×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

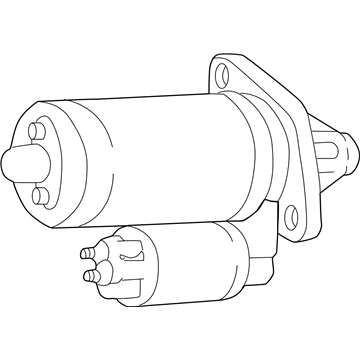

OEM Toyota 4Runner Starter Motor

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

21 Starter motors found

Toyota 4Runner Starter

Part Number: 28100-50090-84$167.82 MSRP: $236.25You Save: $68.43 (29%)Ships in 1-3 Business Days

Toyota 4Runner Starter

Part Number: 28100-31050-84$154.48 MSRP: $217.33You Save: $62.85 (29%)Ships in 1-3 Business Days

Toyota 4Runner Starter

Part Number: 28100-50100-84$117.39 MSRP: $163.33You Save: $45.94 (29%)Ships in 1-3 Business Days

Toyota 4Runner Starter

Part Number: 28100-34080-84$70.20 MSRP: $96.96You Save: $26.76 (28%)Ships in 1-3 Business Days

Toyota 4Runner Starter

Part Number: 28100-35060-84$118.44 MSRP: $164.82You Save: $46.38 (29%)Ships in 1-3 Business DaysToyota 4Runner Starter

Part Number: 28100-65100-84$169.90 MSRP: $239.20You Save: $69.30 (29%)Ships in 1-3 Business DaysToyota 4Runner Starter

Part Number: 28100-75110-84$166.45 MSRP: $234.32You Save: $67.87 (29%)Ships in 1-3 Business DaysToyota 4Runner Starter

Part Number: 28100-75090-84$166.45 MSRP: $234.32You Save: $67.87 (29%)Ships in 1-3 Business DaysToyota 4Runner Starter

Part Number: 28100-62050-84$160.08 MSRP: $225.28You Save: $65.20 (29%)Ships in 1-3 Business DaysToyota 4Runner Starter

Part Number: 28100-65090-84$151.75 MSRP: $213.46You Save: $61.71 (29%)Ships in 1-3 Business DaysToyota 4Runner Starter

Part Number: 28100-65030-84$151.75 MSRP: $213.46You Save: $61.71 (29%)Ships in 1-3 Business DaysToyota 4Runner Starter

Part Number: 28100-75120-84$150.67 MSRP: $211.93You Save: $61.26 (29%)Ships in 1-3 Business DaysToyota 4Runner Starter

Part Number: 28100-35090-84$119.58 MSRP: $167.83You Save: $48.25 (29%)Ships in 1-3 Business DaysToyota 4Runner Starter

Part Number: 28100-35100-84$70.16 MSRP: $96.90You Save: $26.74 (28%)Ships in 1-3 Business DaysToyota 4Runner Starter

Part Number: 28100-62030-84$146.23 MSRP: $205.63You Save: $59.40 (29%)Ships in 1-2 Business DaysToyota 4Runner Starter

Part Number: 28100-65020-84$125.21 MSRP: $175.81You Save: $50.60 (29%)Ships in 1-3 Business DaysToyota 4Runner Starter

Part Number: 28100-50101-84$140.87 MSRP: $198.03You Save: $57.16 (29%)Ships in 1-3 Business DaysToyota 4Runner Starter

Part Number: 28100-31040-84$149.96 MSRP: $210.92You Save: $60.96 (29%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 21 Results

