×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Scion xB Cylinder Head Gasket

Engine Cylinder Head Gasket- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Cylinder Head Gaskets found

Scion xB Head Gasket

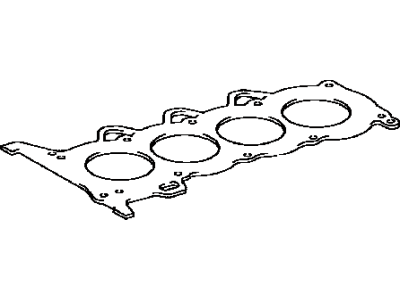

Part Number: 11115-21091$42.05 MSRP: $58.54You Save: $16.49 (29%)Ships in 1-3 Business Days

Scion xB Head Gasket

Part Number: 11115-28040$74.52 MSRP: $104.61You Save: $30.09 (29%)Ships in 1-3 Business Days

Scion xB Cylinder Head Gasket

Choose genuine Cylinder Head Gasket that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Cylinder Head Gasket for your Scion xB? Our website is your one-stop destination. We stock an extensive selection of genuine Scion xB parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

The Cylinder Head Gasket is a crucial part well recognized for durability and efficiency, and has a critical responsibility of ensuring the general performance of the vehicle's engine and its safety. Working to fit the engine block and cylinder head shut, the Cylinder Head Gasket ensures that combustion gases do not spill out while at the same time ensuring that coolant and oil are contained to avoid cases of overheating of the engine and consequent damage of the same. Contemporary models of Scion xB have a more developed design of Multi-Layer Steel (MLS), that increases the strent ghness and efficiency of the car, so Scion xB keeps its high performance at any period of time. It fits different xB models that have 1.5L 1NZ-FE and 2.4L 2AZ-FE engine, and this proves that Cylinder Head Gasket is very versatile. This component is important in avoiding such problems like leakage of coolant, power drainage that may be caused by a faulty head gasket where signs like white smoke from the exhaust may be evident. Service of the Cylinder Head Gasket ought to be done frequently to ensure that the engine is not compromised and has a longer life span. Furthermore, in the field of automobile industries and markets, the Cylinder Head Gasket can also be remarked as exceptional and indispensable part as it indeed appears to be constructed of tough materials and mandated for improving the safety and economy of the car while undoubtedly, the Cylinder Head Gasket is highly recommended for the car owners of Scion xB as it is quite reliable and performs very effectively in the world of automobiles.

Scion xB Cylinder Head Gasket Parts and Q&A

- Q: How to replace the cylinder head gasket on Scion xB?A:The replacement procedure for cylinder head gasket begins with fuel pressure discharge followed by chain sub-assembly removal and front Exhaust Pipe separation through the removal of two bolts and two compression springs. The replacement process starts with removing No.1 exhaust manifold heat insulator through 4 bolts before moving onto the manifold support bracket by detaching its 3 bolts. Start by removing the air cleaner assembly followed by accelerator control cable assembly separation and finally remove the Throttle Body assembly. Beginning with engine wire disconnection the technician follows by removing the water filler sub-assembly after detaching the radiator inlet hose as well as radiator hose No.3 and radiator reservoir tank hose together with the removal of 2 bolts. To remove the Intake Manifold maintain the recommended sequence for unbolting 3 bolts and 2 nuts while simultaneously removing the gasket substance. Pull out the oil level gauge guide after removing both the gauge along with its bolt. The first task removes the union to check valve hose between the brake booster and the radiator hose inlet from the union connection. The fuel tube sub-assembly needs Special Service Tool: 09268-21010 to disconnect it while letting go of the heater water inlet hose A that is attached to water bypass pipe No. 2. The open-ended bolt on water by-pass pipe No.1 needs to be unscrewed to separate the pipe. Users must rotate the crankshaft 40 degrees counterclockwise from TDC and align the oil jet hole with the timing mark to protect piston valves before the process of loosening and removing 19 bearing cap bolts and 9 bearing caps and the No. 1 and No. 2 Camshafts when keeping the camshaft at a level position. The cylinder head sub-assembly requires uniform loosening of 10 bolts using an 8 mm bi-hexagon wrench in specified sequence before the removal of the cylinder head gasket avoiding washer separation into the cylinder head. Measure the set bolt length on the cylinder head with vernier calipers to check standard limits of 142.8 to 144.2 mm and maximum limit of 147.1 mm. Replace any set bolts that exceed the maximum limit. Position a new cylinder block gasket with the Lot No. stamp oriented upwards and oil-free surface on the cylinder block before carefully placing the cylinder head on the gasket. To install the cylinder head sub-assembly use a continuous bead of seal packing with 3.5 to 4.5 mm diameter while cleaning the contact surface from oil before oil pan installation within 3 minutes. Use a light coating of engine oil on the cylinder head bolt threads before installing the 10 bolts with plate washers along with a uniform 8 mm bi-hexagon wrench application up to 29 Nm torque, then apply paint marks on bolt fronts with subsequent bolt tightening by another 90 degrees to achieve 180-degree opposite front bolt positions. The camshaft needs engine oil applied to its journals before positioning it on the cylinder head with the timing mark above while tightening the bolts initially to 13 Nm followed by bearing cap No. 1 installation with a torque of 23 Nm. Water by-pass pipe No.1 receives a bolt torqued to 9.0 Nm and the installation includes connecting the fuel tube sub-assembly and adding the oil level gauge guide with new O-ring and bolt torqued to 9.0 Nm. Place a new gasket on the intake manifold then secure and tighten the manifold joints between the 3 bolts and 2 nuts with force of 30 Nm. The procedure involves installing both water filler sub-assembly bolts to 7.5 Nm torque specifications alongside reattaching radiator hoses and mounting throttle body assembly framework and air cleaner assembly with manifold support bracket using 3 bolts torquing at 37 Nm. Use 4 bolts with 8.0 Nm torque to mount the heat insulator on the exhaust manifold No.1 before installing the exhaust pipe front assembly with new gasket material. The two compression springs should be added alongside two bolts which must be torqued to 43 Nm. The last step includes the installation of the chain sub-assembly followed by engine oil addition and leak inspections for both oil and coolant systems and fuel.

