×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

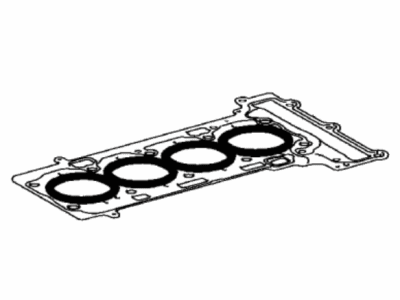

OEM Toyota Cylinder Head Gasket

Engine Cylinder Head Gasket- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

94 Cylinder Head Gaskets found

Toyota Head Gasket

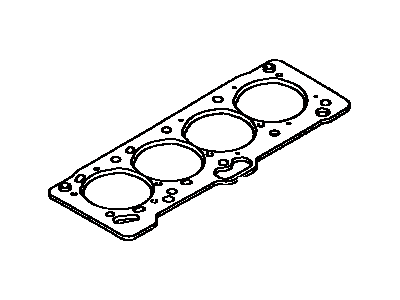

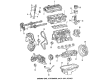

Part Number: 11115-31080$85.78 MSRP: $120.42You Save: $34.64 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Cylinder Head Gasket; Cylinder Head Gasket; Engine Gasket Set

- Replaces: 11115-31060

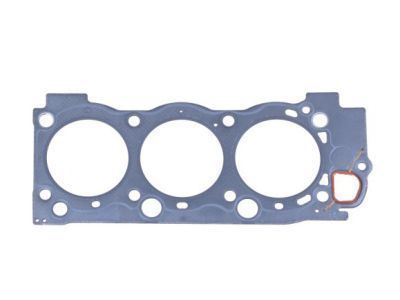

Toyota Gasket, Cylinder Head

Part Number: 11116-0A012$83.65 MSRP: $117.41You Save: $33.76 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Engine Gasket Set; Head Gasket

- Manufacturer Note: (L)

- Replaces: 11116-0A011, 11116-0A010

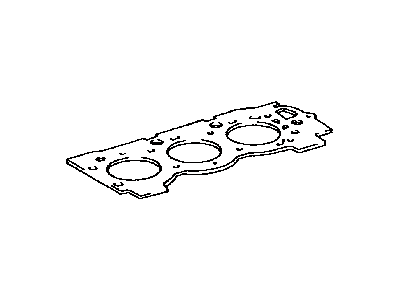

Toyota Gasket, Cylinder Head

Part Number: 11116-31060$69.43 MSRP: $97.46You Save: $28.03 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Engine Cylinder Head Gasket; Engine Gasket Set; Head Gasket

- Replaces: 11116-31040

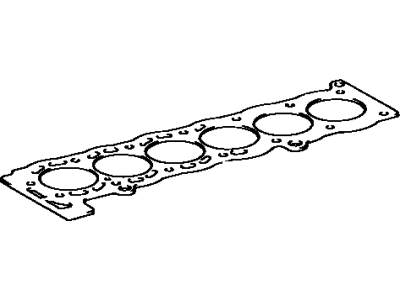

Toyota Head Gasket

Part Number: 11116-62071$69.31 MSRP: $97.29You Save: $27.98 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Cylinder Head Gasket; Cylinder Head Gasket; Engine Gasket Set

- Replaces: 11116-62070

Toyota Head Gasket

Part Number: 11116-20051$72.63 MSRP: $101.94You Save: $29.31 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Cylinder Head Gasket; Cylinder Head Gasket; Engine Gasket Set

- Manufacturer Note: (J)

- Replaces: 11116-20050

Toyota Head Gasket

Part Number: 11115-16121$74.29 MSRP: $104.27You Save: $29.98 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Gasket Set

- Replaces: 11115-16120

Toyota Head Gasket

Part Number: 11115-62071$69.31 MSRP: $97.29You Save: $27.98 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Cylinder Head Gasket; Cylinder Head Gasket; Engine Gasket Set

- Replaces: 11115-62070

Product Specifications

Product Specifications- Other Name: Gasket, Cylinder Head; Engine Gasket Set

- Replaces: 11115-42020

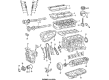

Toyota Head Gasket

Part Number: 11115-74120$96.21 MSRP: $135.05You Save: $38.84 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Cylinder Head Gasket; Cylinder Head Gasket; Engine Gasket Set

Toyota Head Gasket

Part Number: 11115-74081$96.68 MSRP: $135.71You Save: $39.03 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Cylinder Head Gasket; Cylinder Head Gasket; Engine Gasket Set

- Replaces: 11115-74080

Toyota Head Gasket

Part Number: 11115-76040$108.42 MSRP: $152.18You Save: $43.76 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Cylinder Head Gasket; Cylinder Head Gasket; Engine Gasket Set