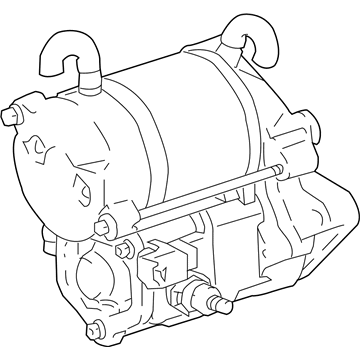

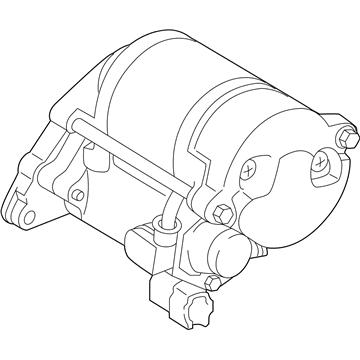

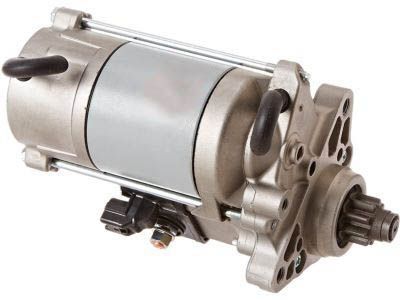

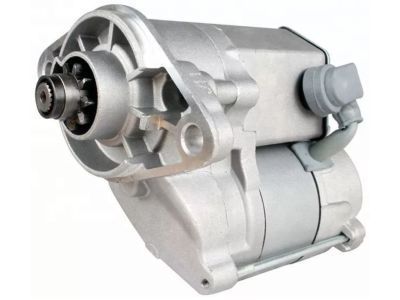

Toyota 4Runner Starter Motor

Choose genuine Starter Motor that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Starter Motor for your Toyota 4Runner? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota 4Runner parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota 4Runner Starter Motor Parts and Q&A

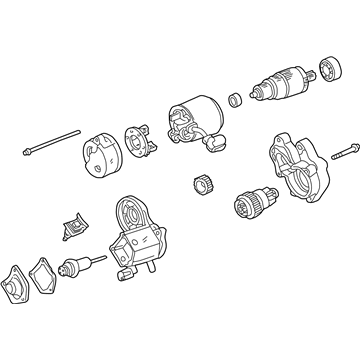

- Q: How to remove and replace the Starter Motor on Toyota 4Runner?A:Disconnection of the negative battery terminal should be the first step before taking out and installing the starter motor for both 2WD and 4WD vehicles. In order to access the engine of 2WD vehicles you must remove its rear under cover assembly by disassembling 4 bolts and detach the No. 2 manifold stay through bolt unthreading. Safely disconnect the wire harness from the cylinder block through bolt removal followed by disconnecting terminal 50 connector from the starter assembly as well as nut removal before disconnecting wire harness from terminal 30 to remove the starter assembly using its 2 bolts. The engine rear under cover assembly can be removed from the 4WD system after disconnecting the negative battery terminal. First, disconnect the heated oxygen sensor (bank 2) connector then eliminate 2 bolts, 2 nuts and separate the No. 2 front Exhaust Pipe assembly along with 2 gaskets. You can remove the front fender rear splash shield LH by dislodging its 5 clips before you loosen bolt A and detach bolt B which will separate the No. 2 steering intermediate shaft sub-assembly. After disconnecting the terminal 50 connector from the starter assembly users should remove the nut and disconnect the wire harness from terminal 30 while taking out the starter assembly with its 2 bolts.

- Q: How to install the Starter Motor and related components on Toyota 4Runner?A:The starter assembly can be installed through two bolts that need 39 Nm (400 kgf-cm, 29 ft-lbf) torque before fitting the engine wire protector to its bolted position along with attaching the starter cable with a nut torqued to 9.8 Nm (100 kgf-cm, 86 in-lbf) and adjusting the starter connector. Initiate installation of the air pump assembly followed by the rear water by-pass joint RH by mounting 2 new gaskets onto the cylinder head while torqueing the 4 nuts alternately to 18 Nm (185 kgf-cm, 13 ft-lbf). Begin by placing a new O-ring for the water by-pass pipe sub-assembly followed by soapy water application on the O-ring before inserting the pipe end into the Water Pump hole while securing it with an 18 Nm (185 kgf-cm, 13 ft-lbf) bolt torques and fixing the wire clamp on the bracket. Secure the intake manifold assembly by placing two new gaskets before installing six bolts along with two nuts which should be torqued to 18 Nm (185 kgf-cm, 13 ft-lbf). After installing the engine wire with 3 bolts torqued to 8.2 Nm (83 kgf-cm, 72 in-lbf) users should connect the water temperature sensor then the throttle position sensor before attaching all 8 fuel injector connectors. The installation of the fuel vapor feed hose assembly includes the No. 2 fuel hose and its connected fuel hose before installing the air cleaner hose assembly. Engine coolant is added while both fuel and engine coolant systems undergo leak inspections. The last step involves attaching the throttle body cover sub-assembly followed by torquing it to 7.5 Nm (80 kgf-cm, 66 in-lbf) before reconnecting the battery negative terminal.