- Q: How to install the cylinder head gasket on Scion xB?A:You should begin with the 2AZ-FE engine cylinders by placing a new gasket on the block surface that has the Lot No. stamp facing up toward you. For this step follow a proper installation direction while also removing all oil residue from contact areas. The installation process requires carefully setting the cylinder head onto the gasket followed by cylinder bolt installation with engine oil on the bolt threads and under their heads. Use a 10 mm bi-hexagon wrench to achieve 70 Nm (714 kgf-cm, 52 ft-lbf) torque when tightening the 10 cylinder head set bolts and plate washers according to specified installation order. Mark the bolts' front faces with paint while torquing them an additional 90 degrees to produce a 90 degrees angle to the front direction. After the No. 1 and No. 2 Camshaft bearings are installed, position the camshafts and join the inlet and outlet heater water hoses. Connect the inlet radiator hose then secure the engine wire together with various connectors while installing the ground cable with 8.4 Nm (86 kgf-cm, 74 in-lbf) torque. Set the crankshaft key to its left horizontal position to properly position the yellow mark links on timing marks before secure temporary fastening of the oil pump drive shaft sprocket. Put the damper spring into the adjustment hole before installing the chain tensioner plate with 12 Nm of torque (122 kgf-cm, 9 ft-lbf) and lock the oil pump drive shaft using 30 Nm of torque (301 kgf-cm, 22 ft-lbf). Install the crankshaft timing gear or sprocket followed by the No. 1 chain vibration damper (torque: 9.0 Nm (92 kgf-cm, 80 in-lbf)) for the chain sub-assembly while keeping the No. 1 cylinder at TDC/compression and setting the timing marks correctly. Position and secure the chain tensioner slipper with torque to 19 Nm (194 kgf-cm, 14 ft-lbf) then add the timing chain guide with a torque setting of 9.0 Nm (92 kgf-cm, 80 in-lbf) and the No. 1 Crankshaft Position Sensor plate. The timing chain cover requires Toyota Genuine Seal Packing Black or equivalent alongside Three Bond 1207B or equivalent which must be applied to its surface before installing the cover along with 12 bolts and 2 nuts according to marked torque specifications. The mechanic should install the No. 1 chain tensioner assembly which requires a torque setting of 9.0 Nm (92 kgf-cm, 80 in-lbf) along with V-ribbed belt tensioner assembly (torque: 60 Nm (607 kgf-cm, 44 ft-lbf)) and transverse engine mounting bracket (torque: 55 Nm (561 kgf-cm, 41 ft-lbf)). Secure the crankshaft pulley by using Service Tool: 09213-54015 91651-60855 to install and torque its bolt to 180 Nm (1835 kgf-cm, 133 ft-lbf). The installation requires the oil pan sub-assembly including its seal packing to achieve 9.0 Nm (92 kgf-cm, 80 in-lbf) torque while also enabling crankshaft position sensor, idler pulley (torque: 50 Nm (510 kgf-cm, 37 ft-lbf)) and engine mounting insulator RH (torque: 95 Nm (969 kgf-cm, 70 ft-lbf)) installation. The front engine mounting insulator should be torqued at 95 Nm (969 kgf-cm, 70 ft-lbf) for bolts but through bolt and nut require 145 Nm (1479 kgf-cm, 107 ft-lbf). An exhaust manifold converter with new gasket should also be tighted at 37 Nm (377 kgf-cm, 27 ft-lbf) and heat insulator at 12 Nm (122 kgf-cm, 9 ft-lbf). Install the Intake Manifold insulator before placing the intake manifold followed by the camshaft timing oil control valve assembly and the fuel delivery pipe and the fuel main tube. Then proceed to install the oil dipstick guide fastened with 9.0 Nm (92 kgf-cm, 80 in-lbf) torque while also installing the oil dipstick followed by the cylinder head cover and Spark Plug and Ignition Coil assembly next to the Throttle Body assembly and radiator reserve tank which requires 5.0 Nm (51 kgf-cm, 44 in-lbf) torque. Position the generator assembly followed by the fan combined with generator V belt before adding the front and center Exhaust Pipe assemblies and placing the outer cowl top panel followed by the front Wiper Motor and link, cowl top ventilator louvers before setting the hood to cowl top seal and finally adding the front wiper arm and blade assemblies. To complete the procedure connect the cable to the negative battery terminal while torquing it to 5.4 Nm (55 kgf-cm, 48 in-lbf) then add oil and coolant before leak inspection followed by engine cover and under cover installation and final front wheel (torque: 103 Nm (1050 kgf-cm, 76 ft-lbf)) installation and proper hood adjustment.