×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Land Cruiser Speed Sensor

Speed Control Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Speed Sensors found

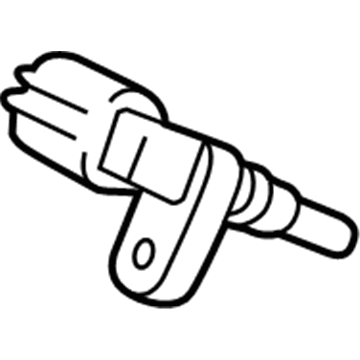

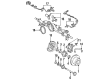

Toyota Land Cruiser Sensor, Speed, Front Driver Side

Part Number: 89543-04020$224.83 MSRP: $321.01You Save: $96.18 (30%)Ships in 1-2 Business Days

Toyota Land Cruiser ABS Sensor, Front Passenger Side

Part Number: 89542-04020$224.83 MSRP: $321.01You Save: $96.18 (30%)Ships in 1-2 Business Days

Toyota Land Cruiser Sensor, Speed, Front Driver Side

Part Number: 89543-60010$279.82 MSRP: $399.52You Save: $119.70 (30%)Ships in 1-2 Business Days

Toyota Land Cruiser Sensor, Speed, Front Passenger Side

Part Number: 89542-60040$279.82 MSRP: $399.52You Save: $119.70 (30%)Ships in 1-3 Business Days

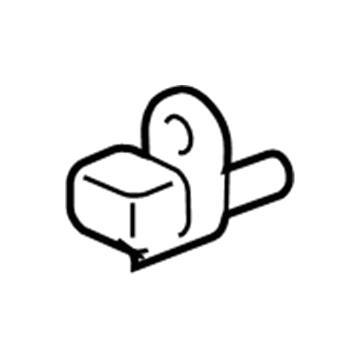

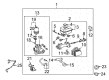

Toyota Land Cruiser Sensor, Speedometer

Part Number: 83181-12020$272.25 MSRP: $388.71You Save: $116.46 (30%)Ships in 1-2 Business DaysToyota Land Cruiser ABS Sensor, Rear Driver Side

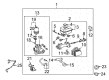

Part Number: 89546-60030$291.24 MSRP: $415.83You Save: $124.59 (30%)Ships in 1-3 Business DaysToyota Land Cruiser ABS Sensor, Rear Passenger Side

Part Number: 89545-60030$283.20 MSRP: $404.35You Save: $121.15 (30%)Ships in 1-3 Business DaysToyota Land Cruiser Rear Speed Sensor, Driver Side

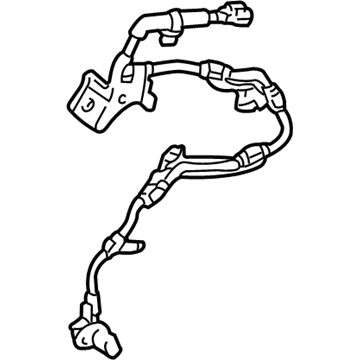

Part Number: 04895-60090$372.04 MSRP: $545.23You Save: $173.19 (32%)Ships in 1-2 Business DaysToyota Land Cruiser Rear Speed Sensor, Passenger Side

Part Number: 04895-60070$392.93 MSRP: $575.84You Save: $182.91 (32%)Ships in 1-3 Business DaysToyota Land Cruiser Front Speed Sensor

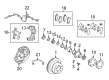

Part Number: 04895-60060$839.32 MSRP: $1230.03You Save: $390.71 (32%)Ships in 1-2 Business Days

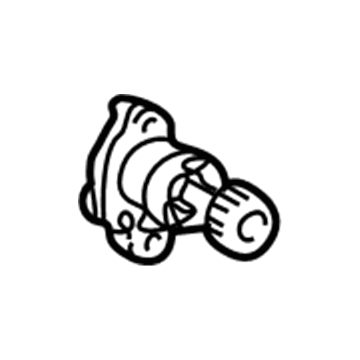

Toyota Land Cruiser Speed Sensor

Choose genuine Speed Sensor that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Speed Sensor for your Toyota Land Cruiser? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Land Cruiser parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Land Cruiser Speed Sensor Parts and Q&A

