×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Valve Body

Trans Valve Body- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

21 Valve Bodies found

Toyota Valve Body

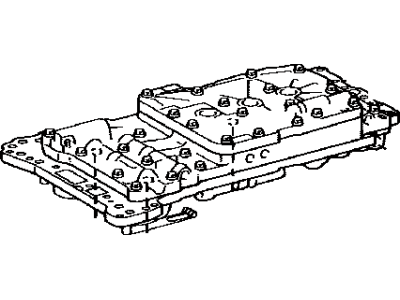

Part Number: 35410-0C070$926.83 MSRP: $1358.28You Save: $431.45 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Body Assembly, Transmission Valve

- Replaces: 35410-0C040, 35410-0C041

Toyota Valve Body

Part Number: 35410-0E010$952.82 MSRP: $1396.37You Save: $443.55 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Body Assembly, Transmission Valve

- Replaces: 35410-48100

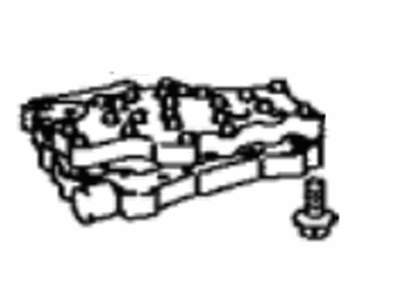

Toyota Body Assembly, Transmission Valve

Part Number: 35410-52290$923.20 MSRP: $1352.95You Save: $429.75 (32%)Ships in 1-3 Business DaysProduct Specifications- Manufacturer Note: AISIN AW:REF.ILLUST

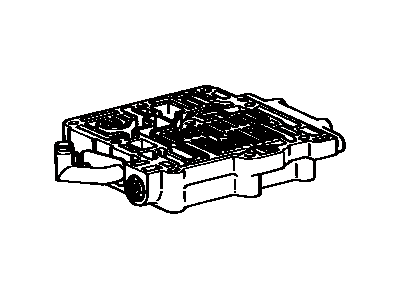

Toyota Valve Body

Part Number: 35410-WB002$1582.91 MSRP: $2319.76You Save: $736.85 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Body Assembly, Transmission Valve

- Replaces: 35410-WB003

Toyota Valve Body

Part Number: 35410-WAA02$3191.72 MSRP: $4677.51You Save: $1485.79 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Body Assembly, Transmission Valve

Toyota Valve Body

Part Number: 35400-0C090$1912.58 MSRP: $2802.90You Save: $890.32 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Body Assembly, Transmission Valve; Body Assembly, Transmission Valve W/Solenoid

Toyota Valve Body

Part Number: 35410-0R030$950.89 MSRP: $1393.54You Save: $442.65 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Body Assembly, Transmission Valve

- Manufacturer Note: TYPE B:REFER 35-01

- Replaces: 35410-48080

Toyota Valve Body

Part Number: 35410-60680$1018.76 MSRP: $1493.02You Save: $474.26 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Body Assembly, Transmission Valve

- Manufacturer Note: TYPE A:REFER 35-01

- Replaces: 35410-60590

Toyota Valve Body

Part Number: 35400-0C080$1501.83 MSRP: $2200.95You Save: $699.12 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: BODY ASSY, TRANSMISS; Body Assembly, Transmission Valve W/Solenoid

Toyota Valve Body

Part Number: 35410-12862$923.20 MSRP: $1352.95You Save: $429.75 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Body Assembly, Transmission Valve

- Manufacturer Note: AISIN AW:REF.ILLUST

Toyota Valve Body

Part Number: 35410-WAA01$3191.72 MSRP: $4677.51You Save: $1485.79 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Body Assembly, Transmission Valve

Toyota Body Assembly, Transmission Valve

Part Number: 35410-60650$925.01 MSRP: $1355.62You Save: $430.61 (32%)Ships in 1-3 Business DaysToyota Valve Body

Part Number: 35410-K0010$923.20 MSRP: $1352.95You Save: $429.75 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Body Assembly, Transmission Valve

- Replaces: 35410-12A30

Toyota Valve Body

Part Number: SU003-04328$1121.50 MSRP: $1528.56You Save: $407.06 (27%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Body Assembly, Valve; Body Assembly, Transmission Valve

Toyota Valve Body

Part Number: 35410-0R020$998.45 MSRP: $1463.24You Save: $464.79 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Body Assembly, Transmission Valve

- Replaces: 35410-48070

Toyota Body Assembly, Transmission Valve

Part Number: 35410-60660$971.78 MSRP: $1424.15You Save: $452.37 (32%)Ships in 1-3 Business DaysProduct Specifications- Replaces: 35410-0C051, 35410-35811, 35410-0C050, 35410-35810

Toyota Valve Body

Part Number: 35410-12871$687.36 MSRP: $1007.33You Save: $319.97 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Body Assembly, Transmission Valve

- Manufacturer Note: TMH:REFER TO ILLUST.

- Product Specifications

- Other Name: Body Assembly, Transmission Valve

- Manufacturer Note: TYPE B:REFER 35-01

- Product Specifications

- Other Name: Body Assembly, Transmission Valve

- Manufacturer Note: TMH:REFER TO ILLUST.

