×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota RAV4 Timing Chain

Engine Timing Chain- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Timing Chains found

Toyota RAV4 Timing Chain

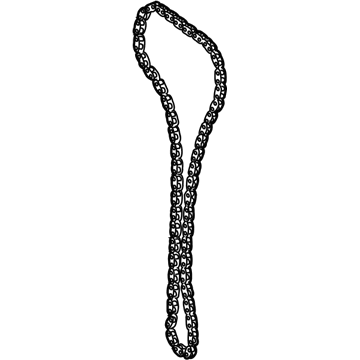

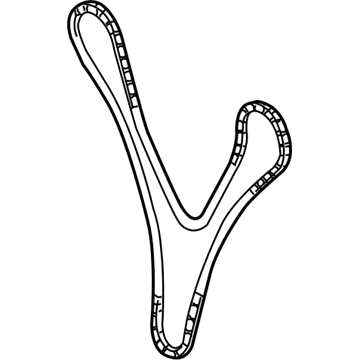

Part Number: 13506-0H011$268.87 MSRP: $383.89You Save: $115.02 (30%)Ships in 1-2 Business Days

Toyota RAV4 Timing Chain

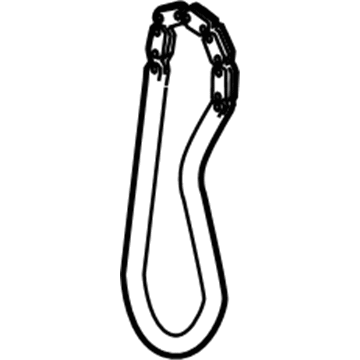

Part Number: 13507-28010$89.46 MSRP: $125.57You Save: $36.11 (29%)Ships in 1-2 Business Days

Toyota RAV4 Timing Chain

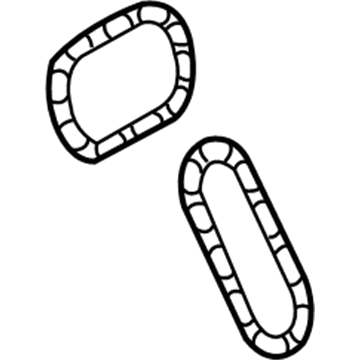

Part Number: 13507-0P010$73.58 MSRP: $103.28You Save: $29.70 (29%)Ships in 1-2 Business Days

Toyota RAV4 Timing Chain

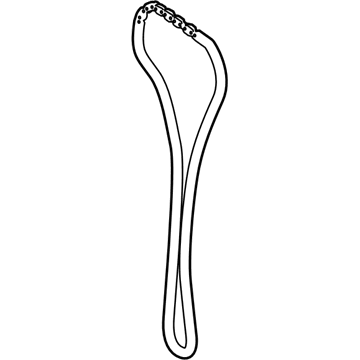

Part Number: 13506-0V010$210.74 MSRP: $300.88You Save: $90.14 (30%)Ships in 1-2 Business Days

Toyota RAV4 Timing Chain

Part Number: 13506-0P011$240.91 MSRP: $343.96You Save: $103.05 (30%)Ships in 1-2 Business DaysToyota RAV4 Timing Chain

Part Number: 13506-F0010$217.38 MSRP: $310.37You Save: $92.99 (30%)Ships in 1-3 Business Days

Toyota RAV4 Timing Chain

Choose genuine Timing Chain that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Timing Chain for your Toyota RAV4? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota RAV4 parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota RAV4 Timing Chain Parts and Q&A

