×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Intake Manifold

Engine Intake Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

108 Intake Manifolds found

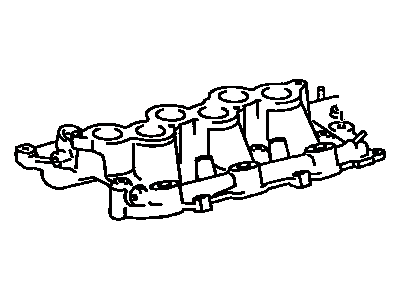

Toyota Intake Manifold

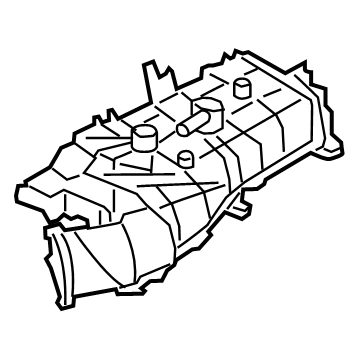

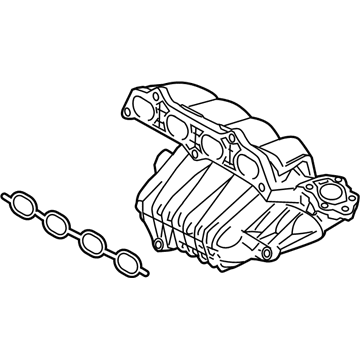

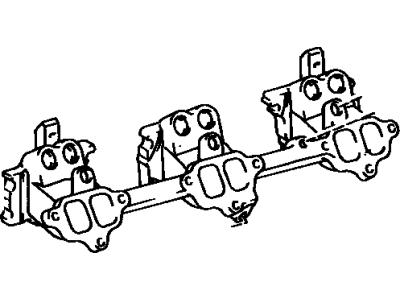

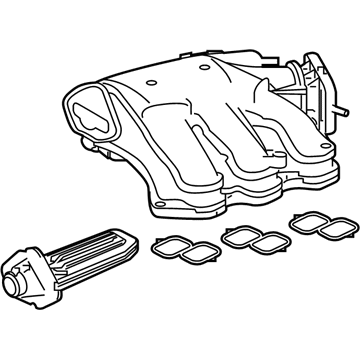

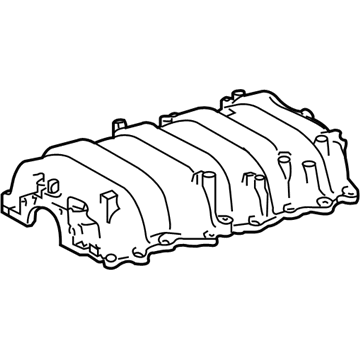

Part Number: 17101-WAA01$998.97 MSRP: $1464.00You Save: $465.03 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Sub-Assembly, Intake; Engine Intake Manifold; Manifold, Intake

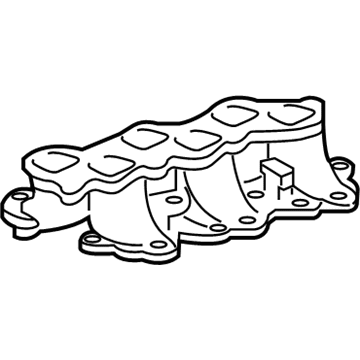

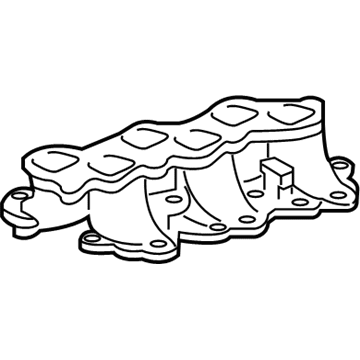

Toyota Manifold, Intake, Lower

Part Number: 17111-31141$398.49 MSRP: $583.99You Save: $185.50 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Intake Manifold

