×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Corolla Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

96 Axle Shafts found

Toyota Corolla Axle Assembly, Driver Side

Part Number: 43420-01031-84$335.33 MSRP: $505.31You Save: $169.98 (34%)Ships in 1-3 Business DaysToyota Corolla Axle Assembly, Driver Side

Part Number: 43420-02031-84$346.72 MSRP: $521.57You Save: $174.85 (34%)Ships in 1-3 Business DaysToyota Corolla Axle Assembly, Passenger Side

Part Number: 43410-02091$468.34 MSRP: $686.36You Save: $218.02 (32%)Ships in 1-3 Business DaysToyota Corolla Axle Assembly, Driver Side

Part Number: 43420-02320$404.05 MSRP: $592.14You Save: $188.09 (32%)Ships in 1-3 Business DaysToyota Corolla Axle Assembly, Driver Side

Part Number: 43420-02360$387.70 MSRP: $568.18You Save: $180.48 (32%)Ships in 1-3 Business DaysToyota Corolla Axle Assembly, Front Passenger Side

Part Number: 43410-20463$466.97 MSRP: $684.35You Save: $217.38 (32%)Ships in 1-3 Business DaysToyota Corolla Axle Assembly, Front

Part Number: 43410-20442$469.19 MSRP: $687.59You Save: $218.40 (32%)Ships in 1-3 Business DaysToyota Corolla Axle Assembly, Passenger Side

Part Number: 43410-12C10$393.15 MSRP: $576.17You Save: $183.02 (32%)Ships in 1-3 Business DaysToyota Corolla Axle Assembly, Passenger Side

Part Number: 43410-01140$446.95 MSRP: $655.02You Save: $208.07 (32%)Ships in 1-3 Business DaysToyota Corolla Axle Assembly, Front

Part Number: 43420-12313$399.51 MSRP: $585.48You Save: $185.97 (32%)Ships in 1-3 Business DaysToyota Corolla Axle Assembly, Passenger Side

Part Number: 43410-02C12$439.35 MSRP: $643.87You Save: $204.52 (32%)Ships in 1-3 Business DaysToyota Corolla Axle Shafts

Part Number: 42340-32090$417.93 MSRP: $612.49You Save: $194.56 (32%)Ships in 1-3 Business DaysToyota Corolla Axle Assembly, Passenger Side

Part Number: 43410-12B50$439.35 MSRP: $643.87You Save: $204.52 (32%)Ships in 1-3 Business DaysToyota Corolla Axle Assembly, Passenger Side

Part Number: 43410-02C10$439.35 MSRP: $643.87You Save: $204.52 (32%)Ships in 1-3 Business DaysToyota Corolla Axle Assembly, Front Passenger Side

Part Number: 43410-12081$442.24 MSRP: $648.11You Save: $205.87 (32%)Ships in 1-3 Business Days

Toyota Corolla Axle Assembly, Driver Side

Part Number: 43420-01120$400.76 MSRP: $587.32You Save: $186.56 (32%)

| Page 1 of 5 |Next >

1-20 of 96 Results

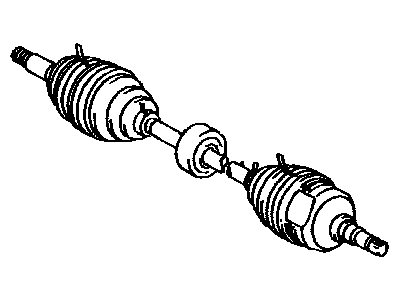

Toyota Corolla Axle Shaft

Choose genuine Axle Shaft that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Axle Shaft for your Toyota Corolla? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Corolla parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Corolla Axle Shaft Parts and Q&A

