×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Air Bag Control Module

SRS Airbag Module- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

431 Air Bag Control Modules found

Toyota Diag Unit W/Sensor

Part Number: 89170-0C120$443.09 MSRP: $557.77You Save: $114.68 (21%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Air Bag Sensor; Center Sensor

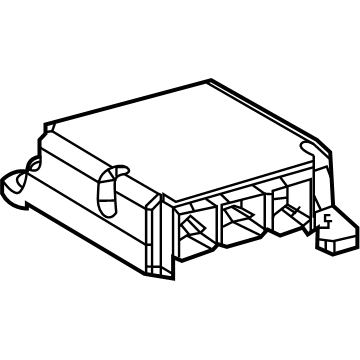

Toyota SDM Module

Part Number: 89170-04210$540.25 MSRP: $680.07You Save: $139.82 (21%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Diag Unit W/Sensor; Computer Assembly, Air Bag

Toyota Diagnostic Module

Part Number: 89170-04040$709.36 MSRP: $892.96You Save: $183.60 (21%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Diagnostic Unit

Toyota Diag Unit W/Sensor

Part Number: 89170-0C110$443.09 MSRP: $557.77You Save: $114.68 (21%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Air Bag Sensor; Center Sensor

Toyota Diag Unit W/Sensor

Part Number: 89170-0C460$386.00 MSRP: $485.91You Save: $99.91 (21%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Air Bag Sensor; Center Sensor

- Product Specifications

- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Diag Unit W/Sensor; Computer Assembly, Air Bag

Toyota SDM Module

Part Number: 89170-04700$370.23 MSRP: $466.04You Save: $95.81 (21%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Diag Unit W/Sensor; Computer Assembly, Air Bag

- Manufacturer Note: MARK TRW

Toyota Diag Unit W/Sensor

Part Number: 89170-0C470$385.21 MSRP: $484.91You Save: $99.70 (21%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Air Bag Sensor; Center Sensor

Toyota SDM Module

Part Number: 89170-04590$376.70 MSRP: $474.19You Save: $97.49 (21%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Diag Unit W/Sensor; Computer Assembly, Air Bag

- Replaces: 89170-04341, 89170-04340

Toyota SDM Module

Part Number: 89170-04510$372.61 MSRP: $469.04You Save: $96.43 (21%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Diag Unit W/Sensor; Computer Assembly, Air Bag

- Replaces: 89170-04252, 89170-04251

Toyota Diag Unit W/Sensor

Part Number: 89170-0C311$430.61 MSRP: $542.06You Save: $111.45 (21%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Air Bag Sensor; Center Sensor

Toyota SDM Module

Part Number: 89170-06A40$424.48 MSRP: $534.34You Save: $109.86 (21%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Diagnostic Unit; Computer Assembly, Air Bag

Toyota SDM Module

Part Number: 89170-02N50$424.48 MSRP: $534.34You Save: $109.86 (21%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Diagnostic Unit; Computer Assembly, Air Bag

Toyota Diag Unit W/Sensor

Part Number: 89170-0C361$443.77 MSRP: $558.62You Save: $114.85 (21%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Air Bag Sensor; Center Sensor

Toyota SDM Module

Part Number: 89170-04180$540.25 MSRP: $680.07You Save: $139.82 (21%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Diag Unit W/Sensor; Computer Assembly, Air Bag

Toyota Diag Unit W/Sensor

Part Number: 89170-04640$348.55 MSRP: $438.76You Save: $90.21 (21%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Computer Assembly, Air Bag

Toyota Passenger Discriminating Sensor, Passenger Side

Part Number: 89952-04022$339.12 MSRP: $484.19You Save: $145.07 (30%)Product Specifications- Other Name: Computer, Occupant Detection; Air Bag Passenger Presence Module; Occupant Module

- Position: Passenger Side

- Replaces: 89952-04021, 89952-04020

- Product Specifications

- Other Name: Sensor Assembly, Air Bag; Diag Unit W/Sensor; Computer Assembly, Air Bag

- Product Specifications

- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Diag Unit W/Sensor

- Manufacturer Note: W(STEEL BUMPER)

- Product Specifications

- Other Name: Sensor Assembly, Air Bag; Air Bag Control Module; Air Bag Sensor; Center Sensor

| Page 1 of 22 |Next >

1-20 of 431 Results

Toyota Air Bag Control Module

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Air Bag Control Module? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

