×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Drive Shaft

Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

267 Drive Shafts found

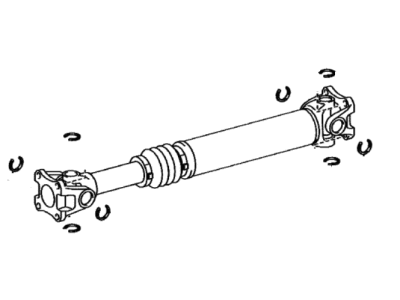

Toyota Drive Shaft, Rear

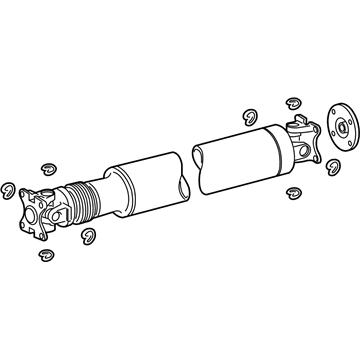

Part Number: 37110-0C210$839.43 MSRP: $1230.20You Save: $390.77 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Drive Shaft Assembly; Shaft Assembly, Propeller, Rear

- Position: Rear

- Product Specifications

- Other Name: Shaft Assembly, Propeller; Driveshaft; Shaft Assembly, Propeller W/Center Bearing

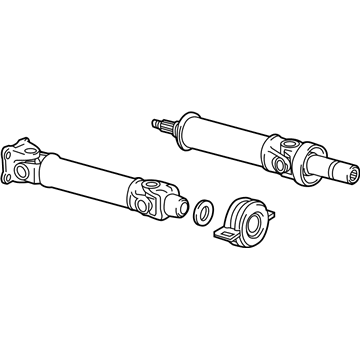

Toyota Drive Shaft

Part Number: 37100-0C175$1504.43 MSRP: $2204.77You Save: $700.34 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly

- Replaces: 37100-0C170, 37100-0C173, 37100-0C174

Toyota Drive Shaft

Part Number: 37100-04371$620.72 MSRP: $909.68You Save: $288.96 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft

- Replaces: 37100-04370

- Product Specifications

- Other Name: Shaft Assembly, Propeller; Driveshaft; Shaft Assembly, Propeller W/Center Bearing

- Replaces: 37120-0C010

Toyota Drive Shaft

Part Number: 37110-3D070$457.05 MSRP: $669.81You Save: $212.76 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft

Toyota Drive Shaft, Rear

Part Number: 37100-0C270$1315.68 MSRP: $1928.14You Save: $612.46 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Drive Shaft, Rear; Drive Shaft Assembly; Shaft Assembly, Propeller, Rear

- Position: Rear

Toyota Drive Shaft

Part Number: 37100-04282$855.32 MSRP: $1253.49You Save: $398.17 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft

- Replaces: 37100-04280, 37100-04281

Toyota Drive Shaft, Front

Part Number: 37140-0C160$390.20 MSRP: $571.85You Save: $181.65 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Shaft Assembly, Propeller, Front

- Position: Front

Toyota Drive Shaft

Part Number: 37110-04182$396.22 MSRP: $580.66You Save: $184.44 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft

- Replaces: 37110-04181, 37110-04180

Toyota Drive Shaft, Rear

Part Number: 37100-04481$897.21 MSRP: $1314.87You Save: $417.66 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Drive Shaft, Rear; Driveshaft; Drive Shaft Assembly

- Position: Rear

- Replaces: 37100-04480

Toyota Drive Shaft

Part Number: 37110-35A80$458.30 MSRP: $671.65You Save: $213.35 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft

Toyota Drive Shaft

Part Number: 37100-0C165$1129.31 MSRP: $1655.02You Save: $525.71 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly; Shaft Assembly, Propeller W/Center Bearing

- Replaces: 37100-0C160, 37100-0C163, 37100-0C164

Toyota Drive Shaft

Part Number: 37100-0C116$998.11 MSRP: $1462.74You Save: $464.63 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Drive Shaft Assembly; Shaft Assembly, Propeller W/Center Bearing

