×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Camry Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

63 Brake Lines found

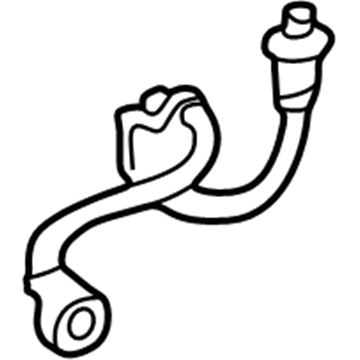

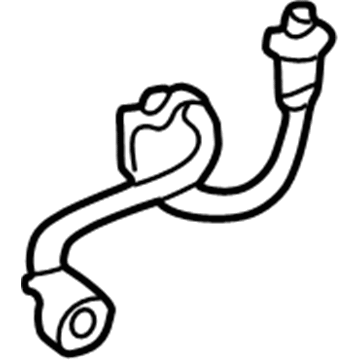

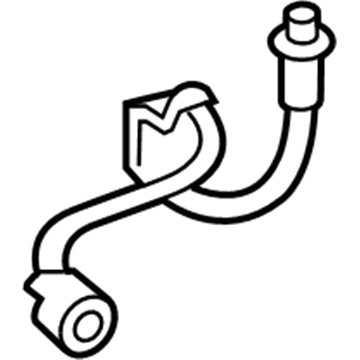

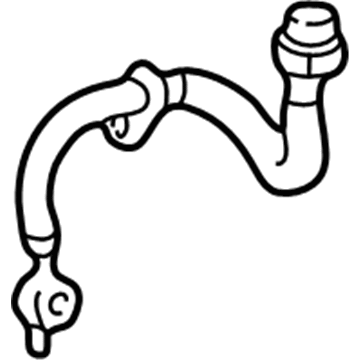

Toyota Camry Hose, Flexible(For Front), Passenger Side

Part Number: 90947-02F58$81.87 MSRP: $114.92You Save: $33.05 (29%)Ships in 1-3 Business Days

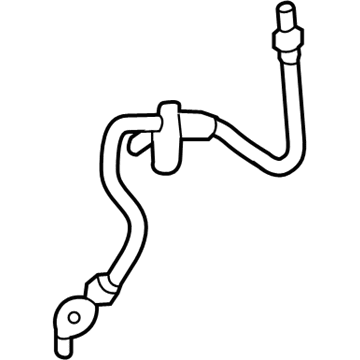

Toyota Camry Flex Hose, Driver Side

Part Number: 90947-02F59$81.87 MSRP: $114.92You Save: $33.05 (29%)Ships in 1-3 Business DaysToyota Camry Flex Hose

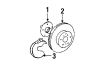

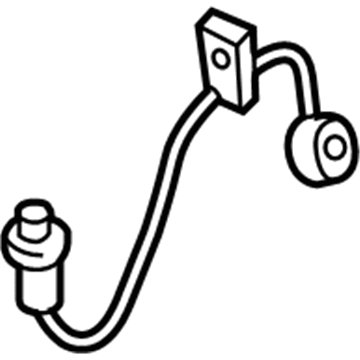

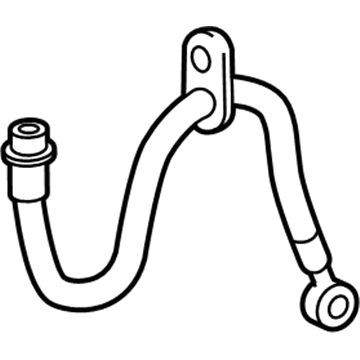

Part Number: 90947-02429$65.57 MSRP: $92.03You Save: $26.46 (29%)Ships in 1-3 Business DaysToyota Camry Flex Hose, Rear Driver Side

Part Number: 90080-94036$76.18 MSRP: $106.94You Save: $30.76 (29%)Ships in 1-3 Business DaysToyota Camry Flex Hose, Passenger Side

Part Number: 90080-94096$67.18 MSRP: $94.30You Save: $27.12 (29%)Ships in 1-3 Business DaysToyota Camry Hose, Flexible(For Rear Passenger Side)

Part Number: 90947-02750$76.12 MSRP: $106.86You Save: $30.74 (29%)Ships in 1-3 Business DaysToyota Camry Flex Hose, Driver Side

Part Number: 90947-02876$93.48 MSRP: $131.22You Save: $37.74 (29%)Ships in 1-3 Business DaysToyota Camry Flex Hose, Rear Driver Side

Part Number: 90947-A2018$113.39 MSRP: $159.17You Save: $45.78 (29%)Ships in 1-3 Business DaysToyota Camry Flex Hose

Part Number: 90947-02987$78.01 MSRP: $109.50You Save: $31.49 (29%)Ships in 1-3 Business DaysToyota Camry Flex Hose, Rear Driver Side

Part Number: 90080-94097$67.18 MSRP: $94.30You Save: $27.12 (29%)Ships in 1-3 Business DaysToyota Camry Flex Hose, Passenger Side

Part Number: 90080-94035$76.18 MSRP: $106.94You Save: $30.76 (29%)Ships in 1-3 Business DaysToyota Camry Flex Hose, Driver Side

