×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota RAV4 Intake Manifold

Engine Intake Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Intake Manifolds found

Toyota RAV4 Intake Manifold

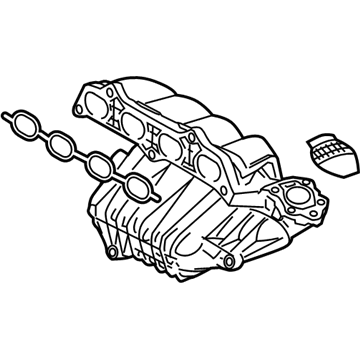

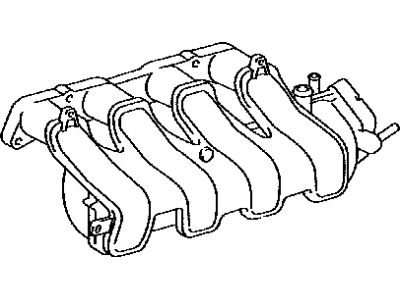

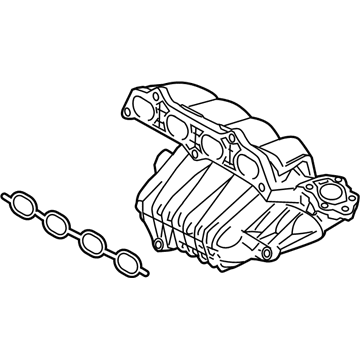

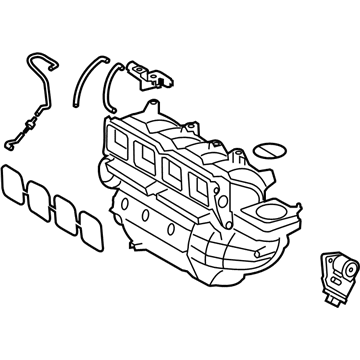

Part Number: 17120-F0010$372.50 MSRP: $545.89You Save: $173.39 (32%)Ships in 1-3 Business DaysToyota RAV4 Intake Manifold

Part Number: 17120-28101$323.28 MSRP: $461.56You Save: $138.28 (30%)Ships in 1-3 Business DaysToyota RAV4 Intake Manifold

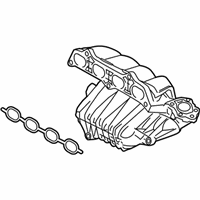

Part Number: 17120-28051$334.93 MSRP: $478.19You Save: $143.26 (30%)Ships in 1-3 Business DaysToyota RAV4 Manifold, Intake

Part Number: 17120-F0060$372.50 MSRP: $545.89You Save: $173.39 (32%)Ships in 1-3 Business DaysToyota RAV4 Intake Manifold

Part Number: 17120-F0020$372.50 MSRP: $545.89You Save: $173.39 (32%)Ships in 1-2 Business DaysToyota RAV4 Intake Manifold

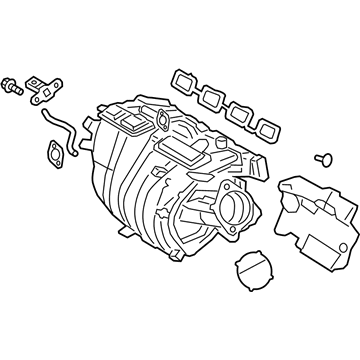

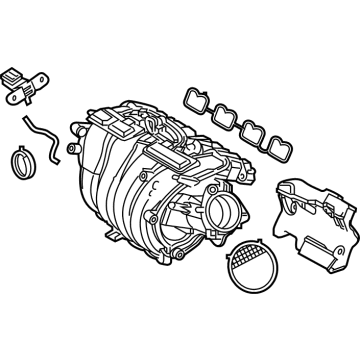

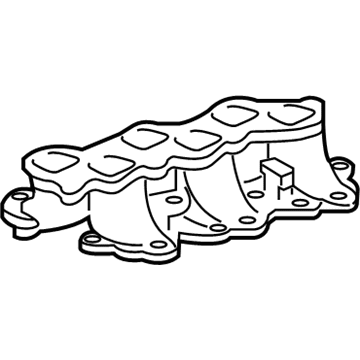

Part Number: 17120-36021$776.10 MSRP: $1137.39You Save: $361.29 (32%)Ships in 1-3 Business DaysToyota RAV4 Manifold, Intake, Lower

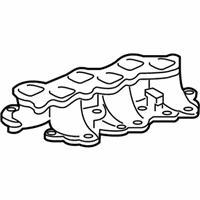

Part Number: 17111-31141$398.49 MSRP: $583.99You Save: $185.50 (32%)Ships in 1-3 Business DaysToyota RAV4 Intake Manifold