- Replaces: 37100-0C112, 37100-0C113, 37100-0C111, 37100-0C115, 37100-0C110

Toyota Drive Shaft, Front

Part Number: 37140-60300$397.92 MSRP: $583.15You Save: $185.23 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft; Shaft Assembly, Propeller, Front

- Position: Front

Toyota Drive Shaft

Part Number: 37110-35481$496.48 MSRP: $727.60You Save: $231.12 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft

- Replaces: 37110-35480

Toyota Drive Shaft

Part Number: 37100-04273$811.63 MSRP: $1189.45You Save: $377.82 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft

- Replaces: 37100-04271, 37100-04270, 37100-04272

Toyota Drive Shaft, Rear

Part Number: 37100-04411$541.16 MSRP: $793.07You Save: $251.91 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft Assembly, Propeller; Drive Shaft, Rear; Driveshaft; Drive Shaft Assembly

- Position: Rear

- Replaces: 37100-04410

Product Specifications

Product Specifications- Other Name: Shaft Assembly, Propeller; Driveshaft

- Replaces: 37100-04381, 37100-04380

- Product Specifications

- Other Name: Shaft Assembly, Propeller; Driveshaft

- Manufacturer Note: DANA

- Replaces: 37110-3D210

| Page 1 of 14 |Next >

1-20 of 267 Results

Toyota Drive Shaft

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Drive Shaft? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

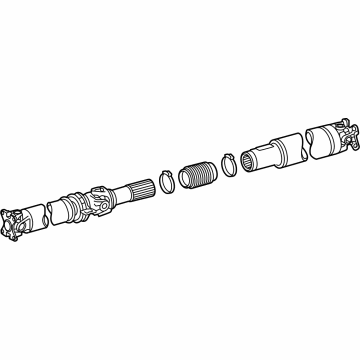

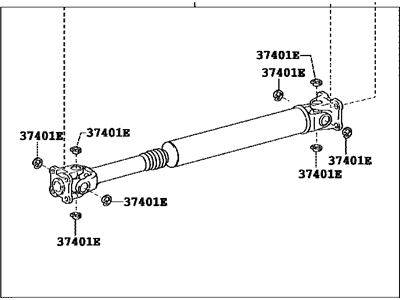

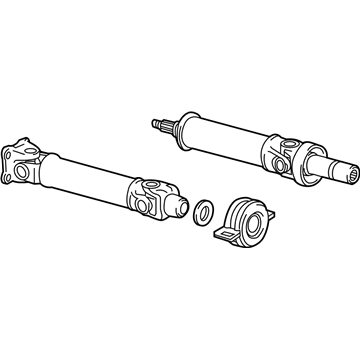

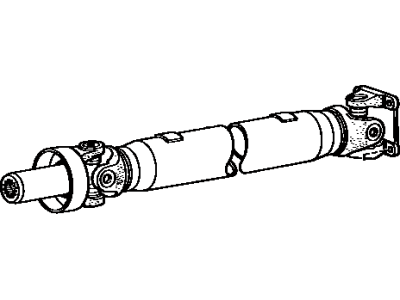

Toyota Drive Shaft provides the engine torque straight to the wheels without any loss of movement. Toyota started in 1937 and currently sells vehicles on all continents due to its value of lean production and rapid issue resolution. The brand cuts waste, identifies problems early, and has assembly lines running full speed to ensure that customers will witness fewer failures. Hybrid Synergy Drive maintains mileage and the TNGA platform reduces weight, improves handling, and enhances crash safety without increasing the cost. Between 2024 and 2029 a plug-in RAV4 increased all-electric range to 42 miles, continuing to show steady increases in usable efficiency and exhibiting an incremental innovation habit. The constant hybrid changes demonstrate that the company does not like to remain stagnant. Drivers remain loyal to Toyota due to the long-lasting parts that shake off the abuse on a daily basis as well as on long-distance journeys. The Drive Shaft comes into play when away from the body shell; it is the solid connection between transmission and the axles and it turns rotary power into forward motion as the suspension bends over potholes or rocky washes. Drive Shafts are hard steel tubes with universal joints which can be changed with an angular motion without shaking. Slip joint Drive Shaft designs fold on hard hits to sever injuries and save the lives of passengers. Multi-piece designs divide the load in the frame such that Toyota SUVs will not vibrate when tackling steep grades. A properly balanced Drive Shaft will minimize power loss, bearings stay cool and four-wheel systems can share torque in a clean fashion. This dependability forms the basis of Toyota trust on the highways and even in the trails.