Toyota Air Bag Control Module fires airbags fast, slashing injury risk when a hard crash hits. Toyota is supported by centuries of waste reduction manufacturing, thus the vehicles come out with fewer defects and a longer shelf life, a by-product of its insistent emphasis on identifying issues early and fixing them on the factory floor itself, keeping costs down and quality high. Toyota is retaining its drivers by matching such quality of builds with practical innovation such as Hybrid Synergy Drive, new TNGA frames which stiffen vehicles and reduce centers of gravity and plug-in arrangements which extend a tank more without compelling owners to expensive service. Toyota is also not interested in unleashing its progress with premium badges, as hatchbacks, sedans, crossovers, and pickups all have the same promise of reliability, low fuel bills, and smooth steering on the global market, so young commuters in big city traffic and families crossing the deserts experience the same promise of reliability, low bills, and smooth steering. Within the cabin of any late model, the Toyota Air Bag Control Module sampling crash sensor operates at lightning speed and undergoes self-checks each and every cycle, firing squibs as soon as the split second deceleration surpasses stored limits, protecting heads and chests even before thought has formed. The Air Bag Control Module records crash information to be reviewed later, disregarding small bumps in the parking. The continuous power-on tests allow the Air Bag Control Module to alert the drivers about wiring faults in time. The hard housing ensures the Air Bag Control Module is stable in terms of heat, dust, vibration, and daily jolts.

Toyota Air Bag Control Module Parts and Q&A

- Q: How to service the Air Bag Control Module on Toyota 4Runner?A:The service of the Air Bag Control Module requires careful reading of all Supplemental Restraint System safety precautions. Follow any necessary precautions by disconnecting the negative battery terminal cable. Starting with the console upper rear panel sub-assembly removal you must continue with the console panel sub-assembly upper procedure and subsequently remove the console upper panel garnish No. 1 and No. 2. The service requires removal of the console box assembly rear before you take off the console box mounting bracket front. Unfasten the console box duct No. 1 from the system. The procedure concludes by disassembling the 3 connectors from the center Air Bag sensor assembly before removing its 3 securing bolts.

- Q: How to service the Air Bag Control Module on Toyota Camry?A:Service of the Air Bag Control Module begins with detailed study of restraint system precautions. You should disconnect the negative battery terminal cable and let it rest for 90 seconds to stop Air Bag activation before beginning work. The service begins with removing the shift lever knob sub-assembly and then proceeding to remove the No. 1 and No. 2 instrument cluster finish panel garnishes from both automatic and manual transaxle models. Remove the floor shift position indicator housing sub-assembly for automatic transaxles then continue with removal of the upper console panel and rear panel sub-assemblies for both transaxle types and the front door scuff plates and cowl side trim sub-assemblies, lower instrument panel finish panel, instrument panel No. 2 under cover sub-assembly, console box pocket, carpet, and assembly. Complete removal operations with the No. 1 and No. 2 console box inserts together with the No. 1 console box duct for automatic air conditioning system. After turning back the carpet install the center Air Bag sensor assembly by disconnecting connectors to the holder followed by removal of three bolts. Install the center Air Bag sensor assembly when the ignition is off and negative battery cable is disconnected and use three bolts torqued to 17.5 N.m (179 kgf.cm, 13 ft.lbf). Check for any damage to the assembly during the process. Check that SRS wiring remains free of pinches while inspecting all installation components for security before refitting the holder and examining the water-proof sheet. Continue by installing the No. 1 console box duct, No. 2 and No. 1 console box inserts, console box assembly, carpet, pocket, lower instrument panel sub-assembly, instrument panel No. 2 under cover sub-assembly, cowl side trim sub-assemblies, front door scuff plates, upper console panel and rear panel sub-assemblies for both transaxle types, floor shift position indicator housing sub-assembly for automatic transaxles, No. 2 and No. 1 instrument cluster finish panel garnishes, and the shift lever knob sub-assemblies for both transaxle types. The last step requires attachment of the cable to the negative battery terminal followed by checking the SRS warning light status.

Related Toyota Parts

Browse Toyota Air Bag Control Module by Models

Tacoma 4Runner Camry Tundra Corolla RAV4 Highlander Prius Sienna Land Cruiser FJ Cruiser 86 Sequoia T100 Avalon Celica Supra Yaris MR2 Matrix Solara Venza GR86 Echo C-HR Grand Highlander Paseo Previa Prius C Prius Prime Corolla Cross Corolla iM Crown GR Corolla MR2 Spyder Mirai Prius V Tercel Yaris iA bZ4X Prius Plug-In GR Supra Prius AWD-e RAV4 Prime