- Position: Lower

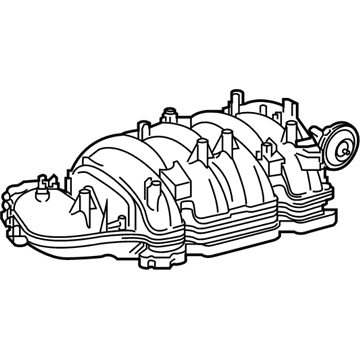

Toyota Manifold, Intake, Lower

Part Number: 17111-0P040$417.10 MSRP: $611.26You Save: $194.16 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Intake Manifold

- Manufacturer Note: (L)

- Position: Lower

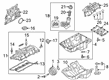

Toyota Intake Plenum

Part Number: 17109-31015$467.27 MSRP: $684.79You Save: $217.52 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Tank Sub-Assembly, Intake Air Surge

- Replaces: 17109-31010, 17109-31014, 17109-31011, 17109-31012

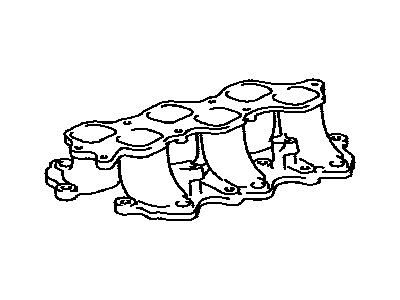

Toyota Intake Plenum

Part Number: 17190-0P061$752.91 MSRP: $1103.41You Save: $350.50 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Tank Assembly, Intake Air Surge

- Replaces: 17190-0P060

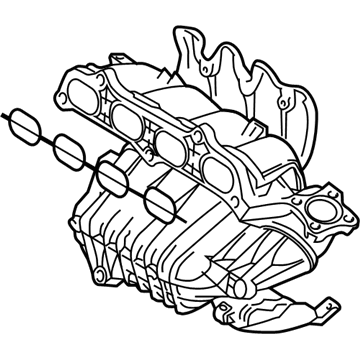

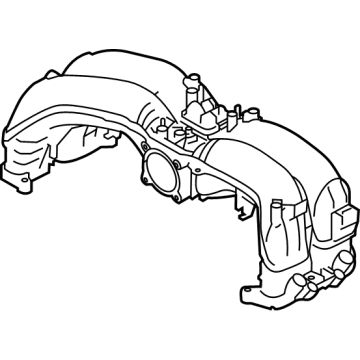

Toyota Intake Manifold

Part Number: 17120-28080$417.15 MSRP: $611.34You Save: $194.19 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Intake; Manifold, Intake

- Manufacturer Note: CALIFORNIA SPEC

Toyota Intake Manifold

Part Number: 17120-28041$452.17 MSRP: $662.67You Save: $210.50 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Intake

- Replaces: 17120-28040

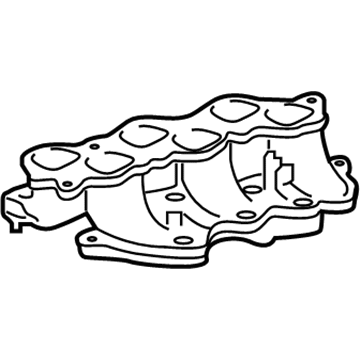

Toyota Manifold, Intake, Lower

Part Number: 17111-0P030$404.73 MSRP: $593.14You Save: $188.41 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Intake Manifold

- Position: Lower

Toyota Intake Manifold

Part Number: 17120-36021$776.10 MSRP: $1137.39You Save: $361.29 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Intake; Engine Intake Manifold; Manifold, Intake

- Replaces: 17120-36020

Toyota Intake Manifold

Part Number: 17120-0H050$444.34 MSRP: $651.19You Save: $206.85 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Intake; Engine Intake Manifold; Manifold, Intake

Toyota Intake Manifold, Lower

Part Number: 17111-31220$459.11 MSRP: $672.82You Save: $213.71 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold, Intake; Engine Intake Manifold, Lower

- Manufacturer Note: (J)

- Position: Lower

Toyota Manifold, Intake

Part Number: 17120-31070$441.05 MSRP: $646.37You Save: $205.32 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Intake; Intake Manifold

