×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Camry Wheel Bearing

Hub Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

32 Wheel Bearings found

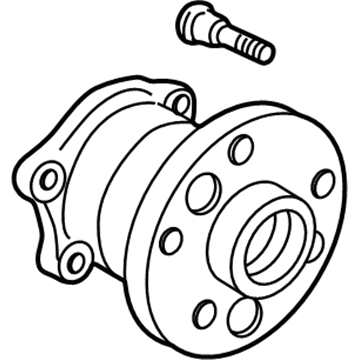

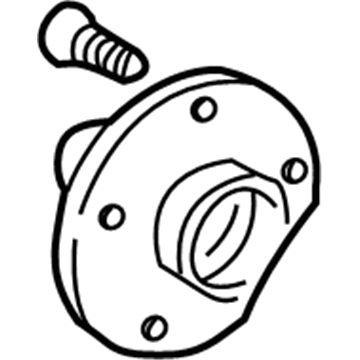

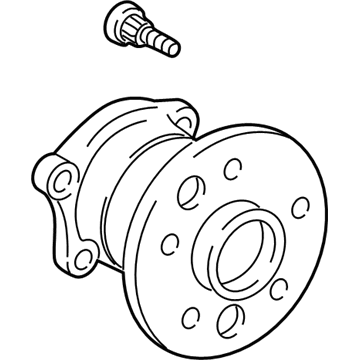

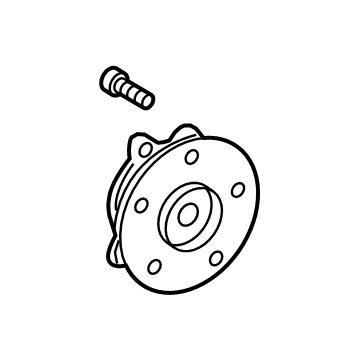

Toyota Camry Hub & Bearing Assembly, Rear Axle, Passenger Side

Part Number: 42450-33020$401.67 MSRP: $588.65You Save: $186.98 (32%)Ships in 1-3 Business Days

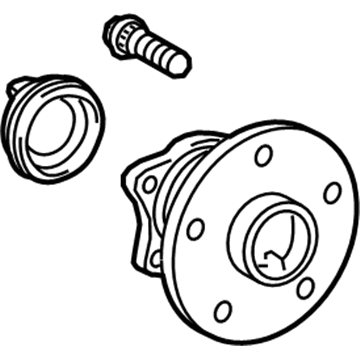

Toyota Camry Hub Assembly, Rear

Part Number: 42450-33080$341.85 MSRP: $500.99You Save: $159.14 (32%)Ships in 1-2 Business Days

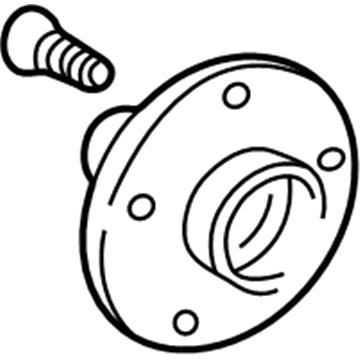

Toyota Camry Front Hub

Part Number: 43502-32070$174.85 MSRP: $249.65You Save: $74.80 (30%)Ships in 1-3 Business Days

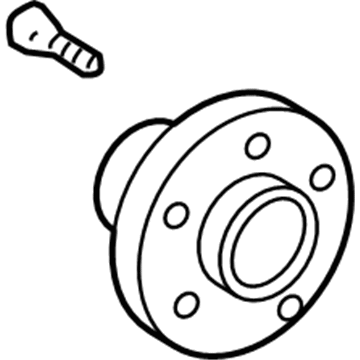

Toyota Camry Hub Assembly, Front

Part Number: 43502-0E030$130.65 MSRP: $184.95You Save: $54.30 (30%)

Toyota Camry Front Hub

Part Number: 43502-42020$153.44 MSRP: $217.21You Save: $63.77 (30%)Ships in 1-2 Business DaysToyota Camry Hub & Bearing Assembly, Rear Axle, Passenger Side

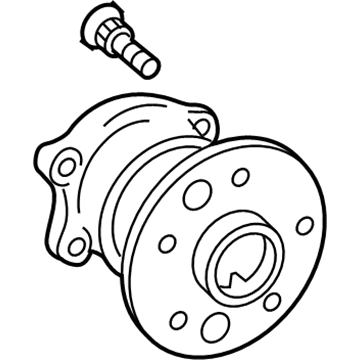

Part Number: 42450-33010$401.67 MSRP: $588.65You Save: $186.98 (32%)Ships in 1-3 Business DaysToyota Camry Hub Assembly

Part Number: 42410-33050$395.88 MSRP: $580.16You Save: $184.28 (32%)Ships in 1-3 Business DaysToyota Camry Hub Assembly

