×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota RAV4 Brake Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

27 Brake Master Cylinders found

Toyota RAV4 Master Cylinder

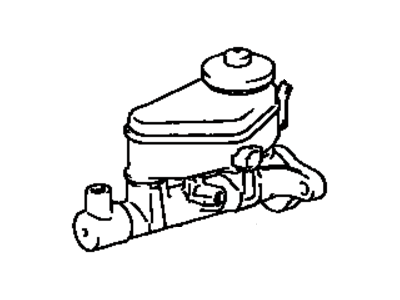

Part Number: 47201-42270$277.35 MSRP: $395.99You Save: $118.64 (30%)Ships in 1-3 Business Days

Toyota RAV4 Master Cylinder

Part Number: 47201-42260$288.68 MSRP: $412.16You Save: $123.48 (30%)Ships in 1 Business Day

Toyota RAV4 Master Cylinder

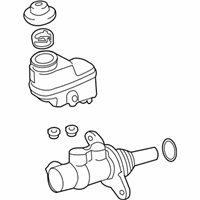

Part Number: 47201-0R082$184.87 MSRP: $263.96You Save: $79.09 (30%)Ships in 1-3 Business DaysToyota RAV4 Master Cylinder

Part Number: 47055-0R010$902.77 MSRP: $1323.01You Save: $420.24 (32%)Ships in 1-3 Business DaysToyota RAV4 Master Cylinder

Part Number: 47201-42231$223.16 MSRP: $318.61You Save: $95.45 (30%)Ships in 1-3 Business DaysToyota RAV4 Master Cylinder

Part Number: 47201-42091$185.62 MSRP: $265.02You Save: $79.40 (30%)Ships in 1-3 Business DaysToyota RAV4 Master Cylinder

Part Number: 47201-42241$232.76 MSRP: $332.32You Save: $99.56 (30%)Ships in 1-3 Business DaysToyota RAV4 Master Cylinder

Part Number: 47201-0R070$203.28 MSRP: $290.24You Save: $86.96 (30%)Ships in 1-3 Business DaysToyota RAV4 Master Cylinder

Part Number: 47201-42240$194.28 MSRP: $277.38You Save: $83.10 (30%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 27 Results

Toyota RAV4 Brake Master Cylinder

Choose genuine Brake Master Cylinder that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Brake Master Cylinder for your Toyota RAV4? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota RAV4 parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota RAV4 Brake Master Cylinder Parts and Q&A

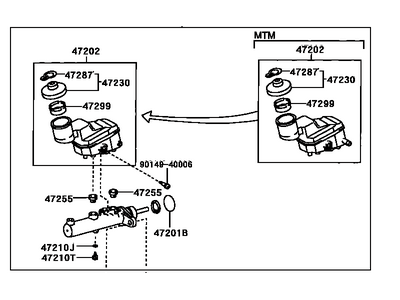

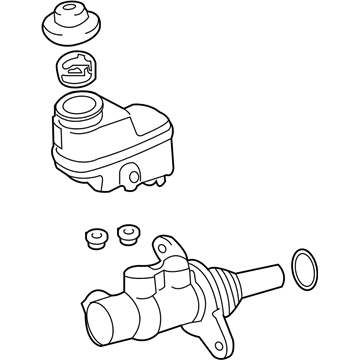

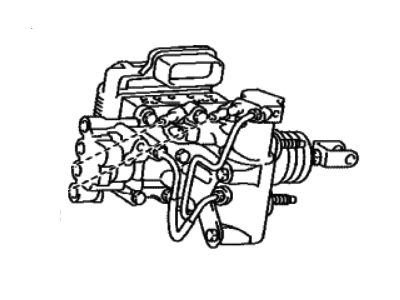

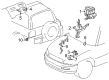

- Q: How to install the brake master cylinder on Toyota RAV4?A:The installation process for the brake master cylinder starts by keeping the tip of the master cylinder oriented downward to avoid piston loss while cleaning the piston before applying lithium soap base glycol grease to its outer circumference contact surfaces. Attach the master cylinder to the booster with two nuts where the torque should be set at 12.5 Nm (127 kgf-cm, 9 ft-lbf). Insert and torque the two Brake Lines designated B to the master cylinder by utilizing Special Service Tool: 09023-00101 with torques at 15.2 Nm (155 kgf-cm, 11 ft-lbf) and 14 Nm (144 kgf-cm, 10 ft-lbf) delivered by a torque wrench with a 30 cm (11.81 in.) fulcrum length. The master cylinder receives connector A from the brake fluid level warning switch then the fluid reservoir is filled before air bleeds out of the brake master cylinder along with the brake lines and ABS and traction actuator assembly. Inspection of the brake fluid reservoir and search for any brake fluid leaks is necessary. The installation requires proper methods to place the air cleaner case sub-assembly for 2AZ-FE or the air cleaner case for 2GR-FE.

- Q: How to remove the brake master cylinder while ensuring the piston does not fall out on Toyota RAV4?A:When removing the brake master cylinder keep the piston tip pointed downward to avoid its fall out from the device. Use a cloth to clear attached foreign objects on the piston then treat its whole outer surface area with lithium soap base glycol grease. Start the procedure by taking out the air cleaner case sub-assemblies that belong to either the 2AZ-FE or the 2GR-FE platform using proper protocols for each system. The brake fluid requires draining while washing off any dripping fluid exposed to painted components. End engine operation and press the brake pedal repeatedly to empty the Brake Booster vacuum pressure. First remove connector A from the brake fluid warning switch and utilize tool Special Service Tool: 09023-00101 to disconnect Brake Lines B from the master cylinder. Remove the two nuts while pulling out the master cylinder from the brake booster but keep the piston in its current position. The O-ring from the master cylinder should be removed as the final step.