Part Number: 90080-94198$90.95 MSRP: $127.66You Save: $36.71 (29%)Ships in 1-3 Business DaysToyota Camry Hose, Flexible(For Rear Driver Side)

Part Number: 90947-02F61$92.77 MSRP: $130.23You Save: $37.46 (29%)Ships in 1-3 Business DaysToyota Camry Hose, Flexible(For Front), Passenger Side

Part Number: 90947-02875$93.48 MSRP: $131.22You Save: $37.74 (29%)Ships in 1 Business DayToyota Camry Flex Hose, Rear Driver Side

Part Number: 90080-94020$75.82 MSRP: $106.42You Save: $30.60 (29%)Ships in 1-3 Business DaysToyota Camry Flex Hose, Rear Driver Side

Part Number: 90947-A2060$81.16 MSRP: $113.92You Save: $32.76 (29%)Ships in 1-3 Business DaysToyota Camry Flex Hose, Passenger Side

Part Number: 90947-02F60$92.77 MSRP: $130.23You Save: $37.46 (29%)Ships in 1-3 Business DaysToyota Camry Flex Hose, Passenger Side

Part Number: 90080-94197$90.95 MSRP: $127.66You Save: $36.71 (29%)Ships in 1-3 Business DaysToyota Camry Flex Hose, Passenger Side

Part Number: 90080-94094$94.27 MSRP: $132.31You Save: $38.04 (29%)Ships in 1-3 Business DaysToyota Camry Flex Hose, Driver Side

Part Number: 90947-A2012$110.07 MSRP: $154.51You Save: $44.44 (29%)Ships in 1-3 Business Days

| Page 1 of 4 |Next >

1-20 of 63 Results

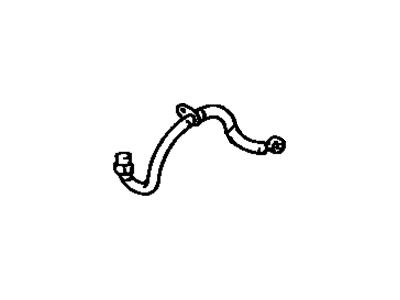

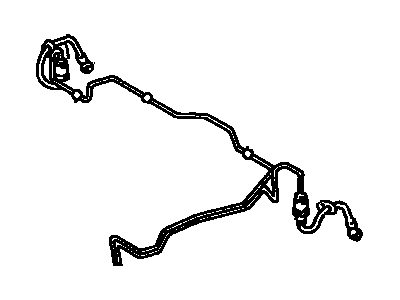

Toyota Camry Brake Line

Choose genuine Brake Line that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Brake Line for your Toyota Camry? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Camry parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

The Toyota Camry Brake Line which is hydraulic is an essential part that passes brake fluid from the master cylinder to the brake caliper pistons. As a result of pressure and friction, Brake Line assists in controlling and stopping the wheel of the car. metal/rubber-producing; the lines have to be regularly inspected so as to ensure there are no leaks, this is in order to offer the optimal braking system. Sometimes failure to maintain the condition of the Brake Line results in brake failure thus the safety of the vehicle is at risk. Some problems like brake tube perforation have been noted on some models of the year 2010, therefore there is a need to have regular check ups on the brake line Toyota Camry.

Toyota Camry Brake Line Parts and Q&A

- Q: How to remove the rear Brake Line on Toyota Camry?A:A proper brake fluid drain followed by rear wheel removal enables access to remove the rear brake flexible hose. The removal sequence for the rear brake flexible hose begins with bolted removal of union and hose along with gasket extraction. Before proceeding one must remove the bolt to detach the rear brake flexible hose. Special Service Tool: 09023-00101 allows users to safely remove the brake line by retaining the rear brake flexible hose under wrench pressure during the procedure. At all contact points the user should avoid line bending or breakage and foreign material including dust and dirt should be stopped from entering the tube structure. Finally, remove the clip.

- Q: How to install the front Brake Line on Toyota Camry?A:The installation process for the front brake flexible hose requires connecting it with the union bolt and new gasket before torquing it to 29 Nm (300 kgf-cm, 21ft-lbf). Secure the Shock Absorber by placing the front flexible hose and Speed Sensor onto it with a bolt that needs a torque of 19 Nm (194 kgf-cm, 14ft-lbf). Install the bracket toward the vehicle exterior. The brake tube requires connection to the front brake flexible hose using Special Service Tool: 09023-00101 and wrench usage for holding the hose. When not using the tool apply 15 Nm (155 kgf-cm, 11ft-lbf) torque and with the tool use a 14 Nm (143 kgf-cm, 10ft-lbf) torque. During connection of brake tube keep it from getting bent and avoid foreign substances from entering the tube at both points. A torque wrench with 250 mm (9.84 in.) fulcrum length should be used when applying torque keeping the wrench in a parallel position for proper accuracy. The front brake flexible hose installation requires a new clip to be fitted correctly with its identification mark facing outward and its rotation minimized before pushing the clip to its maximum extent possible. The brake fluid should be added to the reservoir followed by bleeding the master cylinder and brake line with additional steps involving bleeder of the brake actuator assembly for TMC Made with VSC. Before installing the front wheel it is important to check the brake fluid level in the reservoir and inspect for brake fluid leaks before applying torque of 103 Nm (1,050 kgf-cm, 76ft-lbf).