×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

188 Drive Belts found

Toyota Serpentine Belt

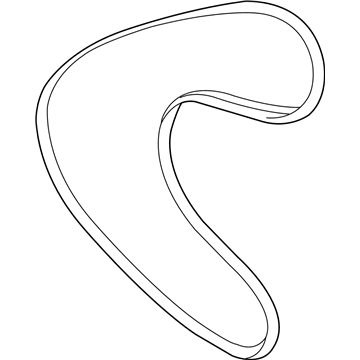

Part Number: 90916-02671$36.79 MSRP: $51.22You Save: $14.43 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, V-Ribbed; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt; Belt, V(For Fan & Alternator)

Toyota Serpentine Belt

Part Number: 90916-A2022$23.77 MSRP: $33.08You Save: $9.31 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, V-Ribbed; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; Belt, V(For Vane Pump)

- Manufacturer Note: L=1200

- Replaces: 99363-K1200

Toyota Serpentine Belt

Part Number: 90916-02664$33.21 MSRP: $46.22You Save: $13.01 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt, V-Ribbed; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt; Belt, V(For Fan & Alternator)

- Replaces: 99366-K1230

Toyota Serpentine Belt

Part Number: 90916-02679$29.50 MSRP: $41.07You Save: $11.57 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, V-Ribbed; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt; Belt, V(For Fan & Alternator)

Toyota Power Steering Belt

Part Number: 90080-91125-83$7.52 MSRP: $10.46You Save: $2.94 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, V-Ribbed; Accessory Drive Belt; Serpentine Belt Drive Kit; Serpentine Belt; Drive Belt; V-Belt

- Replaces: 90080-91125

Toyota Serpentine Belt

Part Number: 90916-02570$16.96 MSRP: $23.61You Save: $6.65 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, V-Ribbed; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt; Belt, V(For Fan & Alternator)

Toyota Power Steering Belt

Part Number: 90916-02196-83$21.62 MSRP: $30.09You Save: $8.47 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt, V, Power Steering Vane Pump; Serpentine Belt Drive Kit; Accessory Drive Belt; Serpentine Belt; Drive Belt; V-Belt; Belt

- Replaces: 99332-11205, 90916-02196-77, 90916-02196

Toyota Alternator Belt

Part Number: 90916-02378-83$11.58 MSRP: $16.12You Save: $4.54 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt, V, Fan/Alternator; Serpentine Belt Drive Kit; Serpentine Belt; Drive Belt; V-Belt

- Replaces: 90916-02302, 90916-02194, 90916-02194-83, 90916-02384, 90916-02194-77

Toyota A/C Belt

Part Number: 99332-10910-83$11.46 MSRP: $15.95You Save: $4.49 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, V; Serpentine Belt Drive Kit; Serpentine Belt; Drive Belt; V-Belt

- Replaces: 90916-02004, 99332-10910, 90916-02004-85, 99322-00910, 99332-10910-77, 99322-00910-78, 99332-60910, 99522-10911, 99332-00910, 99332-60910-78

Toyota Serpentine Belt

Part Number: 90916-A2018$31.18 MSRP: $43.39You Save: $12.21 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, V-Ribbed; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt; Belt, V(For Fan & Alternator)

- Replaces: 90916-02604

Toyota Belt

Part Number: 90916-02193-77$23.29 MSRP: $32.42You Save: $9.13 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, V, Fan/Alternator; Serpentine Belt; Drive Belt; V-Belt

- Replaces: 90916-02193, 90916-02137

Toyota Serpentine Belt

Part Number: 90916-02708$42.05 MSRP: $58.54You Save: $16.49 (29%)Ships in 1 Business DayProduct Specifications- Other Name: Belt, V-Ribbed; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt; Alternator Belt; Belt, V(For Fan & Alternator)

- Replaces: 90916-02640

Toyota Serpentine Belt

Part Number: 90916-A2034$32.13 MSRP: $44.73You Save: $12.60 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, V-Ribbed; Serpentine Belt Drive Kit; Drive Belt; V-Belt; Belt, V(For Fan & Alternator)

- Manufacturer Note: (L)

- Replaces: 90916-02754

Toyota Serpentine Belt

Part Number: 90916-02535$40.74 MSRP: $56.70You Save: $15.96 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, V-Ribbed; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt; Belt, V(For Fan & Alternator)

- Manufacturer Note: W/O(AIR CONDITIONER)

