×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Fuel Pressure Regulator

Fuel Tank Pressure Regulator- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

83 Fuel Pressure Regulators found

Toyota Fuel Pressure Regulator

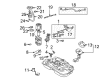

Part Number: 23280-38041$98.58 MSRP: $138.38You Save: $39.80 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Regulator Assembly, Fuel; Regulator Assembly, Fuel Pressure

- Replaces: 23280-38040

Toyota Fuel Pressure Regulator

Part Number: 23280-38051$98.58 MSRP: $138.38You Save: $39.80 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Regulator Assembly, Fuel; Fuel Injection Pressure Regulator; Pressure Regulator; Regulator Assembly, Fuel Pressure

- Replaces: 23280-38050

Toyota Fuel Pressure Regulator

Part Number: 23020-70010$127.95 MSRP: $181.12You Save: $53.17 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Regulator Assembly, Fuel; Fuel Injection Pressure Regulator; Pressure Regulator; Regulator Assembly, Fuel Pressure W/Jet Pump

Toyota Fuel Pressure Regulator

Part Number: 23280-20040$101.07 MSRP: $141.87You Save: $40.80 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Regulator Assembly, Fuel; Fuel Injection Pressure Regulator; Pressure Regulator; Regulator Assembly, Fuel Pressure

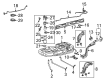

Toyota Damper Set, Fuel Pressure Pulsation

Part Number: 23207-20011$93.01 MSRP: $130.55You Save: $37.54 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: DAMPER SET, FUEL PRE; Fuel Pressure Damper; Fuel Pump Pulsator

- Replaces: 23207-46010, 23270-62010, 23270-62011, 23207-20010, 23207-74010

Toyota Fuel Pressure Regulator

Part Number: 23020-31010$98.82 MSRP: $138.70You Save: $39.88 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Regulator Assembly, Fuel; Fuel Injection Pressure Regulator; Pressure Regulator; Regulator Assembly, Fuel Pressure W/Jet Pump; Regulator Assembly, Fuel Pressure

Toyota Fuel Pressure Regulator

Part Number: 23280-38011$105.45 MSRP: $148.03You Save: $42.58 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Regulator Assembly, Fuel; Fuel Injection Pressure Regulator; Pressure Regulator; Regulator Assembly, Fuel Pressure

- Replaces: 23280-38010

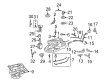

Toyota Fuel Pressure Regulator

Part Number: 23280-11070$98.09 MSRP: $137.69You Save: $39.60 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Regulator Assembly, Fuel; Fuel Injection Pressure Regulator; Pressure Regulator; Regulator Assembly, Fuel Pressure

Toyota Fuel Pressure Regulator

Part Number: 23280-15020$122.66 MSRP: $173.63You Save: $50.97 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Regulator Assembly, Fuel; Fuel Injection Pressure Regulator; Pressure Regulator; Regulator Assembly, Fuel Pressure

Toyota Fuel Pressure Regulator

Part Number: 23280-38091$98.58 MSRP: $138.38You Save: $39.80 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Regulator Assembly, Fuel; Fuel Injection Pressure Regulator; Pressure Regulator; Regulator Assembly, Fuel Pressure

- Replaces: 23280-38090

Toyota Fuel Pressure Regulator

Part Number: 23280-75110$121.72 MSRP: $172.31You Save: $50.59 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Regulator Assembly, Fuel; Regulator Assembly, Fuel Pressure

Toyota Fuel Pressure Regulator

Part Number: 23280-31051$105.45 MSRP: $148.03You Save: $42.58 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Regulator Assembly, Fuel; Fuel Injection Pressure Regulator; Pressure Regulator; Regulator Assembly, Fuel Pressure

- Replaces: 23280-31050

Toyota Fuel Pressure Regulator

Part Number: 23280-31060$108.53 MSRP: $152.34You Save: $43.81 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Regulator Assembly, Fuel; Fuel Injection Pressure Regulator; Pressure Regulator; Regulator Assembly, Fuel Pressure

Toyota Damper

Part Number: 23270-28070$143.28 MSRP: $202.82You Save: $59.54 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Damper Assembly, Fuel Pressure Pulsation; Fuel Pressure Damper

- Manufacturer Note: 2AZ-FE,*195

Toyota Fuel Pressure Regulator

Part Number: 23280-75061$143.10 MSRP: $202.58You Save: $59.48 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Regulator Assembly, Fuel; Regulator Assembly, Fuel Pressure

- Replaces: 23280-75060

Toyota Damper

Part Number: 23270-38021$111.14 MSRP: $156.01You Save: $44.87 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Damper Assembly, Fuel Pressure Pulsation; Fuel Pressure Damper

