×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

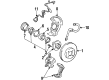

OEM Toyota Brake Proportioning Valve

Proportioning Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

62 Brake Proportioning Valves found

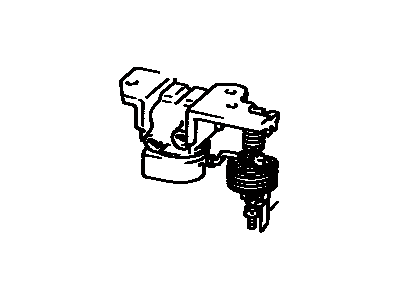

Toyota Valve Assembly

Part Number: 47150-12230$317.80 MSRP: $453.75You Save: $135.95 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Valve Assembly, Proportioning; Brake Proportioning Valve; Pressure Metering Valve

- Replaces: 47150-12050

Product Specifications

Product Specifications- Other Name: Valve Assembly, Proportioning; Brake Proportioning Valve

- Manufacturer Note: W(ABS)

Toyota Pressure Metering Valve

Part Number: 47150-20270$317.80 MSRP: $453.75You Save: $135.95 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Valve Assembly, Proportioning; Brake Proportioning Valve

Toyota Pressure Metering Valve

Part Number: 47150-12270$317.70 MSRP: $453.60You Save: $135.90 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Valve Assembly, Proportioning; Brake Proportioning Valve

- Replaces: 47150-12060

Toyota Valve Assembly

Part Number: 47150-20250$317.70 MSRP: $453.60You Save: $135.90 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Valve Assembly, Proportioning; Brake Proportioning Valve; Pressure Metering Valve

- Manufacturer Note: W(ABS)

- Replaces: 47150-42030

Toyota Pressure Metering Valve

Part Number: 47150-33070$317.80 MSRP: $453.75You Save: $135.95 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Valve Assembly, Proportioning; Brake Proportioning Valve

Toyota Pressure Metering Valve

Part Number: 47150-20370$317.70 MSRP: $453.60You Save: $135.90 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Valve Assembly, Proportioning; Brake Proportioning Valve

- Manufacturer Note: W(ABS)

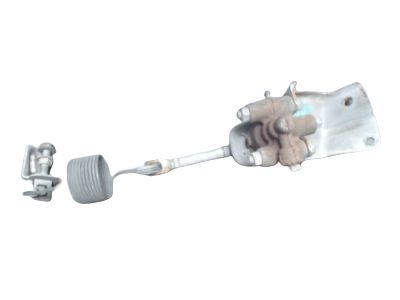

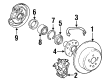

Toyota Load Proportioning Valve

Part Number: 47900-28201$320.76 MSRP: $457.96You Save: $137.20 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Valve Assembly, Load Sensing With Spring; Brake Proportioning Valve

- Replaces: 47900-28200

Product Specifications

Product Specifications- Other Name: Valve Assembly, Load Sensing With Spring; Brake Proportioning Valve

- Replaces: 47900-35490

Product Specifications

Product Specifications- Other Name: Valve Assembly, Load Sensing With Spring; Brake Proportioning Valve

- Replaces: 47910-35440, 47910-35160, 47910-35210

Product Specifications

Product Specifications- Other Name: Valve Assembly, Proportioning; Brake Proportioning Valve; Pressure Metering Valve; Valve

- Manufacturer Note: *86

Product Specifications

Product Specifications- Other Name: Valve Assembly, Proportioning; ABS Modulator Valve; Brake Proportioning Valve; Pressure Metering Valve

- Replaces: 47150-12110

Product Specifications

Product Specifications- Other Name: Valve Assembly, Proportioning; Brake Proportioning Valve

- Replaces: 47150-16040

Product Specifications

Product Specifications- Other Name: Valve Assembly, Proportioning; Brake Proportioning Valve; Pressure Metering Valve

- Product Specifications

- Other Name: Valve Assembly, Load Sensing With Spring; Valve Assembly, Load Sensing W/Spring

- Manufacturer Note: W(*66)

- Product Specifications

- Other Name: Valve Assembly, Load Sensing With Spring; Brake Proportioning Valve

- Replaces: 47900-35491

- Product Specifications

- Other Name: Valve Assembly, Proportioning; Brake Proportioning Valve

- Manufacturer Note: MEXICO SPEC

- Product Specifications

- Other Name: Valve Assembly, Proportioning; Brake Proportioning Valve; Valve Assembly, Proportioning & By-Pass

- Product Specifications

- Other Name: Valve Assembly, Proportioning; Brake Proportioning Valve

- Product Specifications

- Other Name: Valve Assembly, Proportioning; Brake Proportioning Valve

| Page 1 of 4 |Next >

1-20 of 62 Results

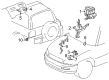

Toyota Brake Proportioning Valve

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Brake Proportioning Valve? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

Toyota Brake Proportioning Valve is applied to balance the pressure of brakes in front and rear to maintain straight and controlled stops. Toyota cuts costs in the line, allows employees to stop the manufacturing process when something is not right, and releases vehicles that are light on resources but heavy on mile after mile reliability. Due to the flexible TNGA platform, Toyota reduces the center of gravity, increases rigidity in the body, and makes handling safer with no need to swell costs or weights. On the urban boulevard or the desert by-passes, their owners rave about the lineup, which is rugged with low running costs and smart hybrids that nearly free up the fuel budget but still provide the throttle with a sharp blast when the green light flickers. The quality is consistent and the same when one gets into a small hatch or a three-row SUV. The Brake Proportioning Valve is part of the hydraulic network and detects the increasing line pressure and then cuts off fluid that is directed to the rear drums and allows Toyota to have the front discs biting first when panic halting takes place on a wet road surface. A well adjusted Brake Proportioning Valve adjusts the split point with temperature and load so that tail-heavy systems do not smash the rear wheels up on hard stomps of the brake pedal. In towing downhill, Toyota uses the Brake Proportioning Valve that maintains a constant brake balance without requiring a heavier master cylinder. Periodic inspections ensure that the Brake Proportioning Valve is free to move and maintain pedal feel stable season to season.