- Replaces: 90916-02468

Toyota A/C Belt

Part Number: 99364-30860-78$17.55 MSRP: $24.43You Save: $6.88 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, V-Ribbed; Accessory Drive Belt; Serpentine Belt; Drive Belt; V-Belt

- Replaces: 99364-30860

- Product Specifications

- Other Name: Belt, V; Serpentine Belt Drive Kit; Serpentine Belt; Drive Belt; V-Belt

- Product Specifications

- Other Name: Belt, V; Serpentine Belt; Drive Belt; V-Belt

- Replaces: 99332-10815-77

- Product Specifications

- Other Name: Belt, V; Accessory Drive Belt; Serpentine Belt; Drive Belt; V-Belt

- Replaces: 99364-50830, 99364-50830-78, 99364-50830-77

- Product Specifications

- Other Name: Belt, V; Serpentine Belt; Drive Belt; V-Belt

- Replaces: 99363-01050

- Product Specifications

- Other Name: Belt, V, Fan/Alternator; Serpentine Belt Drive Kit; Drive Belt; V-Belt

- Replaces: 90916-02216, 99365-01010-77, 90916-02216-77, 99365-01010

| Page 1 of 10 |Next >

1-20 of 188 Results

Toyota Drive Belt

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Drive Belt? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

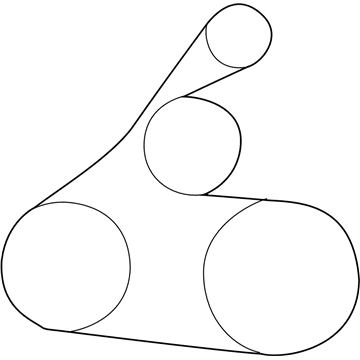

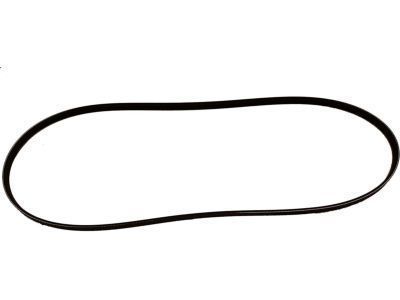

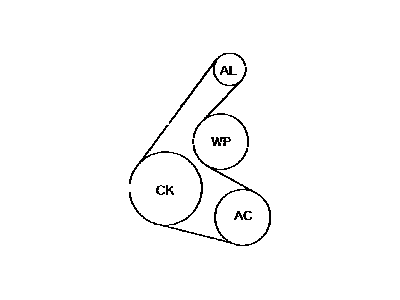

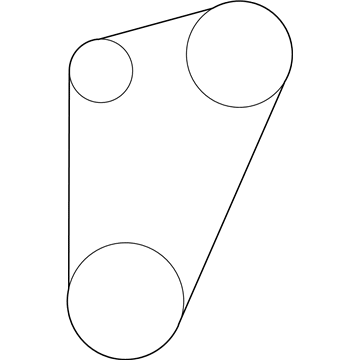

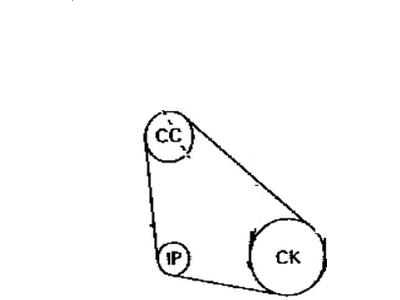

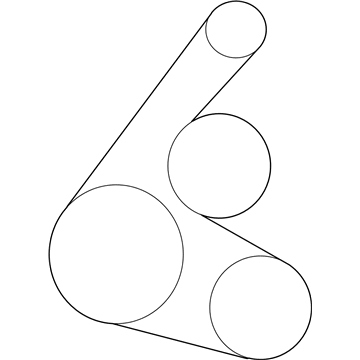

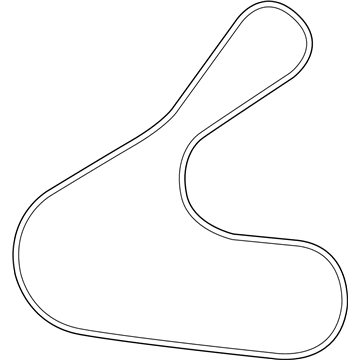

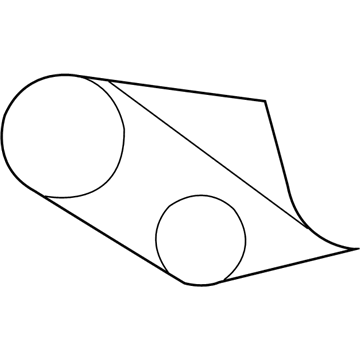

Toyota Drive Belt is applied to rotate crankshaft power to important engine components in a reliable and consistent manner. The approach that made Toyota gain worldwide loyalty was to produce cars using a lean production system that reduces waste, allows line workers to identify problems quickly, and directs the saved effort directly to improved driving experiences. In hybrids, plug-in models and traditional powered vehicles, Toyota continues improving its Hybrid Synergy Drive technology to ensure that drivers experience greater torque, reduced fuel costs, and fewer trips to the gas pump. The new TNGA platform reduces center of gravity, sharpens handling, and bakes additional crash protection, which has Toyota viewing efficiency and safety as mutually exclusive objectives. Its recent plug-in RAV4 extends the electric range to 42 miles and the gas engine just switches on when necessary, highlighting how Toyota manages to strike a balance between practicality and creativity in day-to-day commuters. Drive Belt in the engine bay, a belt that encompasses the crankshaft pulley and rotates around the engine components of the alternator, water pump, power-steering device, and A/C compressor and cuts down the frictional loss. The current serpentine Drive Belt is made of synthetic rubber and cords that run internally and do not crack or become stretchy even after over 100,000 miles of mixed idling and highway pulls. In contrast with the old V-belts which could only carry one component, one Drive Belt can hold the components and it is easy to route, minimizes the number of replacement parts, and creates more space in the engine layouts. Once wear has become evident in the form of glazing, frays or squeals, a new Drive Belt is slipped on in minutes and full component power is available again before it is too late.