Toyota Drive Shaft Parts and Q&A

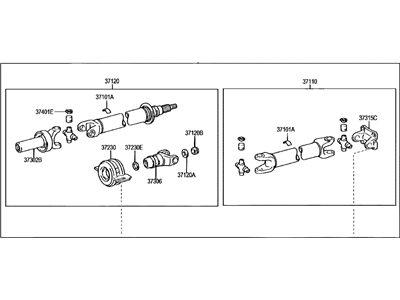

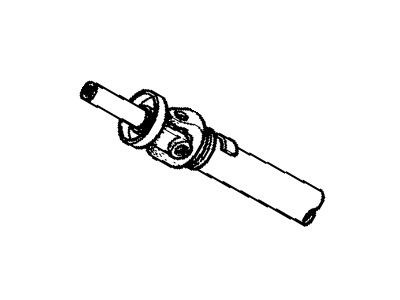

- Q: How to disassemble the Drive Shaft assembly on Toyota 4Runner?A:The first step to disassemble the 2WD propeller shaft assembly is marker application on the flange yoke and sleeve yoke surfaces. Start by using a brass bar and a hammer to insert lightly the spider bearing outer races before removing the 4 snap rings from their grooves using two screwdrivers. Use Special Service Tool: 09332-25010 to extract the spider bearing out of the propeller shaft while raising part (A) sufficiently to prevent spider bearing interference. Place the spider bearing outer race in a vise while hammering the propeller shaft to extract it. Perform this operation again for the other side of the bearing while making sure to avoid contact with the shaft. Special Service Tool: 09332-25010 should be used to push out the spider bearing from the yoke after installing the 2 removed spider bearing outer races to the spider. The operation should ensure that part (A) remains raised. Use a vise to clamp down the outer bearing race before you tap off the yoke with a hammer in order to remove the spider.

- Q: How to Service and Repair a Drive Shaft Assembly on Toyota Tacoma?A:The propeller shaft assembly repair process starts with universal joint spider bearing wear and damage inspection followed by yoke shaft axial movement checks with no limit greater than 0 to 0.05 mm (0 to 0.002 in.) or the bearing must be replaced. The propeller shaft and universal joint yoke require matchmarking before applying a brass bar with a hammer to tap in the spider bearing. Utilize Special Service Tool: 09332-25010 along with a vise and aluminum plates to remove the spider bearing from the propeller shaft after dismantling 4 snap rings from their grooves through the use of needle-nose pliers. Raise the indicated part (A) completely to prevent spider bearing contact with this piece. Place the eliminated spider bearing outer race into a vise clamp while you tap the propeller shaft to discard the bearing but never strike the shaft tube. You should perform the operation again from the alternative side if required. Use Special Service Tool: 09332-25010 to push the bearing out from the yoke while verifying that part (A) rises adequately above the spider bearing. Place the outer bearing race into the vise before hitting the yoke with a hammer to remove the spider. To push the spider bearing from the flange yoke you need to mark the yoke and sleeve yoke for alignment then insert the bearing followed by snap ring removal with pliers while clamping the propeller shaft in a vise. Finish the task with Special Service Tool: 09332-25010 and follow the same procedure steps as previous instructions. Place the flange yoke and spider from the propeller shaft onto a vise before pushing the bearing out from the yoke through Special Service Tool: 09332-25010 while keeping the indicated part (A) at its highest position. Place the outer bearing race into a vise to complete the process by hammer-tapping the yoke until the spider becomes removable. The removal process for center support bearing assembly No. 2 requires fixing the yoke in the center bearing section of a vice then unstaking the lock nut with a chisel and hammer while applying matchmarks to yoke and shaft before applying a brass bar with hammer to extract the center yoke and spacer along with center support bearing from the intermediate shaft.