Toyota Brake Proportioning Valve Parts and Q&A

- Q: How to service and repair a Brake Proportioning Valve on Toyota Tacoma?A:You should start LSP & BV servicing by separating shackle No. 2 from its bracket through the removal of the nut along with cushion retainer and 2 cushions and collar. Disconnection of brake lines from the valve body requires the usage of Special Service Tool: 09023-00100 to remove the LSP & BV assembly. The LSP & BV service requires 2WD (except pre runner) operators to first remove the flexible hose bracket clip before disassembling the assembly by taking out 3 valve bracket mounting bolts and spacer. The removal of the flexible hose bracket mounting bolt is necessary for 4WD and pre runner systems alongside their counterparts. First separate the valve bracket by unfastening the nut and bolt with its two plate washers; afterwards detach the valve bracket and set plate from the valve body by removing the 2 nuts and flexible hose bracket for 2WD (except pre runner); however for 4WD and pre runner systems only unfasten the 2 nuts. Untie the spring from the valve by removing its retaining clip with spring then remove shackles No. 1 and No. 2 following the removal of the nut and bolt before loosening the 2 nuts and washer to separate shackle No. 1. Detach the load sensing spring through the removal of four bushings combined with two rubber plates, two collars alongside the load sensing valve boot and load sensing spring boot. Check the valve piston pin along with the load sensing contact surface for wear at a maximum threshold of 0.7 mm (0.028 inch). The first step for assembly includes placing the load sensing spring while mounting the load sensing valve boot and load sensing spring boot then installing 2 rubber plates followed by 2 collars and 4 bushings and applying lithium soap-base glycol grease to all contact surfaces. Follow up the mounting of shackle No. 1 and shackle No. 2 by making certain to tighten the nut to 13 Nm (130 kgf-cm, 9 ft. lbs.). Insert the load sensing spring through shackle No. 1 while placing two plate washers before securing it with a bolt and nut applied at 18 Nm (185 kgf-cm, 13 ft. lbs.) torque. Next, fix the load sensing spring to the valve body through the clip installation. The new valve bracket installation requires attachment of the set plate to the valve assembly through the bracket while temporarily fastening the 2 valve body nuts before bolt and nut tightening to reach 13 Nm torque (130 kgf-cm, 9 ft. lbs.). The installation process begins with securing three valve bracket mounting bolts along with a spacer while torquing them to 29 Nm (300 kgf-cm, 22 ft. lbs.) for vehicles based on 2WD (except pre runner) or by including the flexible hose bracket mounting bolt for both 4WD and pre runner models. Follow the installation procedure by using Special Service Tool: 09023-00100 to torque the brake line to 15 Nm (155 kgf-cm, 11 ft. lbs.). Shackle No. 2 receives attachment to the shackle bracket through two nuts while tightening the lock nut at 13 Nm (130 kgf-cm 9 ft. lbs.). Installation of shackle No. 2 with its pair of cushions and collar into the shackle bracket requires securing the cushion retainer by nut torque to 13 Nm (130 kgf-cm 9 ft. lbs.). After applying the correct rear axle load place the valve body so its piston touches the load sensing spring lightly before torquing mounting nuts to 13 Nm (130 kgf-cm, 9 ft. lbs.). The brake line needs bleeding as the final step before checking and adjusting the LSP & BV fluid pressure levels.

- Q: How to service and repair a Brake Proportioning Valve on Toyota Tundra?A:The service procedure for the Load Sensing Proportioning and By-Pass Valve (LSP & BV) starts by disconnecting shackle No.2 from its bracket through bushing removal until shackle No.2 comes off along with taking out the 2 bushings and collar and finally the 2 bolts and shackle bracket. Use Special Service Tool: 09751-36011 to disconnect the 3 brake lines from the valve body. Then, remove the LSP & BV assembly after disconnecting its 2 valve bracket mounting bolts. The Blend Proportioning Valve requires three securing bolts to be removed after disconnecting the four brake lines when a torque of 29 Nm (296 kgf-cm, 21 ft. lbs.) has been achieved. Install the LSP & BV assembly by first placing its position and then securing it using the 2 valve bracket mounting bolts while torquing to 29 Nm (300 kgf-cm, 22 ft. lbs.). Specially designed tool 09751-36011 is used to connect the three brake lines where torque must be set to 15 Nm (155 kgf-cm, 11 ft. lbs.). Secure dimension A to 120 mm (4.72 inch) then fasten the lock nut to 13 Nm (130 kgf-cm, 9 ft. lbs.) afterward add the shackle bracket followed by 2 bolts secured at 29 Nm (300 kgf-cm, 22 ft. lbs.). Insert the shackle bracket by connecting its bushings with collar and shackle No.2 while tightening it to 13 Nm (130 kgf-cm, 9 ft. lbs.). Install the cushion retainer and its matching nut. Position the valve body by manually pulling down the load sensing spring which should move valve piston down smoothly until the piston lightly touches the spring. Tighten its mounting nuts to 13 Nm (130 kgf-cm, 9 ft. lbs.). Brake line bleeding must occur before checking and adjusting fluid pressure levels of both the LSP and BV.