×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

28 Universal Joints found

Product Specifications

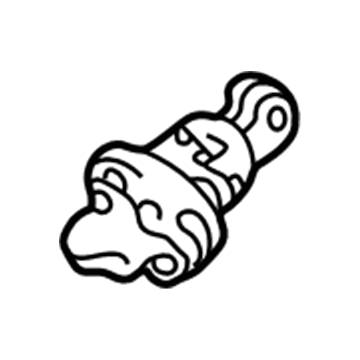

Product Specifications- Other Name: Joint Assembly, Steering; Steering Shaft Universal Joint; Coupling; Joint Assembly, Steering Shaft Universal

Toyota Joint Assembly, Steering Shaft Universal, Lower

Part Number: 45230-07010$81.75 MSRP: $114.76You Save: $33.01 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Steering

- Position: Lower

- Replaces: 45230-33030

Toyota Universal Joints

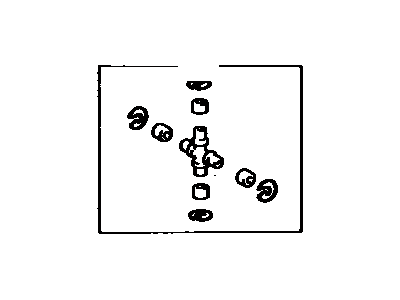

Part Number: 04371-22010$38.47 MSRP: $53.54You Save: $15.07 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spider Kit; CV Joint; U Joint; Spider Kit, Universal Joint(For Propeller Shaft); Spider Kit, Universal Joint

- Manufacturer Note: R JOINT

- Replaces: 37411-20011, 04371-20010, 37411-20010

Product Specifications

Product Specifications- Other Name: Spider Kit, Universal; Universal Joint; CV Joint; U Joint

- Replaces: 04371-36020, 04371-36030, 04371-36021

Toyota Universal Joints

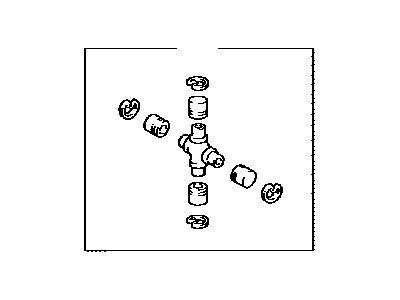

Part Number: 04371-25010$65.64 MSRP: $92.13You Save: $26.49 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spider Kit; CV Joint; U Joint; Spider Kit, Universal Joint(For Propeller Shaft); Spider Kit, Universal Joint

- Manufacturer Note: *AXC=G392 OR G282

- Replaces: 04371-30010, 37401-39010, 04371-30011, 37411-30020

Toyota Universal Joints

Part Number: 04371-0C084$67.30 MSRP: $94.46You Save: $27.16 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spider Kit, Universal; CV Joint; U Joint; Spider Kit, Rear Propeller Shaft Universal Joint

- Replaces: 04371-0C081, 04371-0C080, 04371-0C094, 04371-0C093, 04371-0C082, 04371-0C090

Toyota Universal Joints, Rear

Part Number: 04371-0C095$63.92 MSRP: $89.72You Save: $25.80 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spider Kit, Universal; Universal Joint, Rear; U-Joint

- Position: Rear

Toyota Universal Joints

Part Number: 04371-0C101$65.52 MSRP: $91.96You Save: $26.44 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spider Kit, Universal

Toyota Universal Joints

Part Number: 04375-0C043$60.19 MSRP: $84.48You Save: $24.29 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spider Kit, Universal; Spider Kit, Front Propeller Shaft Universal Joint

Toyota Universal Joints

Part Number: 04375-0C042$60.19 MSRP: $84.48You Save: $24.29 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spider Kit, Universal; U Joint; Spider Kit, Front Propeller Shaft Universal Joint

- Replaces: 04375-0C030, 04375-0C041, 04375-0C020, 04375-0C040

Toyota Universal Joints

Part Number: 04371-04101$60.78 MSRP: $85.31You Save: $24.53 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spider Kit, Universal; CV Joint; U Joint; Spider Kit, Rear Propeller Shaft Universal Joint

