×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Catalytic Converter

Cat. Converter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

397 Catalytic Converters found

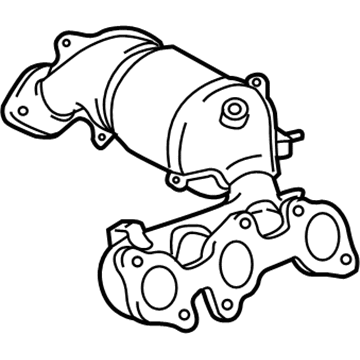

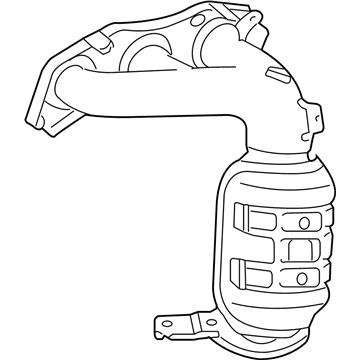

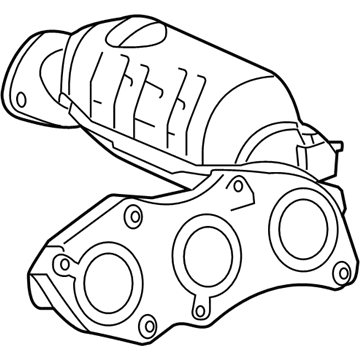

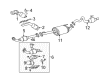

Toyota Exhaust Manifold, Passenger Side

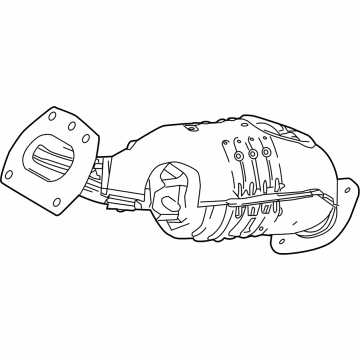

Part Number: 17140-20120$541.72 MSRP: $793.91You Save: $252.19 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Exhaust; Catalytic Converter with Integrated Exhaust Manifold, Right; Manifold Converter; Manifold Sub-Assembly, Exhaust, Passenger Side

- Manufacturer Note: *114=TOYOTA/R20120/Y

- Position: Passenger Side

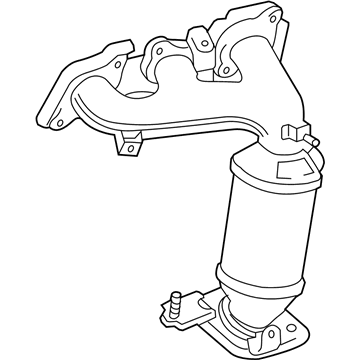

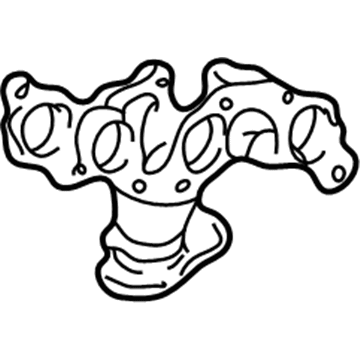

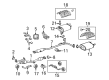

Toyota Manifold Sub-Assembly, Exhaust, Passenger Side

Part Number: 17140-20080$630.25 MSRP: $923.65You Save: $293.40 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Exhaust; Exhaust Manifold

