×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota 4Runner Coil Springs

Strut Spring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

50 Coil Springs found

Toyota 4Runner Coil Spring, Driver Side

Part Number: 48131-35481$155.32 MSRP: $219.88You Save: $64.56 (30%)Ships in 1-3 Business Days

Toyota 4Runner Coil Spring, Passenger Side

Part Number: 48131-35590$88.74 MSRP: $124.57You Save: $35.83 (29%)Ships in 1-3 Business DaysToyota 4Runner Coil Spring, Passenger Side

Part Number: 48131-35501$105.57 MSRP: $148.19You Save: $42.62 (29%)Ships in 1-3 Business DaysToyota 4Runner Coil Spring, Driver Side

Part Number: 48131-35640$97.87 MSRP: $137.38You Save: $39.51 (29%)Ships in 1-3 Business DaysToyota 4Runner Coil Spring, Rear

Part Number: 48231-35370$133.70 MSRP: $189.28You Save: $55.58 (30%)Ships in 1-3 Business DaysToyota 4Runner Coil Spring, Rear

Part Number: 48231-35460$151.68 MSRP: $214.72You Save: $63.04 (30%)Ships in 1-3 Business DaysToyota 4Runner Coil Spring, Front

Part Number: 48131-35580$133.12 MSRP: $188.44You Save: $55.32 (30%)Ships in 1-3 Business DaysToyota 4Runner Coil Spring, Passenger Side

Part Number: 48131-35630$97.87 MSRP: $137.38You Save: $39.51 (29%)Ships in 1-3 Business DaysToyota 4Runner Coil Spring, Rear

Part Number: 48231-35340$118.43 MSRP: $167.65You Save: $49.22 (30%)Ships in 1-3 Business DaysToyota 4Runner Coil Spring, Rear

Part Number: 48231-35450$133.70 MSRP: $189.28You Save: $55.58 (30%)Ships in 1-3 Business DaysToyota 4Runner Coil Spring, Driver Side

Part Number: 48131-35340$158.07 MSRP: $223.78You Save: $65.71 (30%)Ships in 1-3 Business DaysToyota 4Runner Coil Spring, Rear

Part Number: 48231-35130$94.67 MSRP: $132.88You Save: $38.21 (29%)Ships in 1-2 Business Days

Toyota 4Runner Coil Spring, Passenger Side

Part Number: 48131-35511$106.76 MSRP: $149.85You Save: $43.09 (29%)Toyota 4Runner Coil Spring, Rear

Part Number: 48231-35350$121.25 MSRP: $171.64You Save: $50.39 (30%)

| Page 1 of 3 |Next >

1-20 of 50 Results

Toyota 4Runner Coil Springs

Choose genuine Coil Springs that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Coil Springs for your Toyota 4Runner? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota 4Runner parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota 4Runner Coil Springs Parts and Q&A

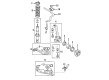

- Q: How to remove and inspect a coil springs and shock absorber on Toyota 4Runner?A:The coil spring should be removed while maintaining the rear axle housing in position with a jack and supporting the frame with stands. The first step involves removing the wheel by tightening it to 110 Nm (1,150 kgf-cm, 83 ft. lbs.). A 13 Nm (130 kgf-cm, 9 ft. lbs.) torque should be used to detach the parking brake cable bracket from the rear axle housing. You should disconnect the rear Shock Absorber by first applying 64 Nm (650 kgf-cm, 47 ft. lbs.) torque to remove the bolt and two washers and two bushings along with turning the shock absorber and holding the nut to pull out the three retainers and two cushions and the shock absorber with a torque of 20 Nm (200 kgf-cm, 14 ft. lbs.). Unfasten the stabilizer bar brackets while also separating the lateral control rod from the frame structure. Lower the rear axle housing while avoiding the brake line and take out the coil spring by ensuring correct positioning of the coil spring end. During inspection the shock absorber operation should be verified by pushing it while monitoring for smooth stroke pull with no unusual resistance or noise. Fully compress gas-filled shock absorbers to check the constant speed return after release; these types include engraved informational markings on the shell surface. Drilling a 2 - 3 mm (0.079 - 0.118 inch) hole at the correct location on a gas-filled shock absorber permits the gas release while chip debris should be handled carefully since the gas is colorless, odorless and contains no poisonous substances. Shock absorber installation follows the exact opposite steps of the removal process.

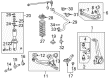

- Q: How to install the rear coil springs and connect the associated components on Toyota 4Runner?A:Start rear coil spring installation by putting the coil spring rear LH into the axle housing of the rear while positioning its lower end inside the spring lower seat gap. After installing the Shock Absorber assembly rear LH bolt you should first temporarily tighten it. Fully tighten the shock absorber assembly rear LH bolt to reach 98 Nm (1,000 kgf-cm, 72 ft-lbf) after stabilizing the suspension. Complete the connection of the rear brake tube flexible hose by installing 2 clips to the 2 flexible hoses and joining brake tubes to the flexible hose using a union nut wrench while tightening the components to 15 Nm (155 kgf-cm, 11 ft-lbf). You must add brake fluid to the reservoir before performing the brake line bleeding and checking the reservoir fluid level and inspecting for leakage of brake fluid. Install the rear wheel by tightening its bolts to 112 Nm (1,137 kgf-cm, 83 ft-lbf).