- Replaces: 04371-04100

Toyota Universal Joints

Part Number: 04371-04092$66.82 MSRP: $93.80You Save: $26.98 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spider Kit, Universal; CV Joint; U Joint

- Replaces: 04371-0K070, 04371-04090

Toyota Universal Joints

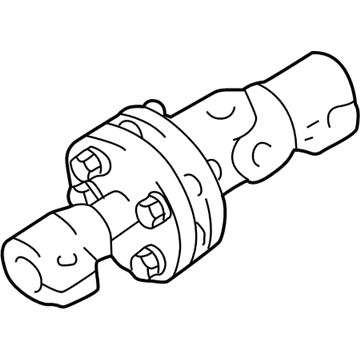

Part Number: 37310-WAA03$143.06 MSRP: $202.51You Save: $59.45 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Assembly, Universal; Coupling, Flexible

Toyota Universal Joints

Part Number: 37310-WAA02$113.10 MSRP: $158.75You Save: $45.65 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Universal; CV Joint; U Joint

Toyota Spider Kit, Universal

Part Number: 04371-60221$53.52 MSRP: $74.50You Save: $20.98 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: SPIDER KIT, UNIVERSA

Toyota Joint Assembly, Steering Shaft Universal

Part Number: 45230-50020$8.35 MSRP: $11.63You Save: $3.28 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Steering

- Replaces: 45767-50010

Product Specifications

Product Specifications- Other Name: Joint Assembly, Steering

- Replaces: 45230-06010

- Product Specifications

- Other Name: Joint Assembly, Steering; Yoke; Coupling; Joint Assembly, Steering Shaft Universal

- Manufacturer Note: W(POWER STEERING)

- Product Specifications

- Other Name: Joint Assembly, Steering; Yoke; Coupling; Joint Assembly, Steering Shaft Universal

- Product Specifications

- Other Name: Spider Kit, Universal; Universal Joint, Rear; U-Joint

- Position: Rear

| Page 1 of 2 |Next >

1-20 of 28 Results

Toyota Universal Joint

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Universal Joint? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

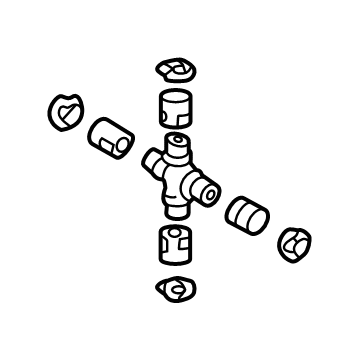

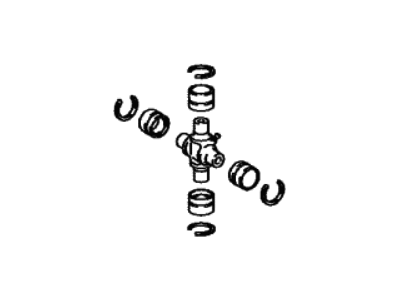

The Toyota Universal Joint is applied to move the spin between the shaft and the differential and flexes with the suspension to maintain a smooth motion. Toyota aims at lean manufacturing that cuts waste, allows line employees to identify defects in the production line, and invests the savings in engine gearboxes that consume less fuel but remain robust, and this is a discipline that was taught in 1937 Japan and refined through inexorable competition across the globe. Toyota continues to access Hybrid Synergy Drive and new plug-in systems, combining quick electric power with sound gas engine power to allow drivers to reduce emissions without sacrificing range or everyday utility. Toyota designed the TNGA platform to shift the center of gravity, increase shell rigidity, and tune steering so that commuters could experience a feeling of solid grip, fast reactions, and enhanced crash performance on the streets or twisty backroads. Loyalty is gained due to the fact that Toyota cars have long range, endure abuse, and remain affordable to buy, leading the initial user to become a lifetime fan across continents and weather conditions. The Universal Joint is between driveshaft and axle yokes, with a cross trunnion and needle bearings to allow the shaft to tilt in two directions as the rotation takes place and eliminate bind when a bump is encountered or the rear axle articulates. Consistent grease changes keep the Universal Joint rolling silently, preventing metal-to-metal grind that would shake cabins and drain power. When play is present or rust blows out cups, when the Universal Joint is very much worn and causes bothersome vibration and clunks, drivers should beware before the shafts shear. Replacement of a new Universal Joint will resume straight torque flow, smoother steering feel, and the confident silence that characterizes a well-maintained ride.