- Manufacturer Note: TYPE B OR TYPE C:REFER TO ILLUSTRATION

- Position: Passenger Side

- Replaces: 17140-20070, 17140-20100

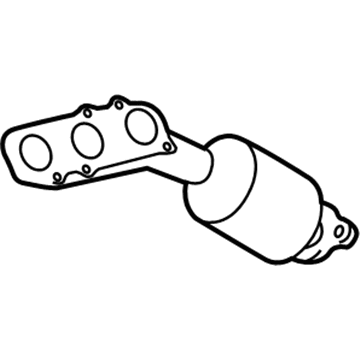

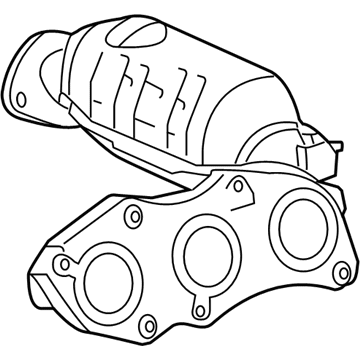

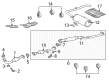

Toyota Exhaust Manifold, Passenger Side

Part Number: 17140-31250$685.76 MSRP: $1004.99You Save: $319.23 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Exhaust; Catalytic Converter with Integrated Exhaust Manifold, Right; Manifold Converter; Manifold Sub-Assembly, Exhaust, Passenger Side

- Manufacturer Note: *114=*565

- Position: Passenger Side

- Replaces: 17140-31070

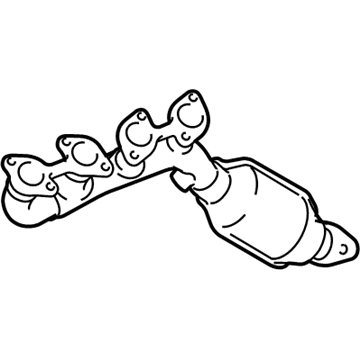

Toyota Exhaust Manifold, Passenger Side

Part Number: 17140-31011$611.53 MSRP: $896.20You Save: $284.67 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold Assembly, Exhaust; Catalytic Converter with Integrated Exhaust Manifold, Right; Manifold Converter; Manifold Sub-Assembly, Exhaust, Passenger Side

- Manufacturer Note: *115=TOYOTA/03-/Y

- Position: Passenger Side

- Replaces: 17140-31010

Toyota Manifold Sub-Assembly, Exhaust, Passenger Side

Part Number: 17104-50180$633.43 MSRP: $928.30You Save: $294.87 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Sub-Assembly, Exhaust; Exhaust Manifold

- Position: Passenger Side

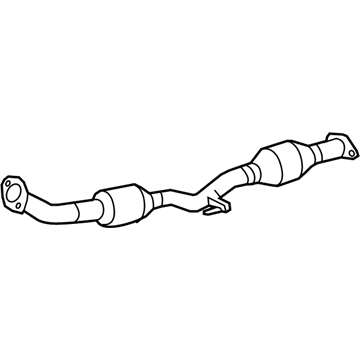

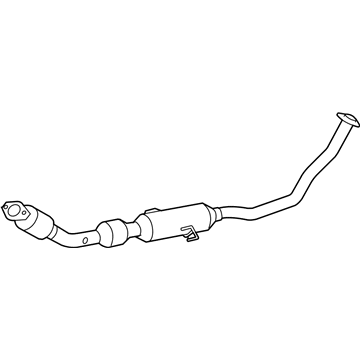

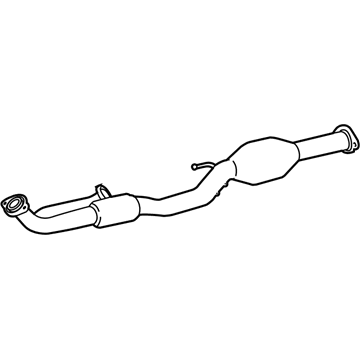

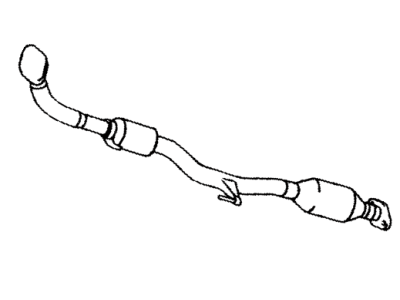

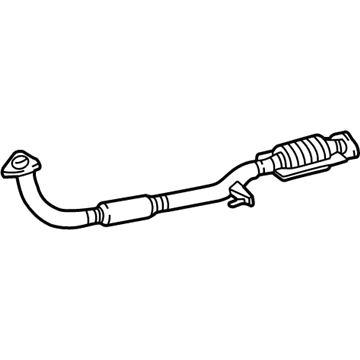

Toyota Front Pipe

Part Number: 17410-0V050$999.70 MSRP: $1341.88You Save: $342.18 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front