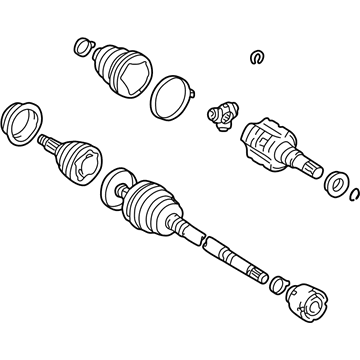

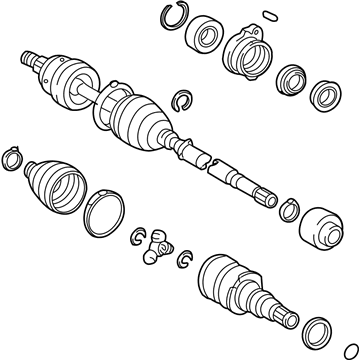

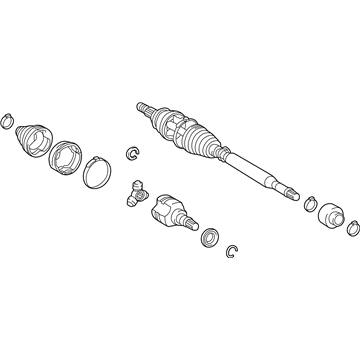

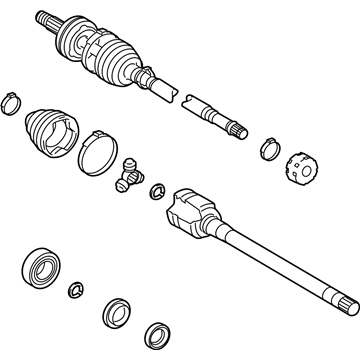

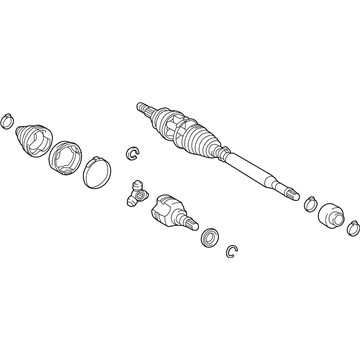

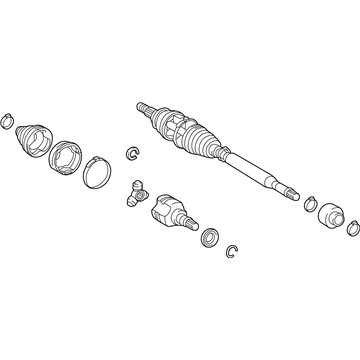

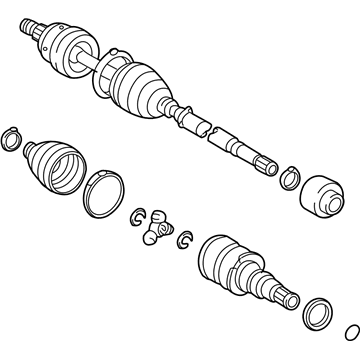

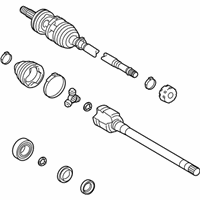

- Q: How to remove and replace the axle shaft assembly on Toyota Corolla?A:The first step in axle shaft assembly removal and replacement requires you to identify all components of the front drive shaft assembly used with the 2ZR-FE engine. You need to prepare all essential tools as well as parts needed for this procedure. The procedure demands proper detachment of the drive shaft through following the established guidelines which protect nearby components from harm. The new axle shaft assembly installation commences once the removal process ends by cleaning and tightening all connections with proper alignment.

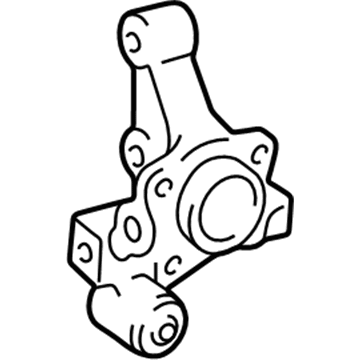

- Q: How to install the axle shaft assembly on Toyota Corolla?A:The installation of the 2ZR-FE front drive shaft assembly starts with placing new front drive shaft hole snap ring LH onto the front drive inboard joint assembly before you repeat the same steps for the RH side. You should put together the front drive shaft assembly LH by aligning its inboard joint splines while using a brass bar and hammer to install it correctly. This process requires the end gap of the front drive inboard joint hole snap ring to face downward toward the ground while keeping the oil seal and inboard joint boot safe from damage. Check the drive shaft installation by examining reaction forces together with sounds before repeating this procedure on the RH side. Insert the drive shaft spline into the front axle assembly LH by pushing the axle assembly from the vehicle while ensuring both minimal damage and less than needed slice of the outboard joint boot remains. Check the front Speed Sensor for alien material during this process. Repeat this for the RH side. The front lower suspension arms LH and RH installations must be followed by connecting the tie rod end sub-assemblies LH and RH before installing the front stabilizer link assemblies LH and RH. Performs the front speed sensor connection steps for both TMC Made and non-TMC Made versions while applying the same front-side procedures. The threaded drive shaft and front axle shaft nut components require cleaning with non-residue solvent before adding a new front axle shaft nut through a 30 mm socket wrench that should be tightened to 216 Nm (2203 kgf-cm, 160 ft-lbf) while sealing with a chisel and hammer on both sides. Perform the same procedure on the RH side before torquing front wheels to 103 Nm (1050 kgf-cm, 76 ft-lbf). Both transmission systems need the addition of manual transaxle oil for manuals and automatic transaxle fluid for auto transaxles before leak inspection begins. Under the engine cover both LH and RH inspect and align the front wheels properly while checking the VSC-enabled and VSC-disabled speed sensor signals.