- Manufacturer Note: T=1.25

- Replaces: 11115-76030

Toyota Head Gasket

Part Number: 11115-28023$71.33 MSRP: $100.12You Save: $28.79 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Gasket Set

- Replaces: 11115-28020, 11115-28022, 11115-28021

Toyota Head Gasket

Part Number: 11115-74070$77.96 MSRP: $109.43You Save: $31.47 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Gasket Set

- Manufacturer Note: T=1.25

Toyota Head Gasket

Part Number: 11115-WAA03$89.44 MSRP: $125.55You Save: $36.11 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Gasket Set

- Manufacturer Note: T=0.81

Toyota Head Gasket

Part Number: 11115-F0030$72.63 MSRP: $101.94You Save: $29.31 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head

- Manufacturer Note: (L)

Toyota Head Gasket, Passenger Side

Part Number: 11115-70070$111.50 MSRP: $156.50You Save: $45.00 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Gasket, Cylinder Head, Passenger Side

- Position: Passenger Side

Toyota Head Gasket

Part Number: 11115-75052$89.34 MSRP: $125.40You Save: $36.06 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Cylinder Head Gasket; Cylinder Head Gasket; Engine Gasket Set

- Replaces: 11115-0C021, 11115-75050, 11115-75051

Toyota Head Gasket

Part Number: 11115-75090$86.85 MSRP: $121.91You Save: $35.06 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Gasket Set

- Replaces: 11115-0C040

Toyota Head Gasket

Part Number: 11115-WAA01$89.56 MSRP: $125.72You Save: $36.16 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gasket, Cylinder Head; Engine Gasket Set

- Manufacturer Note: T=0.80

- Product Specifications

- Other Name: Gasket, Cylinder Head; Engine Gasket Set

- Replaces: 11115-64050, 11115-64070

| Page 1 of 5 |Next >

1-20 of 94 Results

Toyota Cylinder Head Gasket

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Cylinder Head Gasket? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

Toyota Cylinder Head Gasket seals are applied to seal the combustion chambers and prevent the mixture of coolant and oil to keep the engines alive. Toyota evolved into a big company that appreciates waste reduction and problem solving in a very short time. The updates on the Hybrid Synergy Drive by Toyota are evidence that the firm believes in continuous improvement rather than dramatic promises. The Toyota TNGA platform also reduces the center of gravity, narrows down the handling, and enhances crash safety in all its models without weighing them down. Toyota drivers love long-lasting components and hybrid features that extend the fuel range and avoid range anxiety. The brand also released a RAV4 plug-in in 2024 that drives 42 electric miles before taking a drink of gas, demonstrating that durability can achieve current efficiency. The same ethos can be seen in global production lines, and therefore quality remains the same regardless of whether the rollout of the car happens in Aichi or Alabama. The Cylinder Head Gasket is positioned between the block and the head, helping to lock combustion pressure inside and directing the coolant around hot metal, which is super. The Cylinder Head Gasket consists of multi-layer steel sheets that stretch as they go through heat cycles, and hence it can withstand years of explosions, vibration, or even extreme temperatures without being torn. A Cylinder Head Gasket failure spews gases into coolant, ignites a white exhaust, and deprives power at a rate that is faster than any defective spark plug. Easily replace a worn Cylinder Head Gasket, and crooked heads and skyrocketing repair costs will become the order of the day.