Toyota Exhaust Manifold, Driver Side

Part Number: 17150-31160$600.63 MSRP: $880.23You Save: $279.60 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Exhaust; Catalytic Converter with Integrated Exhaust Manifold, Left; Manifold Converter; Manifold Sub-Assembly, Exhaust, Driver Side

- Position: Driver Side

- Replaced by: 17150-31161

Toyota Catalytic Converter, Passenger Side

Part Number: 17140-0P220$554.44 MSRP: $812.53You Save: $258.09 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Exhaust; Catalytic Converter with Integrated Exhaust Manifold, Right; Manifold Converter; Exhaust Manifold; Manifold Sub-Assembly, Exhaust, Passenger Side

- Position: Passenger Side

Toyota Catalytic Converter, Passenger Side

Part Number: 17140-0P250$1006.51 MSRP: $1475.04You Save: $468.53 (32%)Product Specifications- Other Name: Manifold Assembly, Exhaust; Catalytic Converter with Integrated Exhaust Manifold, Right; Manifold Converter; Exhaust Manifold, Passenger Side; Catalytic Converter with Integrated Exhaust Manifold

- Position: Passenger Side

Toyota Exhaust Manifold, Passenger Side

Part Number: 17140-0P350$732.18 MSRP: $1073.01You Save: $340.83 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Exhaust; Catalytic Converter with Integrated Exhaust Manifold, Right; Manifold Assembly, Exhaust, Passenger Side

- Manufacturer Note: *114=TOYOTA/R0P350/Y

- Position: Passenger Side

Toyota Exhaust Manifold, Passenger Side

Part Number: 17104-20030$246.50 MSRP: $351.95You Save: $105.45 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold Sub-Assembly, Exhaust; Exhaust Manifold, Right; Manifold Sub-Assembly, Exhaust, Passenger Side

- Manufacturer Note: CALIFORNIA SPEC

- Position: Passenger Side

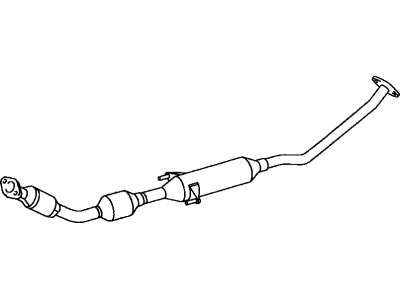

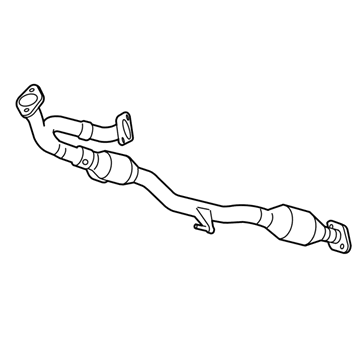

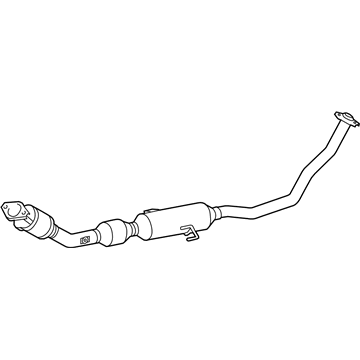

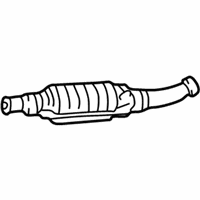

Toyota Converter & Pipe, Front

Part Number: 17410-37420$1412.50 MSRP: $1895.98You Save: $483.48 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front

