×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Scion xB Knock Sensor

Engine Knock Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Knock Sensors found

Scion xB Knock Sensor

Part Number: 89615-06010$138.05 MSRP: $195.42You Save: $57.37 (30%)Ships in 1-3 Business Days

Scion xB Knock Sensor

Choose genuine Knock Sensor that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Knock Sensor for your Scion xB? Our website is your one-stop destination. We stock an extensive selection of genuine Scion xB parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

The Knock Sensor is truly an important part of car that boosts the dependability and efficacy of Scion xB automobiles. This is an enhanced gadget and it was used mainly to sense engine knock, it is a condition that happens when the ignition timing is off and the gadget has an important duty of enhancing proper running of the engine. Through the transmitting of real-time signals to the powertrain control module (PCM), the Knock Sensor thus makes accurate alterations to the ignition timing which minimizes detonation, thus providing a smooth running engine. Piezoelectric knock sensors installed in all Scion xB models are instrumental in monitoring engine vibrations constantly, thus the models' efficiency and safety are improved. Electronically controlled cylinder-specific ignition timing is one feature of advanced technology in Scion xB cars; another feature is the control over boost pressure. This does not only safeguard the engine in cases where it can be possibly damaged by the fuels but can also be utilized for tuning or attaining more horsepower utilizing those fuels that are of a lower octane rating. Being one of the models that embodies the box shaped of car, the Scion xB has gained reputation in terms of reliability and this has been enhanced by the efficiency of Knock Sensor. The Knock Sensor works with many xB models, and is a critical component of the vehicle, including accelerating power, fuel economy, and safety personas. Indeed due to its interesting features and good performance on the road, Knock Sensor continues to play an important role in improving the experience of driving the Scion xB.

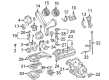

Scion xB Knock Sensor Parts and Q&A

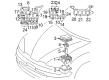

- Q: How to install the knock sensor and complete the assembly process on Scion xB?A:Installing the knock sensor begins with tightening the nut to 20 Nm (205 kgf-cm, 15 ft-lbf) while connecting the sensor connector. After inserting the No. 1 Intake Manifold insulator you must place a new gasket into the intake manifold before torquing 5 bolts and 2 nuts to 30 Nm (306 kgf-cm, 22 ft-lbf). First secure the wire harness clamp on the intake manifold before uniting the check valve hose with the union. Afterwards install the ventilation hose. The installation of fuel delivery pipe sub-assembly starts with its combination with fuel tube sub-assembly followed by fuel tube sub-assembly installation. The vehicle requires installation of its Throttle Body assembly before adding the outer cowl top panel and dual front Wiper Motor and link assemblies and right and left cowl top ventilator louvers. The installation sequence includes applying the hood to cowl top seal followed by both front wiper arm and blade assembly installation for left and right sides before adding the windshield wiper arm cover. The air cleaner cap sub-assembly needs installation with the No. 1 air cleaner hose before adding engine coolant then checking for leaks and installing the No. 1 engine cover.

- Q: How to replace the Knock Sensor on Scion xB?A:Replacing the Knock Sensor requires the engine coolant drainage followed by air cleaner assembly separation and accelerator control cable disconnection. Start by taking off the transmission oil level gauge sub-assembly and transmission oil filler tube sub-assembly that belong to the A/T transaxle but then separate the Throttle Body assembly while disconnecting the ISC valve connector along with the throttle position sensor connector (for M/T transaxle) followed by removing the wire harness clamp and the bolt and two nuts which unmount the accelerator control cable bracket and throttle body and finally remove the gasket from the Intake Manifold. After removing the four nuts from the cylinder head cover No.2 follow these steps: disconnect the radiator hose inlet, remove the oil level gauge sub-assembly, detach the ventilation hose and union to connector tube hose, and then lose three wire harness clamps before removing the three bolts and two nuts in the specified sequence and the gasket from the intake manifold. To install the new knock sensor the Special Service Tool: 09816-30010 must be used to separate the sensor from its connector but torque it to 44 N.m (450 kgf.cm, 32 ft.lbf) when replaced. Install the intake manifold with new gasket while mounting three bolts and two nuts even throughout with a torque of 30 N.m (306 kgf.cm, 22 ft.lbf), attain the three wire harness clamps before reuniting the union to connector tube hose and ventilation hose. Install the oil level gauge sub-assembly following the connection of the radiator hose inlet before proceeding with cylinder head cover No.2 installation where you must tighten nut A first then nut B to 7.0 Nm (71 kgf.cm, 62 in.lbf). The new throttle assembly gasket needs installation first before securing its bolt and two nuts to 30 N.m (306 kgf.cm, 22 ft.lbf) throughout. Keep the wire harness clamp positioned and reconnect the throttle position sensor connector for (M/T transaxle) and ISC valve connector. The last sequence includes the installation of the A/T transaxle's transmission oil filler tube sub-assembly and transmission oil level gauge sub-assembly followed by accelerator control cable assembly, air cleaner assembly, engine coolant addition with leak detection methodology.