- Q: How to remove and replace the timing chain on Toyota RAV4?A:A technician must start by draining engine oil before proceeding to eliminate the RH engine under cover and PS vane pump and ABS actuator along with the RH engine mounting insulator and Drive Belt and generator and air cleaner assembly followed by Ignition Coils removal. The first step involves removing the cylinder head cover through a process of disconnecting 2 PCV hoses followed by 8 bolt removal along with 2 nut removal. At TDC/compression of No. 1 cylinder enable pulley groove timing mark 0 alignment with the camshaft timing sprocket and VVT timing sprocket while bearing caps align with the numbers 1 and 2; if required, turn crankshaft one turn until proper alignment. Use tools Special Service Tool: 09213-54015 and 09330-00021 to remove the crankshaft pulley before uninstalling its bolt and pulley. The necessary tool in this step is Special Service Tool: 09950-50013 (09951-05010, 09952-05010, 09953-05020, 09954-05021) and 09950-40011 (09957-04010). Use wrenches to remove the 2 nuts from the chain tensioner followed by separating the drive belt tensioner then the Crankshaft Position Sensor and oil pan and timing chain cover requires removing the stud bolt from the drive belt tensioner while taking off 14 bolts and 2 nuts and prying the cover off very carefully. Remove the crank angle sensor plate, chain tensioner slipper, chain vibration damper, timing chain guide and timing chain then crankshaft timing sprocket and camshaft timing sprocket and VVT timing sprocket while taking care to avoid damaging the cylinder head and valve lifter. Measure the timing chain and sprocket elongation by determining the length of 16 links with a maximum permitted stretch to 122.6 mm (4.827 inch) and inspect sprocket diameter. Check the maximum wear on the chain tensioner slipper and vibration damper should be 1.0 mm (0.039 inch) while ensuring that the chain tensioner plunger moves without resistance and holds its position. The replacement process begins with removing the timing chain cover before tapping out the oil seal (Special Service Tool: 09309-37010 enables proper installation of a new component with MP grease applied to its lip. Special Service Tool: 09308-10010, 09950-60010 (09951-00200) needs to be used to take out the oil seal before installing a new one when the cover remains in place. Start your installation by setting the camshaft timing sprocket followed by the VVT timing sprocket while maintaining correct alignment and torquing them to 54 Nm (551 kgf-cm, 40 ft. lbs.). After relocating No. 1 cylinder to TDC/compression, install the two chain vibration damper bolts to 9.0 Nm (92 kgf-cm, 80 inch lbs.). Then install the crankshaft timing sprocket and timing chain with their respective mark positioning. Follow recommended torque values when installing the timing chain guide and chain tensioner slipper into their places. Attach the crank angle sensor plate followed by the timing chain cover containing seal packing (Part Number 08826-00080) while torquing the bolts according to specified values. Accomplish the installation process using specified torque values by adding the drive belt tensioner followed by the crankshaft position sensor then oil pan then crankshaft pulley with 180 Nm (1,836 kgf-cm, 132 ft. lbs.) torque followed by chain tension adjustment. To check valve timing properly set the timing marks before you install the cylinder head cover along with ignition coils, vane pump, generator, RH engine mounting insulator, drive belt, ABS actuator, air cleaner assembly, and the engine under cover. The procedure ends with engine start-up followed by leak inspection and a fresh check of engine oil level.