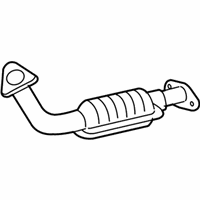

Toyota Front Pipe

Part Number: 17410-22500$1554.94 MSRP: $2087.18You Save: $532.24 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter; Exhaust Pipe; Converter & Pipe; Pipe Assembly, Exhaust, Front

- Position: Front

Toyota Front Pipe

Part Number: 17410-0P380$1171.99 MSRP: $1573.15You Save: $401.16 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter, Rear; Exhaust Pipe; Converter & Pipe; Pipe Assembly, Exhaust, Front; Catalytic Converter

- Position: Front

Toyota Front Pipe

Part Number: 17410-0P351$1022.40 MSRP: $1372.35You Save: $349.95 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter, Rear; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front

Toyota Front Pipe

Part Number: 17410-0H130$2396.65 MSRP: $3217.01You Save: $820.36 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Manufacturer Note: CALIFORNIA SPEC

- Position: Front

Toyota Converter & Pipe, Front

Part Number: 17410-0T560$1376.97 MSRP: $1848.30You Save: $471.33 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter; Exhaust Pipe; Pipe Assembly, Exhaust, Front

- Position: Front

Toyota Front Pipe

Part Number: 17410-0H160$1166.66 MSRP: $1565.99You Save: $399.33 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Catalytic Converter; Exhaust Pipe; Converter & Pipe

- Replaces: 17410-0H020

Toyota Catalytic Converter, Passenger Side

Part Number: 17140-0P270$521.86 MSRP: $764.79You Save: $242.93 (32%)Product Specifications- Other Name: Manifold Assembly, Exhaust; Catalytic Converter with Integrated Exhaust Manifold, Right; Exhaust Manifold; Manifold Sub-Assembly, Exhaust, Passenger Side

- Position: Passenger Side

Toyota Manifold Sub-Assembly, Exhaust, Driver Side

Part Number: 17150-0P150$1184.47 MSRP: $1735.86You Save: $551.39 (32%)Product Specifications- Other Name: Manifold Assembly, Exhaust; Catalytic Converter with Integrated Exhaust Manifold; Catalytic Converter; Exhaust Manifold

- Position: Driver Side

| Page 1 of 20 |Next >

1-20 of 397 Results

Toyota Catalytic Converter

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Catalytic Converter? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

The Catalytic Converter of Toyota reduces toxic exhaust gases in a short period, reducing pollution and maintaining engine performance vigor. Toyota implements lean techniques that identify waste before it happens and enable the assembly lines to change within minutes. Its TNGA platform reduces COG, stiffens the body, and makes the steering sharper for all models around the world. Practitioners examine how hybrid options contribute to the dissemination of compacts, sedans, SUVs, and pickups without compelling the consumer to make trade-offs in terms of space or comfort. Toyota supports such actions by enhancing Hybrid Synergy Drive to ensure that city trips consume less fuel and long-distance journeys remain silent. The 2024 plug-in RAV4 makes the case by having 42 electric miles before the gasoline engine enters the scene. Since high-quality materials combat wear, it means that odometers will turn beyond 200,000 miles before the appearance of even larger repairs. Each Toyota uses the Catalytic Converter that reduces carbon monoxide, hydrocarbons, and nitrogen oxides by reversing them to carbon dioxide, water, and nitrogen. Rare metals such as platinum, palladium, and rhodium are those that cause such reactions and remain unchanged. Housing applies accurate channel geometry to reduce back pressure, hence power and mileage remain unchanged. The Catalytic Converter is connected to flanges on the factory by direct bolts, and it sits tight, installing faster and with minimal clearance codes to protect compliance with emissions. The universal Catalytic Converter slides on shaped pipes and clamps down to allow low-budget constructions to comply with the same clean air regulations. All owners of Toyota vehicles pass through strict global tests without the need to add a special fuel additive or pay full attention to it.