Toyota Universal Joint Parts and Q&A

- Q: How to replace the universal joint on Toyota Land Cruiser?A:Before starting universal joint replacement start by removing the propeller shaft and marking corresponding positions on the shaft and flange yoke and between flange yoke and sleeve yoke. Start by separating the sleeve yoke from the propeller shaft. A brass bar combined with a hammer to tap the bearing outer races should be used followed by extracting the four snap rings using two screwdrivers from their grooves. Startup the spider bearing extraction using Special Service Tool: 09332-25010 which pushes the bearing out of the flange while maintaining enough clearance between "A" and the bearing. The outer bearing race should be placed in a vise during this operation while the flange receives hammer taps to remove it and the process should repeat on the other side. After removing the flange yoke from either the sleeve yoke or propeller shaft install the two extracted bearing outer races onto the spider. To push out the bearing from the yoke utilize Special Service Tool: 09332-25010 while using a vise to clamp the outer bearing race followed by hammer tapping of the yoke as performed for the opposite side. Choose the spider bearing by verifying the drill mark on yoke section then apply MP grease on new replacement parts while watching for excessive grease usage. Special Service Tool: 09332-25010 should be used to install the bearings onto the spider while adjusting both bearing snap rings to reach maximum and equal width. Put in two new snap rings with same thickness so the system shows 0 mm (0 inch) axial play after installation while avoiding used rings and tapping the yoke with a hammer until the bearing outer race touches the snap ring. Put matchmarks on the propeller shaft and flange yoke or on the flange yoke and sleeve yoke beforeInstalling the assembly between these components while using two new spider bearings and their snap rings as installed on the previous flange yoke. Confirm the smooth operation of the spider bearing along with its axial play measurement which should stay within the 0 mm (0 inch) bounds and verify proper orientation of the grease fitting assembly hole as shown in the illustration.

- Q: How to service and repair the universal joint on Toyota Tundra?A:Begin universal joint service by first disassembling propeller shaft and intermediate shaft while placing matchmarks on the yoke and propeller shaft before disassembly of center yoke. Begin by positioning the yoke inside a vise for the next step. Use a hammer with a chisel to unstake the nut of the intermediate shaft for center support bearing removal. Then remove the spacer and nut while making matchmarks on both shaft and yoke. A combination of brass bar and hammer permit center yoke, spacer and center support bearing extraction from intermediate shaft components. A dial indicator must be used to inspect the propeller shaft and intermediate shaft for any damage or runout. If maximum runout exceeds 0.8 mm (0.031 inch) either shaft needs immediate replacement. A dial indicator should be used to check the spider bearing because excessive 0.05 mm (0.0020 inch) axial play requires replacement of the bearing component. Examine the center support bearing for smooth operation because replacement is needed when damage or wear is present. During reassembly first install the center support bearing onto the intermediate shaft correctly oriented followed by applying MP grease to the intermediate shaft splines along with installing the spacer and center yoke which needs to be aligned through matchmarks. Replace the intermediate shaft center yoke while maintaining the same orientation of its front yoke side relative to the center yoke. Clamp the yoke into a vise after spacer installation then apply torque of 181 Nm (1,845 kgf-cm, 133 ft. lbs.) to the new nut until the bearing reaches its correct position before loosening and retightening to 82 Nm (835 kgf-cm, 60 ft. lbs.). Finish the procedure by staking the nut using a hammer and punch. The final step in the construction includes yoking the center section between the propeller shaft and the intermediate shaft.