×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Matrix Brake Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Brake Master Cylinders found

Toyota Matrix Master Cylinder

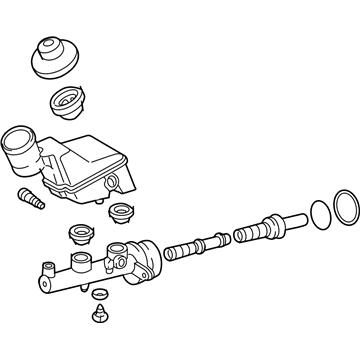

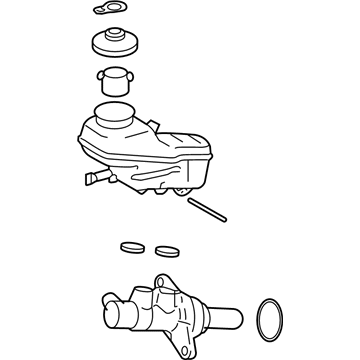

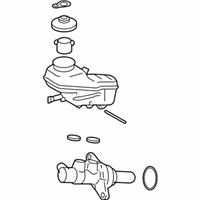

Part Number: 47201-02320$230.08 MSRP: $328.49You Save: $98.41 (30%)Ships in 1-3 Business DaysToyota Matrix Master Cylinder

Part Number: 47201-02593$254.07 MSRP: $362.76You Save: $108.69 (30%)Ships in 1-3 Business DaysToyota Matrix Master Cylinder

Part Number: 47201-02491$203.63 MSRP: $290.73You Save: $87.10 (30%)Ships in 1-3 Business DaysToyota Matrix Master Cylinder

Part Number: 47201-02483$273.65 MSRP: $390.71You Save: $117.06 (30%)Ships in 1-3 Business DaysToyota Matrix Master Cylinder

Part Number: 47201-02340$293.29 MSRP: $418.75You Save: $125.46 (30%)Ships in 1-3 Business DaysToyota Matrix Master Cylinder

Part Number: 47201-02310$227.75 MSRP: $325.18You Save: $97.43 (30%)Ships in 1-3 Business DaysToyota Matrix Master Cylinder

Part Number: 47201-02300$230.08 MSRP: $328.49You Save: $98.41 (30%)Ships in 1-3 Business DaysToyota Matrix Master Cylinder

Part Number: 47201-02290$221.11 MSRP: $315.69You Save: $94.58 (30%)Ships in 1-3 Business Days

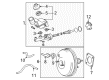

Toyota Matrix Brake Master Cylinder

Choose genuine Brake Master Cylinder that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Brake Master Cylinder for your Toyota Matrix? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Matrix parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Matrix Brake Master Cylinder Parts and Q&A

- Q: How to install the brake master cylinder on Toyota Matrix?A:The brake master cylinder installation starts with installing the master cylinder sub-assembly and No. 1 way which require the valve bracket to be fastened with 2 nuts tightened to 12.5 Nm (127 kgf-cm, 9 ft-lbf). Special Service Tool: 09023-00101 helps connect the 2 or 3 brake tubes to the No. 1 way through application of 15 Nm (155 kgf-cm, 11 ft-lbf) torque. Use the identical torque value to join the master cylinder sub-assembly and the two brake tubes. The clutch reservoir tube (No.1) requires connection with its clip to the master cylinder reservoir sub-assembly while also attaching the brake fluid level switch connector there in manual transmission vehicles. When the air cleaner cap sub-assembly is in place, it is necessary to fill the reservoir with brake fluid. Special Service Tool: 09023-00101 should be used to bleed the master cylinder before performing Brake Line bleeding. Check both the brake fluid exactly at the reservoir and look for fluid leaks throughout the system.

- Q: How to remove and replace the brake master cylinder on Toyota Matrix?A:The brake master cylinder requires removal with a process that starts with inspecting and adjusting the Brake Booster push rod before replacement. Fasten the brake tube way sub-assembly with 2 nuts to the brake booster assembly while torquing them to 13 Nm (132 kgf-cm, 10 ft-lbf). Proper handling of the master cylinder must be maintained since impacts could occur when placing it with the piston positioned upward to prevent piston escape. A clean cloth should be used to remove foreign matter from the piston before applying an even layer of lithium soap base glycol grease which must cover the entire piston circumference. Use a union nut wrench (10 mm) to connect the Brake Lines to the master cylinder assembly while torquing this way (15 Nm without wrench and 14 Nm with wrench) when maintaining a torque wrench fulcrum length of 250 mm (9.84 in.) which stays parallel to the nut. After connecting the clamp you should join the connector to the brake master cylinder reservoir assembly with a clip. Fill the reservoir with brake fluid followed by bleeding the clutch line for C59 and E351 then bleeding the brake master cylinder before bleeding the brake line and finally bleeding the brake actuator with VSC. Brake fluid leaks must be evaluated while checking the fluid level in the reservoir. Both 2ZR-FE and 2AZ-FE engine installations require the air cleaner case and cap sub-assembly followed by installing the No. 2 then No. 1 cylinder head covers based on engine type. Install the suspension tower damper assembly together with the front strut bar then install the outer cowl top panel using 12 bolts torqued to 8.8 Nm (90 kgf-cm, 78 in-lbf). After that, engage the clamp before bending the water guard plate RH to fit inside the clamp. After finishing install the windshield Wiper Motor and link assembly and both cowl top ventilator louvers as well as hood to cowl top seal and front wiper arm and blade assemblies and their associated head caps.