Toyota Catalytic Converter Parts and Q&A

- Q: How to replace the catalytic converter on Toyota Corolla?A:The first step for catalytic converter replacement involves using a jack to lift the vehicle while waiting for the converter to cool down. Unscrew and remove the 2 bolts which secure the exhaust pipe stay while torquing them to 33 Nm (330 kg.cm, 24 ft.lb). The next step requires unscrewing of 2 center exhaust pipe bolts from the tailpipe using 19 Nm (190 kg.cm at 14ft.lb torque. You need to remove the front exhaust pipe bolt and clamp which attaches to the center pipe while torquing them to 32 Nm (320 kg.cm, 24 ft.lb). When replacing the center exhaust pipe extract the two associated gaskets because you will need to install new gaskets before reassembly. Reinstall the converter according to the removal reversal steps.

- Q: How to replace the catalytic converter on Toyota Tundra?A:The heated oxygen sensor (Bank 1) needs removing as the first step in catalytic converter replacement. Unplug the sensor then take it off. The exhaust center pipe requires removal of its four bolts and two springs. Start by removing the RH front exhaust pipe through the procedure of removing its 2 nuts together with the pipe before eliminating the 2 gaskets. The procedure for Bank 2 heated oxygen sensor requires disconnecting its connector and sensor removal. To remove the LH front exhaust pipe you must first disconnect the two nuts and the exhaust pipe support before taking away the pipe and removing the two gaskets. Unbolt the manifold stay through the removal of all its six bolts and two support stays. Begin by disconnecting the A/F sensor (Bank 1) then proceed to remove the exhaust manifold RH by taking off all its 6 nuts along with the gasket. The installer should complete the same procedure for Bank 2 A/F sensor and exhaust manifold LH. Install the exhaust manifold RH by setting it with a new gasket, where the oval opening should point forward and apply 6 nuts evenly with 21 Nm of torque (214 kgf.cm, 15 ft.lbf). The A/F sensor (Bank 1) must be installed with 44 Nm (450 kgf.cm, 33 ft.lbf) torque before connecting its sensor connector. When installing the exhaust manifold LH, orient the new gasket with its oval shape positioned backward then fasten it with 6 nuts which should be tightened to 21 Nm (214 kgf.cm, 15 ft.lbf). The Bank 2 A/F sensor requires installation at 44 Nm torque (450 kgf.cm, 33 ft.lbf) while following up with the sensor connector connection. Screw the manifold stays into place with its 6 bolts and tighten them to 40 Nm (408 kgf.cm, 30 ft.lbf). The LH front exhaust pipe requires installation of new gaskets followed by the pipe and 2 new nuts which need a torque setting of 62 Nm (630 kgf.cm, 46 ft.lbf) before installing the exhaust pipe support. Tighten the heated oxygen sensor (Bank 2) to 44 Nm (450 kgf.cm, 33 ft.lbf) while connecting its sensor connector. The RH front exhaust pipe also requires 2 new gaskets with 2 new nuts that need to be torqued to 62 Nm (630 kgf.cm, 46 ft.lbf). Installing the heated oxygen sensor (Bank 1) requires a torque of 44 Nm (450 kgf.cm, 33 ft.lbf) followed by connecting the sensor connector and attaching the exhaust center pipe by setting 2 bolts to 48 Nm (489 kgf.cm, 35 ft.lbf) and using the 2 bolts and springs which need to be tightened to 43 Nm (440 kgf.cm, 32 ft.lbf).

Related Toyota Parts

Browse Toyota Catalytic Converter by Models

Tacoma 4Runner Camry Tundra Corolla RAV4 Highlander Prius Sienna Land Cruiser Pickup FJ Cruiser 86 Sequoia T100 Avalon Celica Supra Yaris MR2 Matrix Solara Venza GR86 Echo C-HR Cressida Grand Highlander Paseo Previa Prius C Prius Prime Corolla Cross Corolla iM GR Corolla MR2 Spyder Prius V Starlet Tercel Van Yaris iA Prius Plug-In GR Supra Prius AWD-e RAV4 Prime