- Q: How to install the No. 2 Timing Chain sub-assembly on Toyota RAV4?A:After positioning the crankshaft key in the left horizontal position face the Drive Shaft cutout upward until the yellow mark links match the timing markers on each gear. The sprockets receive installation on both crankshaft and Oil Pump shaft components while the chain properly engages the gears. A temporary fastening with a nut must occur on the oil pump drive shaft sprocket. The damper spring into the adjusting hole must be inserted before installing the chain tensioner plate using a bolt tightened to 12Nm (122 kgf-cm, 9ft-lbf). Secure the oil pump drive shaft sprocket into its adjusting hole while matching the groove of the pump. Then use a 4 mm diameter bar to set the gear in position before torquing the nut to 29.5 Nm (301 kgf-cm, 22 ft-lbf). The assembly process includes installing the crankshaft timing sprocket using two bolts that should be tightened to 9.0 Nm (92 kgf-cm, 80 in-lbf) and adding the No. 1 chain vibration damper before securing it with these bolts. First set the No. 1 cylinder to TDC/compression position while turning the Camshafts until the timing marks align correctly. Then position the chain to install it on the crankshaft timing sprocket with the gold or orange mark link facing the timing mark. To install the crankshaft timing sprocket use Special Service Tool: 09309-37010 with a hammer to tap it in until reaching final positioning. Then line up each timing mark with a gold or yellow link before placing the chain. Secure the chain tensioner slipper with a bolt that requires 19 Nm (194 kgf-cm, 14 ft-lbf) torque before installing the timing chain guide with its bolt tightened to 9.0 Nm (92 kgf-cm, 80 in-lbf). The installation of the No. 1 Crankshaft Position Sensor plate must be done with the "F" mark oriented towards the front while also replacing the timing chain cover sub-assembly through this process after removing discarded packing material and using seal packing (Diameter 4.0 to 4.5 mm (0.157 to 0.177 in.)) yet maintaining the installation period within three minutes and abstaining from adding engine oil during the first two hours. The timing chain cover installation requires tightening of 12 bolts and 2 nuts according to different torque settings including 9.0 Nm (92 kgf-cm, 80 in-lbf), 25 Nm (255 kgf-cm, 18 ft-lbf), 55 Nm (561 kgf-cm, 41 ft-lbf), and 11 Nm (112 kgf-cm, 8 ft-lbf). Install the V-ribbed belt tensioner stud bolt while using "TORX" socket E10 technology and torque the bolt to 21.5 Nm (219 kgf-cm, 16 ft-lbf). To install the No. 1 chain tensioner assembly begin by releasing the ratchet pawl after you push in the plunger and hook it to the pin while using two nuts torqued to 9.0 Nm (92 kgf-cm, 80 in-lbf). After installing the bolt and nut for the V-ribbed belt tensioner to 59.5 Nm (607 kgf-cm, 44 ft-lbf) torque value, place the engine mounting bracket RH with 3 bolts torqued to 55 Nm (561 kgf-cm, 41 ft-lbf). Utilize Special Service Tool: 09213-54015 91651-60855 to fix the crankshaft pulley in position before tightening the bolt to 180 Nm (1,835 kgf-cm, 133 ft-lbf) to achieve correct plunger extension when rotating the crankshaft. Application of seal packing (Diameter 3.0 to 4.0 mm (0.118 to 0.157 in.)) should be performed prior to installing the oil pan sub-assembly within 3 minutes because adding engine oil is prohibited for at least 2 hours. Install the subassembly while tightening the 12 bolts and 2 nuts in sequence to 9.0 Nm (92 kgf-cm, 80 in-lbf). Set the transmission jack below the engine gap before unthreading the chain block together with its hangers. The cray position sensor installation must occur before setting the cylinder head cover sub-assembly after removing old packing material and applying seal packing. Then secure the 8 bolts and 2 nuts with the specified torque values starting at 11 Nm (112 kgf-cm, 8 ft-lbf), followed by 14 Nm (143 kgf-cm, 10 ft-lbf) and finishing at 11 Nm (112 kgf-cm, 8 ft-lbf). Guide the 2 engine wires into place using 2 bolts before torquing them to 8.4 Nm (86 kgf-cm, 74 in-lbf). Place the ventilation hoses immediately after. The idler pulley should be installed with two bolts reaching 60 Nm of torque before you move to the engine mounting insulator RH which requires 4 bolts and 2 nuts at 95 Nm (969 kgf-cm, 70 ft-lbf) and 52 Nm (530 kgf-cm, 38 ft-lbf). Connect the 2 clamps of the engine wire then install the wire harness protector using a bolt. Apply torque of 95 Nm (969 kgf-cm, 70 ft-lbf) on the 2 mounting insulator FR bolts before tightening the through bolt along with its nut to 145 Nm (1,479 kgf-cm, 107 ft-lbf). The installation process ends with adding engine oil after the radiator reservoir (5.0 Nm / 51 kgf-cm / 44 in-lbf), generator assembly and fan and generator V belt, front suspension member reinforcement RH, front Exhaust Pipe and seating the radiator reservoir with two bolts (5.0 Nm / 51 kgf-cm / 44 in-lbf). First connect the cable to the negative battery terminal and then inspect for both engine oil and exhaust gas leaks before installing two nuts on the No. 1 engine cover with a torque of 7.0 Nm (71 kgf-cm, 62 in-lbf). Next install the front fender apron RH followed by the No. 1 engine under cover and front wheel RH and radiator support opening cover.