- Product Specifications

- Other Name: Body Assembly, Transmission Valve

| Page 1 of 2 |Next >

1-20 of 21 Results

Toyota Valve Body

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Toyota produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Toyota Valve Body? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

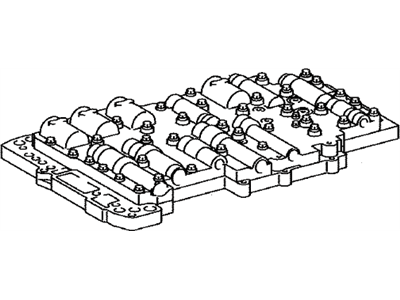

The Toyota Valve Body routes pressurized fluid quickly, providing automatic shifts with sharp timing and long-term confidence. Toyota has created a brand by reputation based on lean production lines that reduce wastage and maintain quality by trusting every employee to stop the production line to make corrections on the ground and give ideas on how to cut down a few seconds in time on each duty. All Toyota hybrids, such as small and SUV, demonstrate how the company balances fuel-saving and torque. Toyota also takes battery range to the next level, allowing daily commutes to be made with electrons and engines in storage, and it complements that with solid-state research that suggests even faster charging in the future. The faithful customers believe in Toyota since their vehicles shake off years of potholes, snow, and desert heat, and when they are neglected, they start on the first twist weeks later. The Valve Body has been installed within the automatic gearbox as the hydraulic command center, forcing fluid through complex channels, activating the clutch packs precisely at the speed and throttle-induced demand of a new ratio, so the gears slide into position without bumps on urban streets or rugged tracks. The Valve Body maintains transmission temperatures at a low level and ensures the life of the oil by real-time modulation of pressure. A coarse aluminum cover allows the Valve Body to shake off vibration and the dirty fluid, which would otherwise scar other castings. On demand of sudden power by drivers, the Valve Body opens snapping valves to allow torque to flow to wheels before hesitation builds up.

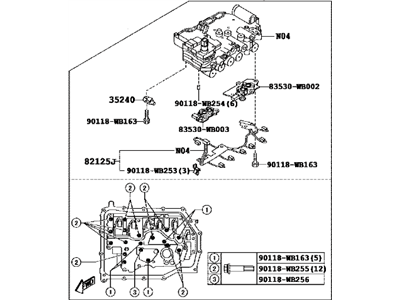

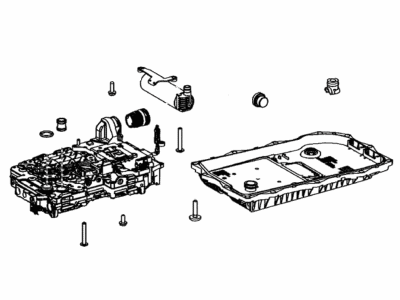

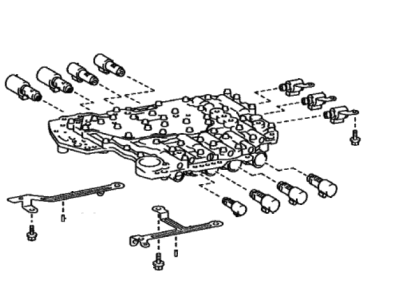

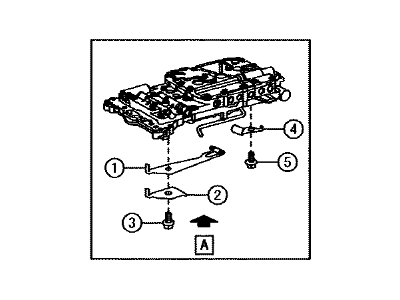

Toyota Valve Body Parts and Q&A

- Q: How to install the transmission valve body assembly on Toyota Sequoia?A:The manual valve lever receives the pin along with its hole for assembly while 19 bolts must be installed with 11 Nm (112 kgf-cm, 8 ft-lbf) torque; bolt A measures 36 mm (1.42 in.) while bolt B measures 25 mm (0.984 in.). Guide the installation of the detent spring cover together with the detent spring by using a bolt which requires a torque of 10 Nm (102 kgf-cm, 7 ft-lbf). The transmission wire must be connected then valve body oil strainer assembly needs installation before putting on the automatic transmission oil pan sub-assembly. Automatic transmission fluid installation and correct fluid level adjustment should follow the leak inspection procedure.

- Q: How to service and repair the valve body assembly on Toyota Tundra?A:The first step prior to servicing the valve body assembly is to disconnect the negative battery terminal cable but wait for at least 90 seconds after switching off the ignition so the navigation system can preserve its memory and system settings. Start the process by draining automatic transmission fluid before taking out the automatic transmission oil pan sub-assembly with the valve body oil strainer assembly. Activate the transmission valve body assembly removal process starting with cable removal then extraction of bolting, detent spring cover, detent spring alongside the 19 bolts from the valve body assembly before proceeding to separate the check ball body along with spring while maintaining careful prevention of dropping them. Follow the required procedures for shift solenoid valves SR, SLU, SL2, SLT, SL1, S1 and S2 to perform removal and check measurements of resistance and operational noise. The test results must meet specifications to avoid replacement of any solenoid valve. Follow the torque specifications while mounting shift solenoid valves S2, S1, SL1, SLT, SL2, SLU, and SR into their respective positions but apply ATF to new O-rings before installation. Complete installation of the transmission valve body by placing both spring and check ball body correctly then insert the manual valve pin followed by bolting it with 19 bolts while installing the detent spring cover and detent spring. Reinstall the transmission wire followed by valve body oil strainer assembly and automatic transmission oil pan sub-assembly, then reconnect the cable to the negative battery terminal before filling the transmission with fluid. Systems requiring initialization should be done after cable reconnection.