Toyota Cylinder Head Gasket Parts and Q&A

- Q: How to replace the Cylinder Head Gasket on Toyota 4Runner?A:The first step to install the Cylinder Head Gasket involves preventing gasoline spills and then removing the chain sub-assembly followed by taking out cool air inlet No.1 bolts and air cleaner hoses and finally removing the transmission oil filler tube sub-assembly by removing the ATF level gauge a bolt and the O-ring. First disconnect the A/F sensor connector and remove 6 nuts to detach the exhaust manifold sub-assembly RH from the exhaust line. Then remove the exhaust pipe assembly front and manifold stay by taking out 3 bolts. The intake manifold must be taken out by disconnecting 6 fuel injector connectors followed by the removal of 10 bolts and 2 gaskets and 6 fuel pipe sub-assemblies No.1 and No.2. To remove the water by-pass joint RR you must first disconnect the engine coolant temperature sensor connector and heater hose while separating 2 bolts and 4 nuts before extracting the water by-pass joint RR together with its 2 gaskets while removing the O-ring from the water outlet pipe. After raising chain tensioner No. 2 and inserting a 1.0 mm pin to keep it stable you must use a wrench to hold the hexagonal camshaft portion while removing 2 bolts and collecting the camshaft timing gear assembly with timing chain No. 2 along with the camshaft timing gear. Take care not to damage the valve lifter and cylinder head. Proper removal procedure requires no.2 chain tensioner assembly followed by cautious removal of the camshafts with maintenance of level orientation to prevent damage. The entire operation requires loose removal of 16 bearing cap bolts in specified order in addition to extraction of 8 bearing caps and 2 camshafts. Perform removal of camshaft bearing No.2 together with the cylinder head sub-assembly by disconnecting two ground cables alongside uniform loosening of eight cylinder head bolts with a 10 mm bi-hexagon wrench and then lift the cylinder head from the dowels on the cylinder block to wooden blocks placement. A vernier caliper measurement of the cylinder head set bolt outside diameter must be performed to check if the measurements fall within standard specifications while working with the removed cylinder head gasket. Cleaning old packing material followed by applying continuous bead of seal packing (Part No. 08826-00080 or equivalent) allows the installation of a new cylinder head gasket with the Lot No. stamp facing upward on the cylinder block surface. The cylinder head sub-assembly installation procedure involves placing the gasket underneath followed by applying engine oil to the cylinder head bolt threads then tightening all bolts equally to 36 Nm before marking the leading bolt side then refitting at 180° as per specifications. Fit bearing No.2 before installing camshafts in a leveled position using fresh engine oil and torquing 16 bearing cap bolts according to the specified values. Position chain tensioner assembly No.2 while aligning marks present on the camshaft timing gears with timing marks then tighten bolts up to 100 Nm. Install the water by-pass joint RR using new O-rings and gaskets and then connect the heater hose along with engine coolant temperature sensor connector. The intake manifold should get installed with new gaskets while tightening bolts to 28 Nm. The procedure includes connecting fuel pipe sub-assemblies No.1 and No.2 followed by exhaust manifold sub-assembly RH installation with a new gasket and a 30 Nm torque on the nuts. This work ends with A/F sensor connector attachment. Install the manifold stay with 3 bolts to 40 Nm and the exhaust pipe assembly front and transmission oil filler tube sub-assembly with a new O-ring which should be tightened to 12 Nm. The last step involves installing the cool air inlet No.1 followed by leak checks for fuel and exhaust gas and use of Special Service Tool: 09843-18030 for idle speed inspection and CO/HC level examination.

- Q: How to remove the cylinder head gasket on Toyota Tundra?A:First clear the 1GR-FE engine from its vehicle then proceed with removing the cylinder head gasket. The installation process requires removal of three devices: ignition coil assembly, spark plug and VVT sensor and the camshaft timing oil control valve assembly. The technician should remove cylinder head cover sub-assemblies beginning with both right and left sides and then continue by removing the engine oil level dipstick guide. To achieve heater water pipe sub-assembly removal start by disassembling two bolts followed by disconnecting three water hoses followed by removing the rear water by-pass joint through harness separation from the engine coolant temperature sensor connector and 2 bolt and 4 nut removal and subsequent separation of the rear water by-pass joint and two gaskets while taking the O-ring from No. 1 water outlet pipe. The maintenance procedure requires removal of the oil control valve filter followed by V-ribbed belt tensioner assembly, No. 2 idler pulley sub-assembly, No. 1 idler pulley sub-assembly and crankshaft pulley. Complete the removal sequence by taking out the No. 2 oil pan sub-assembly, oil strainer sub-assembly and oil pan sub-assembly. You need to separate the No. 2 oil cooler hose and the oil cooler hose followed by uninstalling the water inlet housing, oil filter bracket sub-assembly and timing chain cover sub-assembly. First remove the front crankshaft oil seal before setting the No. 1 cylinder to TDC/compression position. Proceed to remove the No. 1 chain tensioner assembly along with chain tensioner slipper, and the No. 1 idle gear shaft, No. 2 chain vibration damper, No. 1 chain, camshaft timing gears, and No. 2 chain from the machine. Withdraw the No. 2 chain tensioner assembly and both the No. 1 and No. 2 camshafts but maintain a level position during camera removal to avoid damages. The service technician removes each of the 16 bearing cap bolts by their specific sequence and then takes off the 8 bearing caps together with the 2 camshafts. The final task involves cylinder head sub-assembly removal through equal torque bolt loosening of the 8 cylinder head bolts according to sequence followed by lifting the cylinder head from dowels until positioning it on wooden blocks which require surface protection for contact areas. First extract both No. 1 and No. 2 camshaft bearings and proceed to remove the cylinder head gasket.

Related Toyota Parts

Browse Toyota Cylinder Head Gasket by Models

Tacoma 4Runner Camry Tundra Corolla RAV4 Highlander Prius Sienna Land Cruiser Pickup FJ Cruiser 86 Sequoia T100 Avalon Celica Supra Yaris MR2 Matrix Solara Venza GR86 Echo C-HR Cressida Paseo Previa Prius C Prius Prime Corolla Cross Corolla iM GR Corolla MR2 Spyder Prius V Starlet Tercel Van Yaris iA Prius Plug-In GR Supra Prius AWD-e RAV4 Prime