Toyota Drive Belt Parts and Q&A

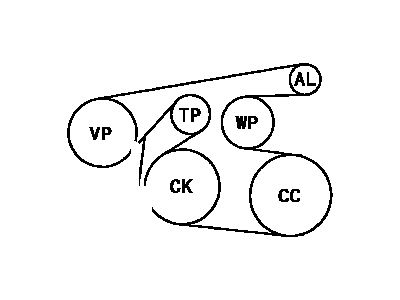

- Q: How to replace the fan and generator drive belt on Toyota 4Runner?A:For a successful fan and generator V belt replacement one must start by removing the engine under cover sub-assembly No.1 through its 4 bolt removal. The V-ribbed belt removal step begins by slowing the belt tension through counterclockwise motion on the belt tensioner. Start the V-ribbed belt tensioner assembly inspection process by rotating it clockwise followed by counter-clockwise motion to confirm no obstacles exist before performing a tensioner replacement if needed. The correct procedure for installing the new V-ribbed belt involves first turning the belt tensioner counterclockwise followed by placing it within the holes before applying a 6 mm (0.24 inch) bar to maintain tension. After installing the V-ribbed belt, users should take out the 6 mm (0.24 inch) bar as they continue to turn the belt tensioner counterclockwise. Struggling during belt installation requires position of the V-ribbed belt across all components except the P/S pump before accomplishing tension release for fitting the belt to the P/S pump. Reinstall the engine under cover sub-assembly No.1 through the 4 bolts while tightening them to 29 Nm (296 kgf-cm, 21 ft. lbs.).

- Q: How to service the drive belt on Toyota Tacoma?A:The first procedure for drive belt service involves removal of the PS pump drive belt on 2RZ-FE, 3RZ-FE, and 5VZ-FE engines followed by the engine under cover. The proper next step includes beginning by loosening the idle pulley lock nut to 39 N.m (400 kgf.cm, 29 ft.lbf) before removing the compressor drive belt through releasing the drive belt tension using the adjusting bolt. Before placing the new drive belt properly in position temporarily tighten the idle pulley lock nut to 2.5 N.m (25 kgf.cm, 22 in.lbf). You can achieve proper drive belt tension by adjusting the bolt to 160 + 25 lbf for new belts while used belts need 100 + 25 lbf. The replacement process ends by securing the idle pulley lock nut to 39 N.m (400 kgf.cm, 29 ft.lbf) and reattaching the PS pump drive belt before the engine under cover restoration.

Related Toyota Parts

Browse Toyota Drive Belt by Models

Tacoma 4Runner Camry Tundra Corolla RAV4 Highlander Prius Sienna Land Cruiser Pickup FJ Cruiser 86 Sequoia T100 Avalon Celica Supra Yaris MR2 Matrix Solara Venza GR86 Echo C-HR Cressida Grand Highlander Paseo Previa Corolla Cross Corolla iM Crown GR Corolla MR2 Spyder Starlet Tercel Van Yaris iA GR Supra