×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

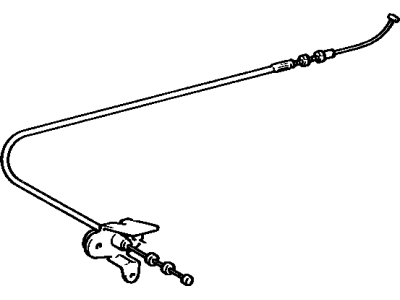

OEM Toyota Throttle Cable

Accelerator Throttle Cable- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

85 Throttle Cables found

Toyota Throttle Cable

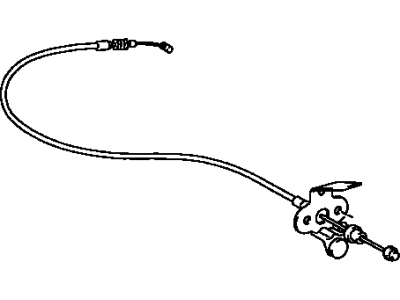

Part Number: 78180-16440$120.36 MSRP: $170.38You Save: $50.02 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

Product Specifications

Product Specifications- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

Toyota Throttle Cable

Part Number: 78180-06110$84.00 MSRP: $117.91You Save: $33.91 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

Toyota Throttle Cable

Part Number: 78180-17410$205.67 MSRP: $293.64You Save: $87.97 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

Toyota Throttle Cable

Part Number: 78180-33040$121.69 MSRP: $172.28You Save: $50.59 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cable Assembly, Accelerator; Control Cable; Cable Assembly, Accelerator Control

- Replaces: 78180-06010

Toyota Throttle Cable

Part Number: 78180-02050$103.56 MSRP: $145.36You Save: $41.80 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

- Manufacturer Note: W(CRUISE CONTROL)

Toyota Throttle Cable

Part Number: 78180-1A801$128.17 MSRP: $181.44You Save: $53.27 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cable Assembly, Accelerator

- Replaces: 78180-1A800

Toyota Throttle Cable

Part Number: 78180-1A520$89.27 MSRP: $125.30You Save: $36.03 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

- Manufacturer Note: (J)

- Replaces: 78180-02030

Toyota Throttle Cable

Part Number: 78180-06140$100.05 MSRP: $140.44You Save: $40.39 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

Toyota Throttle Cable

Part Number: 78180-2D730$149.46 MSRP: $211.58You Save: $62.12 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

- Manufacturer Note: W(CRUISE CONTROL)

Toyota Throttle Cable

Part Number: 78180-01040$120.13 MSRP: $170.07You Save: $49.94 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

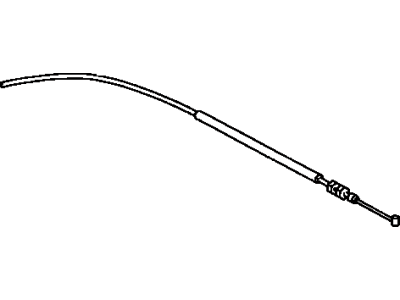

Toyota Throttle Cable

Part Number: 78180-2D760$169.04 MSRP: $239.28You Save: $70.24 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

Product Specifications

Product Specifications- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

Product Specifications

Product Specifications- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

Product Specifications

Product Specifications- Other Name: Cable Assembly, Accelerator; Cruise Control Cable; Cable; Cable Assembly, Accelerator Control

- Manufacturer Note: W(CRUISE CONTROL)

Product Specifications

Product Specifications- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

- Manufacturer Note: W(CRUISE CONTROL)

- Replaces: 78180-06100

- Product Specifications

- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

- Product Specifications

- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

- Product Specifications

- Other Name: Cable Assembly, Accelerator; Accelerator Pedal Position Sensor; Cable Assembly, Accelerator Control

- Manufacturer Note: W(CRUISE CONTROL)