Part Number: 42410-33060$376.81 MSRP: $552.21You Save: $175.40 (32%)Ships in 1-3 Business DaysToyota Camry Hub Assembly

Part Number: 42410-33040$415.97 MSRP: $609.60You Save: $193.63 (32%)Ships in 1-3 Business DaysToyota Camry Bearing Housing, Rear

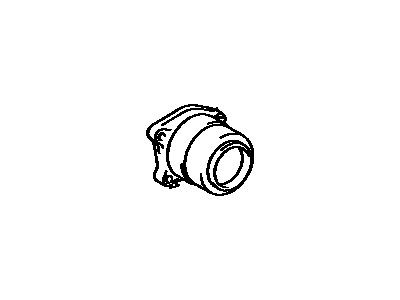

Part Number: 42409-20010$252.62 MSRP: $360.68You Save: $108.06 (30%)Ships in 1-3 Business DaysToyota Camry Rear Wheel Bearing

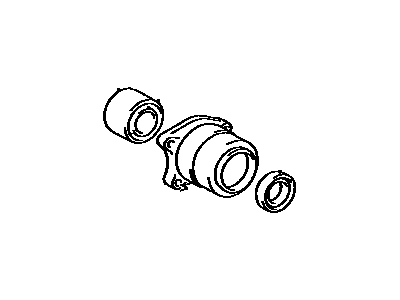

Part Number: 42409-33020$297.86 MSRP: $425.27You Save: $127.41 (30%)Ships in 1-3 Business DaysToyota Camry Inner Shaft Bearing, Front

Part Number: 90369-36001-77$46.22 MSRP: $64.33You Save: $18.11 (29%)Ships in 1-3 Business Days

Toyota Camry Hub Sub-Assembly, Front Axle, Passenger Side

Part Number: 43502-06040$162.49 MSRP: $230.03You Save: $67.54 (30%)

Toyota Camry Hub Assembly, Front

Part Number: 43550-06050$270.50 MSRP: $386.22You Save: $115.72 (30%)

| Page 1 of 2 |Next >

1-20 of 32 Results

Toyota Camry Wheel Bearing

Choose genuine Wheel Bearing that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Wheel Bearing for your Toyota Camry? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Camry parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

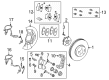

One of the critical parts for the vehicle is the Toyota Camry Wheel Bearing considered as the key element towards reliability and performance inherent to Toyota vehicles. Intended to hold the wheel and allow easy rotation, the Camry wheel bearing minimizes the drag, thus raising the vehicle's performance level. This integral part is suitable for the different models of the Toyota Camry brand that started in 1982 and has gone through up to the twelfth generation, including the current 11th generation. In ways, the wheel bearing of the Toyota Camry also needs regular maintenance because when the bearing is ignored, it can lead to several problems like the uneven wearing of the tires, a grinding sound during turns and sometimes vibrations in the steering column; all of which can impair the car's safety and the driver's control. Due to the effect a faulty wheel bearing has on a vehicle, regular check up and replacement is crucial for proper use of the vehicle. The Toyota Camry wheel bearing is unique in the automotive market by their strong construction and convenient installation into the vehicle and the drive train to properly operate the wheels. This reliability not only adds the comfort in the driving experience but also boosts on the safety of the car. It is worthy to note that the wheel bearing of the Toyota Camry has been known to last longer and perform better, which has attributed to the reason why Toyota has stood out as one of the premier car manufacturers that any driver would want to be associated with due to efficiency and safety in automobile. Therefore, the Toyota Camry wheel bearing has a central role in the durability and efficiency of the Toyota Camry, which in turn affirms the car's reliability.

Toyota Camry Wheel Bearing Parts and Q&A

- Q: How to install the rear axle hub and Wheel Bearing assembly on Toyota Camry?A:The installation of the rear axle hub and bearing assembly requires a proper fitting of its 4 bolts at 80 Nm (816 kgf-cm, 59 ft-lbf) torque specification. The installation requires connecting the skid control sensor connector properly without twisting the sensor wire. The installation process requires a thorough examination of the rear axle hub bearing for any sign of looseness and measurement of the rear axle hub runout. Install the rear disc and the fitting of rear disc Brake Caliper assembly next. You should put the rear wheel in place before applying torque of 103 Nm (1,050 kgf-cm, 76 ft-lbf). Connect the skid control sensor connector while also verifying the ABS speed sensor signal function.

- Q: How to remove the rear axle hub and Wheel Bearing assembly on Toyota Camry?A:The first step to remove the rear axle hub and bearing assembly starts with taking away the rear wheel. Move on to separate the rear braking caliper assembly from the rear disc brake. First you must take off the rear disc and then the procedure can continue. The necessary first step is to disconnect the skid control sensor connector followed by hub and bearing assembly removal through two connector disconnections and four bolt removal sequence.