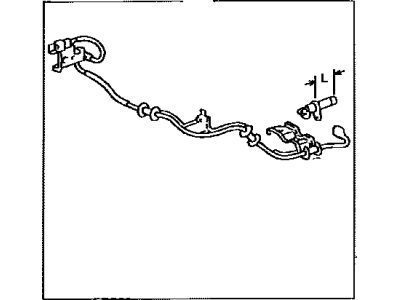

- Q: How to remove the rear speed sensors on Toyota Land Cruiser?A:Associated with removing the rear speed sensors starts with disconnecting the negative battery cable termini followed by a minimum 90-second SRS system disable period. Next, remove the rear wheel. The skid control sensor wire's removal requires users to first disconnect the speed sensor LH connector followed by unclamping 2 clamps and removing the bolt and sensor clamp while detaching 5 and 3 clamps until the speed sensor RH connector can be disconnected and the bolt and skid control sensor wire can be removed. The process to remove the rear speed sensor LH involves taking out its nut and speed sensor but you must avoid turning it during extraction. Rephrase the same procedure for the rear speed sensor RH by removing its nut and speed sensor component without rotating the parts.

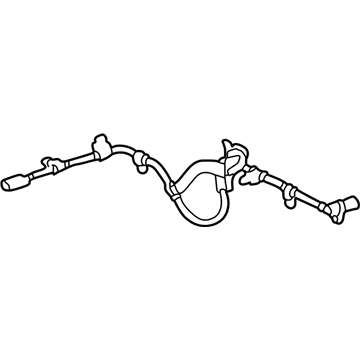

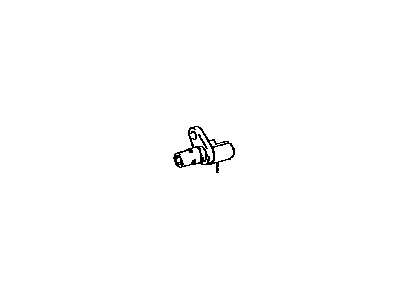

- Q: How to install the front speed sensor LH and RH on Toyota Land Cruiser?A:Utilize a 5 mm hexagon wrench to fasten the sensor using a bolt which should be tightened to 8.3 Nm (85 kgf-cm, 73 in-lbf). Inspection should reveal no iron or foreign substances on the sensor tip before inserting it into the knuckle hole while managing to avoid the tip from damage. The sensor stay part must be free of clearance and debris from the knuckle and the speed sensor rotor must be debris-free. The front skid control sensor wire LH requires attachment of the connector followed by harness clamp bolt installation with torque set at 13 Nm (127 kgf-cm, 9 ft-lbf). Alignment of wire harness and correct positioning of the clamp rotation stopper must be maintained. Fair the front skid control sensor wire LH through its connector while threading two harness clamps containing bolts with torques of 13 Nm (127 kgf-cm, 9 ft-lbf) then install a third clamp with a nut maintaining correct positioning of the clamp rotation stopper. The speed sensor connector must be securely connected as the harness clamp receives its bolt at 13 Nm (127 kgf-cm, 9 ft-lbf) torque after verifying that the bracket rotation stopper neatly touches the knuckle. The front speed sensor RH requires installation with a 5 mm hexagon wrench along with a bolt secured at 8.3 Nm (85 kgf-cm, 73 in-lbf) while following all necessary precautions regarding foreign material. You must install the front skid control sensor wire RH by placing the skid control sensor clamp on a labeled bolt at 5.0 Nm (51 kgf-cm, 44 in-lbf) and connecting the sensor while you secure two harness clamps with bolts at 13 Nm (127 kgf-cm, 9 ft-lbf). Pay attention to keeping the wire harness straight with rotation stoppers aligned. Attach a nutted harness clamp at 13 Nm (127 kgf-cm, 9 ft-lbf) while positioning the bracket rotation stopper to touch the knuckle before safely connecting the speed sensor connector. To finish installation you must install the front wheel at 131 Nm torque followed by reconnecting the negative battery terminal before testing the speed sensor signal.