Part Number: 17120-36050$337.72 MSRP: $482.19You Save: $144.47 (30%)Ships in 1-3 Business Days

Toyota RAV4 Intake Manifold

Choose genuine Intake Manifold that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Intake Manifold for your Toyota RAV4? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota RAV4 parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota RAV4 Intake Manifold Parts and Q&A

- Q: How to install the intake manifold on Toyota RAV4?A:The first task for installing the 2AR-FE engine intake manifold involves fitting the intake air control valve actuator for the TCV. The clamp installation on the intake manifold should be followed by the purge line hose connection at the clamp interface. You should install the wiring harness clamp bracket through a bolt application at 10 Nm (102 kgf-cm, 7 ft-lbf) torque. The check valve installation requires two vacuum hoses to connect to the intake manifold as per the installation checklist. The installer must attach the connector tube hose with union to the intake manifold. The tumble control valves should stay closed during intake manifold installation to avoid damage while both the manifold and the gasoline tank parts must be assembled using 6 bolts at 21 Nm (214 kgf-cm, 15 ft-lbf). After connecting the No. 2 ventilation hose to the intake manifold you must proceed with the fuel delivery pipe sub-assembly installation. Secure the vacuum switching valve assembly for ACIS with a bolt to a torque of 9.0 Nm (92 kgf-cm, 80 in-lbf) while attaching the 2 vacuum hoses and union to connector tube hose. You should clamp and connect the wire harness before installing the bracket with a bolt tightened to 10 Nm (102 kgf-cm, 7 ft-lbf). Then attach the intake air control actuator connector before securing the wire harness with bolts and clamps. Use 2 bolts to join the 2 wire harness brackets at 10 Nm (102 kgf-cm, 7 ft-lbf). Each bolt should achieve this torque. After which, connect the 2 connectors along with their 4 injector connectors. After assembly of the fuel tube sub-assembly and Throttle Body assembly and air cleaner cap sub-assembly one should proceed with installation. First attach the outlet heater water hose to both the by-pass pipe and heater radiator unit followed by the inlet heater water hose connection to the cylinder head and heater radiator unit. The hose requires installation through the hose tube using two nuts tightened to 5.4 Nm (55 kgf-cm, 48 in-lbf) before attaching the hose. Secure the tube end of connector tube hose to the tube using the union component. Fasten the cowl top outer panel sub-assembly using 14 bolts which need tightening to a torque of 7.0 Nm (71 kgf-cm, 62 in-lbf) followed by attaching 3 clamps. The cowl ventilator housing sub-assembly requires four clamps for installation before installing the front Wiper Motor and link. To complete the procedure, attach the cable to the negative battery terminal, add engine coolant and inspect for coolant and fuel leaks before installing the No. 1 engine under cover and No. 1 engine cover sub-assembly.

- Q: How to remove the intake manifold on Toyota RAV4?A:Before starting the process for removing the intake manifold on 2AR-FE engines, operators should discharge fuel system pressure initially. The first step involves taking off the engine under cover at position No. 1 before emptying the engine coolant. The battery cable needs disconnection from the negative terminal while remaining without power for at least 90 seconds to deactivate the SRS system. The front Wiper Motor with link must be disassembled before removing the cowl ventilator housing through its 4 clamps. Unscrew the three clamps followed by disconnecting the wire harness to pull off the cowl top outer panel which requires disconnecting the union to connector tube hose. Remove the two tube nuts while disconnecting the hose before detaching both heater radiator unit and cylinder head inlet and outlet heater hoses. The procedure consists of removing the No. 1 engine cover sub-assembly together with the air cleaner cap sub-assembly along with the Throttle Body assembly. Vehicle maintenance requires disconnecting the fuel tube sub-assembly along with the wire harness through disconnecting the 4 injector connectors and 2 other connectors followed by removing the 2 bolts and brackets. Connect the battery voltage to the connector terminals for 1 to 3 seconds which should not exceed 3 seconds to prevent damage to the tumble control valves. You need to remove the bolt before you detach the 2 clamps from the intake manifold and bracket along with disconnecting the intake air control valve actuator connector and detaching the clamp with wire harness. The ACIS maintenance process involves removing the vacuum switching valve assembly after disconnecting both vacuum hoses and the union to connector tube hose with the help of a bolt. Remove the No. 2 ventilation hose from the intake manifold before removing its 6 bolts while keeping valves in the closed position. First disconnect both vacuum hoses from the check valve and intake manifold positions followed by gasket removal from the intake manifold and unhooking the hose connecting the union to the connector tube. First disconnect the wiring harness clamp bracket then remove the purge line hose from the clamp followed by removing the clamp from the intake manifold.