×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Scion xB Control Arm

Suspension Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Control Arms found

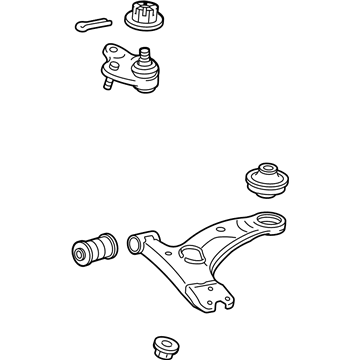

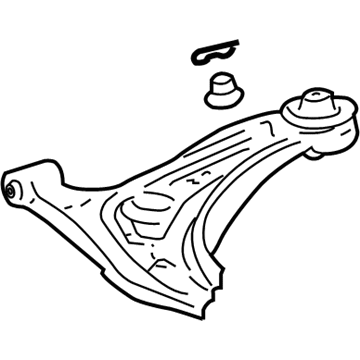

Scion xB Arm Sub-Assembly, Front Suspension, Lower Driver Side

Part Number: 48069-12300$168.48 MSRP: $238.50You Save: $70.02 (30%)Ships in 1-3 Business Days

Scion xB Lower Control Arm, Passenger Side

Part Number: 48068-12300$159.08 MSRP: $225.20You Save: $66.12 (30%)Ships in 1-3 Business Days

Scion xB Lower Control Arm, Driver Side

Part Number: 48069-19156$257.08 MSRP: $367.06You Save: $109.98 (30%)Ships in 1-3 Business Days

Scion xB Lower Control Arm, Passenger Side

Part Number: 48068-59065$253.84 MSRP: $362.42You Save: $108.58 (30%)Ships in 1-3 Business Days

Scion xB Lower Control Arm, Passenger Side

Part Number: 48068-19176$257.08 MSRP: $367.06You Save: $109.98 (30%)Ships in 1-3 Business DaysScion xB Lower Control Arm, Driver Side

Part Number: 48069-59065$253.84 MSRP: $362.42You Save: $108.58 (30%)Ships in 1-3 Business Days

Scion xB Control Arm

Choose genuine Control Arm that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Control Arm for your Scion xB? Our website is your one-stop destination. We stock an extensive selection of genuine Scion xB parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

The Scion xB Control Arm can be considered as one of the most important parts that has a major impact on the durability and productivity of the Scion xB vehicles. Being one of the main parts of the car suspension system the Control Arm connects the car's frame and wheels allowing for the up-and-down movement of the wheels to be precise given the terrain that the car is on. The Control Arm designs vary from stamped steel commonly used in earlier models to stronger cast iron and lightweight aluminum in Scion xB both the first and second generation models. An aspect that can be attributed to this is flexibility in design and this has a role to play in the general reliability of the Scion xB. Control arm has bushing and ball joints for the good contact and smooth movements albeit, the wear and tear would require replacement from time to time especially for powerful driving. Of course, available performance-oriented Control Arms have been developed to tolerant higher stress loads and additional modifications to support Scion xB's stable and remarkable handling abilities. As a vehicle that has a unique and almost cube-like shape and powerful engine options, Scion xB quickly became known as rather reliable car, and the Control Arm is one of the factors for that. These features remain relevant and essential for the improvement of the overall performance of the car's suspension system as well as safety specifically for those focusing on purchasing the Scion xB models, which are part of the extended xB series.

Scion xB Control Arm Parts and Q&A

- Q: How to remove the front lower Control Arm on Scion xB?A:Start the front lower suspension arm removal process by taking off both front wheels and then removing the No. 1 engine under cover and No. 2 engine under cover and finalizing with both rear engine under covers (LH and RH). The front lower No. 1 suspension arm sub-assembly bolts (LH and RH) should only be loosened while maintaining the nuts in their original position since each nut possesses its own stopper. The process of removing the front lower No. 1 suspension arm sub-assembly LH for manual transaxle requires disconnection of the 2 bolts and nut for completion. Front wheels should be aligned in a straight direction before you lock down the steering wheel. Processing requires removal of the column hole cover silencer sheet then separation of both the No. 2 steering intermediate shaft assembly and the No. 1 steering column hole cover sub-assembly. The first step consists of using hexagon wrenches (size 6mm if required) to remove front stabilizer link assembly nuts for both left (LH) and right (RH) sides. The next step consists of unfastening tie rod end sub-assemblies (LH and RH) before removing front suspension member reinforcements (LH and RH) through their four bolts. Separate the front suspension member brace rear with 3 bolts on the LH side while applying the same approach to the RH side. The front suspension crossmember requires a transmission jack for support before you disconnect the 4 bolts and 2 nuts on all manual and automatic transaxle systems. For automatic transaxles separate the front lower No. 1 suspension arm sub-assemblies (LH and RH) by unfastening their 2 bolts and single nut yet avoid rotating the nuts.

- Q: How to install the front lower Control Arms on Scion xB?A:First install 2 bolts and a nut for each side onto the front lower No. 1 suspension arm sub-assembly RH and LH. Keep the nut from turning because it features a built-in stopper. The operation takes place on a level front suspension crossmember. The transmission jack maintains the front suspension crossmember as you insert Special Service Tool: : 09670-00020 into its reference holes on both front suspension crossmember sides. Tighten all six components (2 bolts A, 2 bolts B, 2 nuts) on each side according to the specified torque values: Bolt A - 145 Nm (1479 kgf-cm, 107 ft-lbf), Bolt B - 95 Nm (969 kgf-cm, 70 ft-lbf), Nut - 95 Nm (969 kgf-cm, 70 ft-lbf). First tighten the 3 bolts on the front suspension member brace rear LH to specifications of A - 145 Nm (1479 kgf-cm, 107 ft-lbf) and B - 93 Nm (948 kgf-cm, 69 ft-lbf) before completing the same operation with the front suspension member brace rear RH. Insert the front suspension member reinforcement LH and RH with 4 bolts each at 96 Nm (979 kgf-cm, 71 ft-lbf) torque but first tighten bolts A and B temporarily before securing them in sequence with C, B, D, and A. The front lower No. 1 suspension arm sub-assembly LH for manual transaxle needs 2 bolts and a nut where the nut must stay untightened. Install the sub-assemblies of front lower No. 1 suspension arm in both LH and RH positions before connecting the sub-assemblies of tie rod ends and front stabilizer link assemblies LH and RH using a torque of 74 Nm (755 kgf-cm, 55 ft-lbf). If needed, use a hexagon wrench (6mm) to complete the installation. Install the front wheels while tightening the engine under covers, column hole cover silencer sheet and No.1 steering column hole cover sub-assembly along with the No.2 steering intermediate shaft assembly at 103 Nm (1050 kgf-cm, 76 ft-lbf) torque. The front lower No. 1 suspension arm sub-assembly needs full tightening using Special Service Tool: : 09961-01270 on bolt A to 172 Nm (1755 kgf-cm, 127 ft-lbf) torque or reach 233 Nm (2376 kgf-cm, 172 ft-lbf) torque without the tool while avoiding bolt rotation. Complete the bolt B torquing sequence to 233 Nm (2376 kgf-cm, 172 ft-lbf). Afterward, perform an inspection of both front wheel alignment and if necessary, make adjustments.