Toyota Intake Manifold

Part Number: 17101-WAA02$799.16 MSRP: $1171.19You Save: $372.03 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Sub-Assembly, Intake; Engine Intake Manifold; Manifold, Intake

- Product Specifications

- Other Name: MANIFOLD ASSY, INTAK; Manifold, Intake

- Replaced by: 17120-50020

Toyota Manifold, Intake

Part Number: 17101-66020$416.64 MSRP: $610.59You Save: $193.95 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Sub-Assembly, Intake; Intake Manifold

Toyota Manifold, Intake

Part Number: 17120-38033$1528.95 MSRP: $2240.69You Save: $711.74 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Intake; Intake Manifold

- Replaces: 17120-38031, 17120-38032, 17120-38030

Toyota Intake Manifold

Part Number: 17120-36030$824.34 MSRP: $1208.08You Save: $383.74 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Assembly, Intake; Manifold, Intake

- Manufacturer Note: *107

Toyota Intake Manifold

Part Number: 17190-31200$710.39 MSRP: $1041.08You Save: $330.69 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Tank Assembly, Intake Air Surge; Intake Plenum

- Replaces: 17190-31081

Toyota Intake Manifold

Part Number: SU003-09019$441.07 MSRP: $646.39You Save: $205.32 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold Complete-Intake; Engine Intake Manifold; Manifold, Intake

Toyota Manifold Sub-Assembly, Intake

Part Number: 17102-50041$481.57 MSRP: $705.74You Save: $224.17 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: MANIFOLD SUB-ASSY, I

- Replaces: 17102-50021

| Page 1 of 6 |Next >

1-20 of 108 Results

Toyota Intake Manifold

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Intake Manifold? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

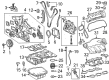

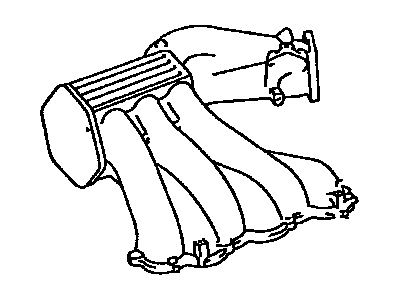

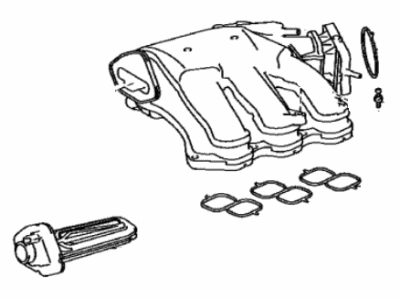

The Toyota Intake Manifold directs air at fresh air with accuracy to raise engine punch and throttle response. Toyota has evolved into an international giant of a company by cutting down on waste, empowering assembly lines, and being obsessed with real-world driving benefits. Toyota continues to introduce hybrids stretching to every gallon such as enhanced Prius Plug-in Hybrid models and an nearly all-electric SUV range that now goes to electric miles. Toyota stretched its TNGA platform to reduce centers of gravity, improve handling, and allow safety technology to be placed in more intelligent locations without overstated expense. Toyota gains long-lasting confidence due to engines that refuse to die, cabins that scorn decades, and ownership costs that are kept down to earth. The Intake Manifold, which is found inside the engine bay, is the traffic cop to airflow splitting the constant oxygen streams to each of the hungry cylinders. A new Intake Manifold crafted of plastic will save weight, resist heat soak, and mold in all runners such that each chamber receives an equal, high-velocity charge. Others are divided into upper and lower shells closed off with gaskets, with coolant passages within the Intake Manifold maintaining the temperatures. Variable length runners allow the Intake Manifold to adjust the speed of airflow to maintain torque high at low RPMs but increase power at high RPMs. Even distribution ensures that every cylinder burns its mixture evenly, enhancing efficiency and cutting off harmful emissions during loads. The mass is also shed off the nose by lightweight construction, making them turn in more quickly and slightly more economical.