- Product Specifications

- Other Name: Cable Assembly, Accelerator; Cable Assembly, Accelerator Control

| Page 1 of 5 |Next >

1-20 of 85 Results

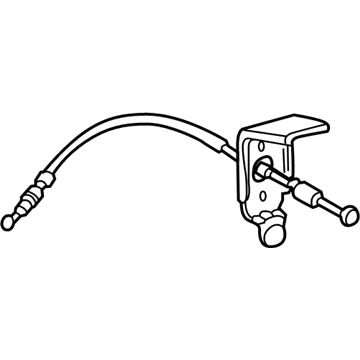

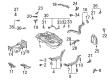

Toyota Throttle Cable

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Throttle Cable? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

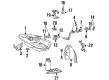

Toyota Throttle Cable connects your pedal with engine airflow to give sharp and reliable response of power. Toyota began in 1937 in Japan and continues to drive lean production which eliminates waste, allows workers to fix problems quickly, and maintain costs reasonable. The firm continues to refine its Hybrid Synergy Drive with the introduction of plug-in technologies that provide actual fuel efficiency without devastating performance. The TNGA platform was implemented by Toyota in order to reduce centers of gravity, make bodies stiffer, and make steering feel more natural. In 2024, the new plug-in hybrid crossover has exceeded 40 electric miles, which is evidence of the brand's tendency to transform laboratory concepts into driveway benefits. Toyota gains the confidence of the long-term due to its ability to endure rough roads, extreme weather, and endless commutes with little hassle in its cars. The drivers in the world today also have a choice of small hatchbacks up to large trucks as they are sure that the same build philosophy is applied throughout its construction. Throttle Cable is a braided cable which converts foot pressure into an accurate swing on the throttle body. The sheath low-stretch steel strands slide over a low-friction liner, thus the Throttle Cable responds immediately rather than bouncing power off the slack. Grit cannot chew the Throttle Cable because there are weather-sealed ends that allow the pedal effort to remain light during an icy winter or dusty summer. Toyota combines this mechanical connection with electronics protection, which is redundancy in favor of safety. Should a Throttle Cable begin binding, its wide clearance and the corrosion-fighting finishes have made movement easy and prevented unexpected surges.

Toyota Throttle Cable Parts and Q&A

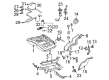

- Q: How to Service and Repair the Throttle Cable on Toyota Camry?A:The first step for servicing throttle cable/linkage work is disconnecting the cable from its linkage while also disassembling the cable clamps located in the engine compartment. Begin by disconnecting the park/neutral position switch and then proceed to take away the valve body. Start the throttle cable service by removing the retaining bolt and plate before taking the cable out from the transaxle case. A new throttle cable requires staking of the stopper or paint mark on the inner cable for a radius size of about 200 mm (7.87 inch) when making the cable bend. Holding the inner cable at which slight resistance appears stake the stopper 0.8 - 1.5 mm (0.031 - 0.059 inch) beyond the outer cable end. The process requires an installation of a new O-ring onto the throttle cable followed by inserting the throttle cable then securing it with the retaining bolt. Reinstallation of the valve body and park/neutral position switch should be followed by attaching the throttle cable and checking and adjusting the fluid level while ensuring a proper throttle cable adjustment.

- Q: How to Service and Repair the Throttle Cable on Toyota Tacoma?A:Start procedures to service and repair the throttle cable/linkage by taking off the throttle cable from the throttle linkage and engine compartment cable clamps before removing the bolt to extract the cable clamp from the torque converter clutch housing. Begin by removing the throttle cable together with the valve body through bolt removal followed by pulling the cable extension. To install new throttle cable bed the cable into a 7.7-inch (200-mm) radius before tensioning the inner cable to generate light resistance that should be maintained when securing the stopper at 0.8 - 1.5 mm (0.031 - 0.059 inches) from the outer cable end. To install the new O-ring on the throttle cable, users must pull its cable followed by securing the retaining bolt while maintaining 10 Nm (100 kgf-cm, 7 kgf-cm) torque setting. When installing the throttle cable to the engine position the drain plug to 20 Nm (205 kgf-cm, 15 ft. lbs.). End the process by filling ATF and checking fluid level before performing throttle cable adjustment if needed.