×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Sequoia Neutral Safety Switch

Transmission Neutral Safety Switch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Neutral Safety Switches found

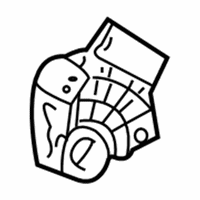

Toyota Sequoia Neutral Safety Switch

Part Number: 84540-0C010$130.77 MSRP: $185.11You Save: $54.34 (30%)

Toyota Sequoia Switch Assembly, Neutral Start

Part Number: 84540-04010$130.77 MSRP: $185.11You Save: $54.34 (30%)Ships in 1-3 Business DaysToyota Sequoia Switch Assembly, Neutral Start

Part Number: 84540-30320$144.40 MSRP: $204.41You Save: $60.01 (30%)Ships in 1-2 Business DaysToyota Sequoia Neutral Safety Switch

Part Number: 84540-0C020$63.27 MSRP: $88.80You Save: $25.53 (29%)Ships in 1-3 Business Days

Toyota Sequoia Neutral Safety Switch

Choose genuine Neutral Safety Switch that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Neutral Safety Switch for your Toyota Sequoia? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Sequoia parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Sequoia Neutral Safety Switch Parts and Q&A

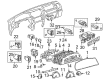

- Q: How to service and repair the Neutral Safety Switch on Toyota Sequoia?A:The transmission oil cooler pipe needs to be disconnected at the beginning of any repair work on the Transmission Position Switch/Sensor. Unplugging the connector is the first step before prying loose the lock washer and progressively taking out the switch and its nut and bolt one after another. The service requires a new Park/Neutral Position Switch and bolt installation following a torque of 13 Nm (130 kgf-cm, 9 ft. lbs.) then the application of a new lock plate and nut with proper 3.9 Nm (40 kgf-cm, 35 inch lbs.) torque and claw bending on the lock plate to maintain nut security. Check the engine operation through the connector by ensuring it starts only during N or P shift lever positions; redo the adjustment if needed. The maintenance continues with pipeline reattachment followed by ATF filling then checking the fluid level and executing a test drive of the vehicle.

- Q: How to remove the Neutral Safety Switch from the A750E automatic transmission / transaxle on Toyota Sequoia?A:The A750E automatic transmission / transaxle Neutral Safety Switch requires its removal to begin with disconnecting the transmission control cable assembly by removing the nut and detaching the cable. The park/neutral position switch assembly requires its switch connector to be detached. The procedure to remove the transmission control shaft lever RH requires the removal of the bolt followed by the lock washer and nut and spring washer. The screwdriver will be used to bend the tabs of the lock washer before removing it along with the lock nut. End the process by taking off the bolt followed by the switch.