- Replaces: 23270-38020

Toyota Damper

Part Number: 23270-75050$111.38 MSRP: $156.34You Save: $44.96 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Damper Assembly, Fuel Pressure Pulsation; Fuel Pressure Damper

- Replaces: 23270-75010, 23270-75060

Toyota Fuel Pressure Regulator

Part Number: 23280-62020$97.37 MSRP: $136.68You Save: $39.31 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Regulator Assembly, Fuel; Fuel Injection Pressure Regulator; Pressure Regulator; Regulator Assembly, Fuel Pressure

- Product Specifications

- Other Name: Regulator Assembly, Fuel; Fuel Injection Pressure Regulator; Pressure Regulator; Regulator Assembly, Fuel Pressure

- Product Specifications

- Other Name: Regulator Assembly, Fuel; Fuel Injection Pressure Regulator; Pressure Regulator; Regulator Assembly, Fuel Pressure

| Page 1 of 5 |Next >

1-20 of 83 Results

Toyota Fuel Pressure Regulator

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Fuel Pressure Regulator? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

Toyota Fuel Pressure Regulator maintains a constant flow of fuel to deliver fewer jerks during the powering process and promote efficiency during all drives. By eliminating wastage, anyone on the line could stop the production line and correct the errors after which those lessons were replicated in leaner plants that produce long-lasting fuel miser cars that customers have faith in over the long term. The Hybrid Synergy Drive is cheered by Toyota drivers since the new system combines electric and gasoline endurance, thus the recent Prius plug-in and extended-range RAV4 plug-in accelerates lights and burns fuel, which is a perfect example of performance without a penalty on the environment. Toyota applied its TNGA to lower engines and harden chassis points and cut interior space, which translated into flatter cornering, smoother cabins and an impression that each model, including hatchback and SUV, has a single language of conversation. The Fuel Pressure Regulator is located in the fuel rail and consists of a spring-loaded diaphragm that trims the pump output to a constant target pressure with the vacuum signal or a return line discharging any surplus flow, thus maintaining the pressure at the same level when the engine is stopped in traffic or conquering a mountain pass. A broken Fuel Pressure Regulator may cause flooding of intake, dark exhaust, misfiring spark, slow acceleration and wasteful mileage since injectors may either flood or flow lean, hence it is better to detect rough idle or fuel dribble early on which will save power and money. Any Toyota wins with a healthy Fuel Pressure Regulator that dispenses the correct amount of fuel, making the brand name consisting of thrift and punch continue mile after mile.

Toyota Fuel Pressure Regulator Parts and Q&A

- Q: How to Service and Repair a Fuel Pressure Regulator on Toyota 4Runner?A:Before servicing the fuel pressure regulator the vacuum sensing hose and fuel return hose must be detached from it while using a container or shop towel to collect any escaping fuel. The two bolts attaching the fuel pressure regulator need removal with 8.0 Nm torque until both bolts reach 80 kg.cm or 69 in.lb before removing the O-ring. The installation of the pressure regulator requires a new gasket and the reassembly process should be performed in the reverse order of disassembly steps.

- Q: How to Service and Repair a Fuel Pressure Regulator on Toyota Tacoma?A:Service of the fuel pressure regulator starts by draining fuel system pressure and taking off the negative battery cable. The intake air connector requires removal alongside the No. 2 fuel hose disconnection. The procedure for removing the fuel pressure regulator begins by disconnecting three components including throttle with motor body connectors, VSV connector, and engine wire harness clamp. Begin by removing the bolt to detach the harness clamp bracket before proceeding to remove the three securing bolts connected to the fuel pressure regulator. The installer must apply a thin layer of gasoline or spindle oil to the O-ring then use the three bolts to mount the fuel pressure regulator with 8.5 N.m torque speed (87 kgf.cm, 75 in.lbf). Install the harness clamp bracket by bolting it in place with a torque of 8.2 N.m (84 kgf.cm, 73 in.lbf). Reestablish the attachment of the engine wire harness clamp together with the VSV connector and throttle with motor body connectors. Connect the No. 2 fuel hose while reinstalling the intake air connector and reestablish the cable connection to the negative battery terminal where torque should be 3.9 N.m (40 kgf.cm, 35 in.lbf). Finally, check for fuel leakage.

Related Toyota Parts

Browse Toyota Fuel Pressure Regulator by Models

Tacoma 4Runner Camry Tundra Corolla RAV4 Highlander Prius Sienna Land Cruiser Pickup FJ Cruiser 86 Sequoia T100 Avalon Celica Supra Yaris MR2 Matrix Solara Venza GR86 Echo C-HR Cressida Grand Highlander Paseo Previa Prius C Prius Prime Corolla Cross Corolla iM MR2 Spyder Prius V Starlet Tercel Van Yaris iA Prius Plug-In Prius AWD-e RAV4 Prime