 MSRP: $219.54You Save: $64.45 (30%)Ships in 1 Business DayToyota Sequoia Sensor, Camshaft Position

Part Number: 90919-A5007$103.20 MSRP: $144.86You Save: $41.66 (29%)Ships in 1-3 Business Days

Toyota Sequoia Camshaft Position Sensor

Choose genuine Camshaft Position Sensor that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Camshaft Position Sensor for your Toyota Sequoia? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Sequoia parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

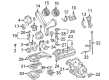

Camshaft Position Sensor in Toyota Sequoia automobiles is an important sensor that signals the position and speed of the camshaft to the engine control module in managing fuel injector and the spark timing. Usually, it is installed in the engine area, more precisely, above the camshaft, but the location can differ depending on the vehicle. Together with the crank sensor, the Camshaft Position Sensor is used to regulate engine components' operations needed for accurate fuel injection timing and accurate measurement of the engine speed. A bad Camshaft Position Sensor can result in slow performance of an automobile's engine; therefore, periodic check-up is crucial.

Toyota Sequoia Camshaft Position Sensor Parts and Q&A

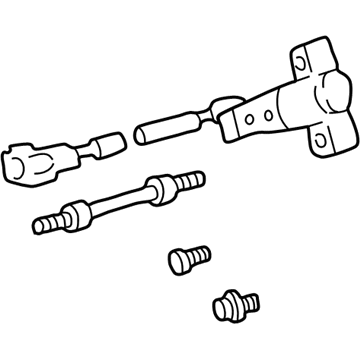

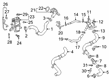

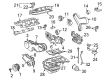

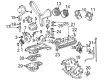

- Q: How to install the camshaft position sensor and related components on Toyota Sequoia?A:Begin the camshaft position sensor installation by using 2 bolts to attach the 2 VVT sensors at 7.5 Nm (76 kgf-cm, 66 in-lbf) torque level before connecting their corresponding sensor connectors. The procedure now requires the Intake Manifold to be installed before moving onto the No. 1 fuel pipe sub-assembly and the No. 2 fuel pipe sub-assembly. The fuel pipe clamp should be installed with the No. 2 water by-pass pipe installed and then a connection of vacuum hose assembly and installation of air cleaner hose assembly. The camshaft position sensor installation must include both a bolt and stud bolt which should be tightened to 7.5 Nm (80 kgf-cm, 66 in-lbf). The installation of Drive Belt follows the complete sequence of attaching the No. 3 timing belt cover sub-assembly LH and connecting the No. 1 radiator hose. Connect the radiator hose while examining the system for fuel and coolant leaks and adding compatible engine coolant to the system. The engine shop should first install the under cover along with throttle body cover and front cowl top outer panel sub-assembly on the No. 1 engine. The installation process ends with adding the front Wiper Motor and link assembly as well as the cowl top ventilator louver sub-assembly and front fender to cowl side seals (both RH and LH components) and finally the front wiper arm and blade assemblies for RH and LH sides.

- Q: How to remove the Camshaft Position Sensor on Toyota Sequoia?A:One must start by discharging the fuel system pressure before beginning the Camshaft Position Sensor removal on a 2UZ-FE engine. The removal process begins with the No. 1 engine under cover followed by engine coolant draining before taking away the throttle body cover sub-assembly. The Drive Belt needs removal first followed by disconnection of the No. 1 radiator hose. First remove the bolting components and entire sensor from the camshaft position sensor before the sub-assembly LH timing belt cover No. 3. The technician should proceed with removing the front wiper aim and blade assembly RH and LH along with the front fender to cowl side seals RH and LH and the cowl top ventilator louver sub-assembly. Rephrase the front Wiper Motor and link assembly, front cowl top outer panel sub-assembly and air cleaner hose assembly. The first task involves disconnecting the vacuum hose assembly and extracting the No. 2 water by-pass pipe. To proceed with the task the next step must involve removing the EFI fuel pipe clamp then disconnecting the No. 2 and No. 1 fuel pipe sub-assemblies followed by removing the Intake Manifold. The conclusion of this process requires disconnecting the 2 VVT sensor connectors then removing the 2 bolts before removing the 2 VVT sensor connectors.