Toyota Intake Manifold Parts and Q&A

- Q: How to remove and install Intake Manifold in Four cylinder engine on Toyota Highlander?A:To remove the intake manifold, first relieve the fuel system pressure and disconnect the cable from the negative battery terminal. Next, remove the air intake duct and resonator, followed by the cowl cover assembly. Then, take out the fuel rail and injectors as an assembly. For models from 1999 to 2007, remove the throttle linkage and throttle body from the intake manifold, label and detach the PCV and vacuum hoses connected to the intake manifold, and securely support the vehicle on jackstands. If working on a 4WD model, loosen the right side driveaxle/hub nut and the right front wheel lug nuts before raising the vehicle. Drain the transfer case lubricant, remove the right side driveaxle, and separate the transfer case mount from the transfer case, removing the transfer case mounting brace. For all models, work below the vehicle to remove the manifold lower mounting bolts, then from above, remove the intake manifold upper mounting nuts and bolts, and take out the manifold, gasket, and manifold insulator from the engine. For models from 2008 and later, remove the engine cover, disconnect the vacuum hoses and ventilation tubes from the intake manifold, and remove the throttle body with the electronic throttle actuator. Additionally, remove the windshield wiper motor, brake booster vacuum bracket, and outer cowl top assembly, then disconnect and remove the main harness connector to the intake manifold and tumble control valves. Apply battery voltage to the tumble control valve electrical connector to close the valve, preventing damage during removal. Remove the intake manifold support bracket and disconnect the vacuum switching valve assembly electrical connector, then unscrew the intake manifold mounting fasteners and remove the manifold. For installation, clean the mating surfaces of the intake manifold and cylinder head mounting surface, checking the gasket for leaks and the manifold for warpage. Press a new gasket into the grooves on the intake manifold, install the manifold and gasket over the studs on the cylinder head, and tighten the manifold-to-cylinder head nuts/bolts in three or four equal steps from the center outwards. Reinstall the remaining parts in reverse order, check the coolant level, refill the transfer case for 4WD models, and ensure the throttle linkage operates smoothly before starting the engine to check for coolant and vacuum leaks.

- Q: How to remove and install the intake manifold in V6 engine on 1995 through 2004 Toyota Tacoma?A:Before you make any move of pulling out the intake manifold, get a hold of your stereo's negative terminal then disconnect the battery to get beyond the anti theft system code if there is any. Pump out the coolant into a mixing bucket and then, remove the air cleaner assembly, the throttle body, the fuel injectors and the air intake plenum. It is also important to label all the remaining wires, hoses, and brackets connected to the intake manifold and the coolant outlets with new labels and remove them from the original bundle. Loosen and take off the intake manifold to engine bolts starting from the outside and going to the inside to make sure that the manifold is fully detached from both cylinder heads. Based on the above guidelines, if the manifold is stuck, do not use force and pry between gasket mating surfaces as this will damage them. For installation, scrape off the gasket material and sealant from the manifold and cylinder heads and then wash with lacquer thinner/acetone. New gaskets should be used and the manifold put on the engine; be certain the gaskets stay in position prior to putting the nuts or bolts; starting with the interior bolts and work towards the exterior. Slightly over torque the nuts or bolts in three or four operations, starting with exerting an equal amount of torque from the center in order to avoid distortion. Install the remaining components back in the reverse which it was removed, fill the cooling system and start the engine and check for any fuel or vacuum leakage or any leakage in the coolant.

Related Toyota Parts

Browse Toyota Intake Manifold by Models

Tacoma 4Runner Camry Tundra Corolla RAV4 Highlander Prius Sienna Land Cruiser Pickup FJ Cruiser 86 Sequoia T100 Avalon Celica Supra Yaris MR2 Matrix Solara Venza GR86 Echo C-HR Cressida Grand Highlander Paseo Previa Prius C Prius Prime Corolla Cross Corolla iM Crown GR Corolla MR2 Spyder Prius V Tercel Yaris iA Prius Plug-In GR Supra Prius AWD-e RAV4 Prime