×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Tacoma Wheel Hub

Wheel Axle Hub- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Wheel Hubs found

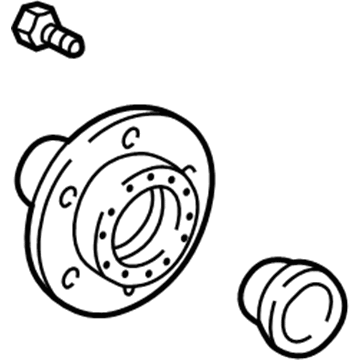

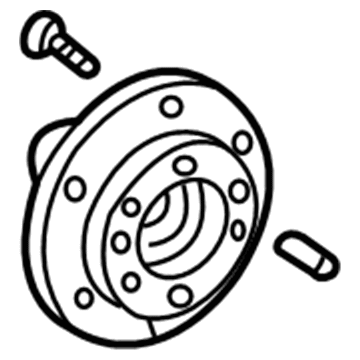

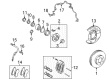

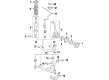

Toyota Tacoma Hub Assembly, Front

Part Number: 43502-35110$242.31 MSRP: $345.96You Save: $103.65 (30%)Ships in 1 Business Day

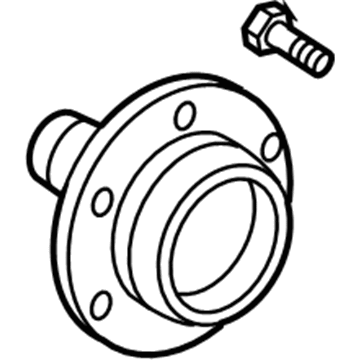

Toyota Tacoma Hub Assembly, Front

Part Number: 43502-60201$171.89 MSRP: $243.33You Save: $71.44 (30%)Ships in 1 Business Day

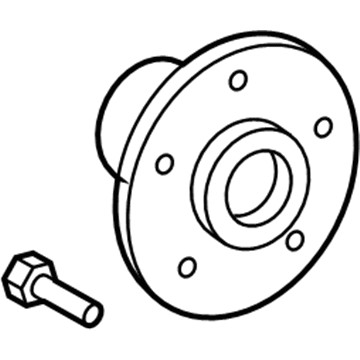

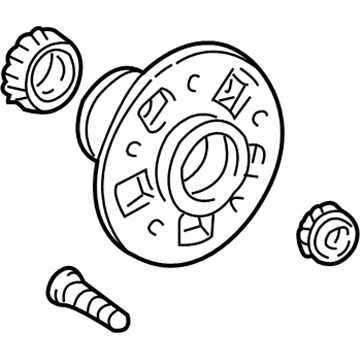

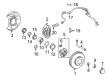

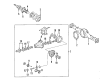

Toyota Tacoma Front Hub

Part Number: 43502-04112$173.07 MSRP: $245.00You Save: $71.93 (30%)Ships in 1-3 Business Days

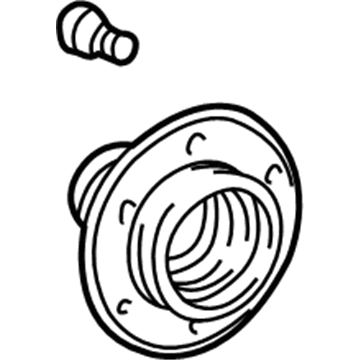

Toyota Tacoma Front Hub

Part Number: 43502-04080$165.31 MSRP: $234.02You Save: $68.71 (30%)Ships in 1-3 Business Days

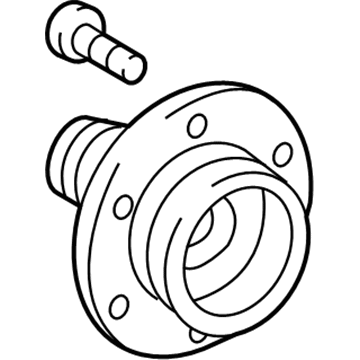

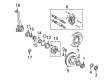

Toyota Tacoma Hub Assembly, Front

Part Number: 43502-35170$224.37 MSRP: $320.34You Save: $95.97 (30%)Ships in 1-2 Business Days

Toyota Tacoma Hub Assembly, Front

Part Number: 43502-35160$227.63 MSRP: $325.00You Save: $97.37 (30%)Ships in 1-2 Business Days

Toyota Tacoma Wheel Hub, Front

Part Number: 43502-04140$176.95 MSRP: $252.65You Save: $75.70 (30%)Ships in 1-3 Business Days

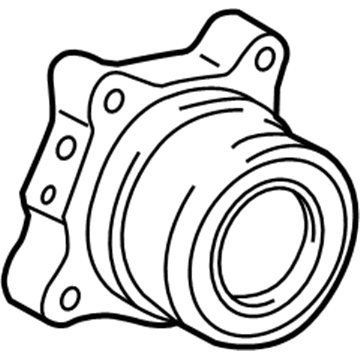

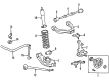

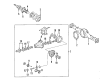

Toyota Tacoma Bearing Housing, Driver Side

Part Number: 42460-04010$356.15 MSRP: $521.95You Save: $165.80 (32%)

Toyota Tacoma Bearing Housing, Passenger Side

Part Number: 42450-04010$356.15 MSRP: $521.95You Save: $165.80 (32%)

Toyota Tacoma Wheel Hub

Choose genuine Wheel Hub that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Wheel Hub for your Toyota Tacoma? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Tacoma parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

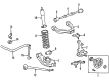

The Wheel Hub Assembly commonly known as WHA in Toyota Tacoma is an important part through which the wheels of a car revolve and at the same time fixed to the car properly. Specially, the splined teeth are applied to drive configurations and the roller bearings are applied to non-drive wheels to make sure the prime performance of vehicles. The right fixture and the correct torque to be applied is critical in avoiding mechanical breakdowns; SKF Wheel hub bearings were among the most frequently sold bearings in the market. The changes in layouts such as unit assemblies with ABS sensors and non-driven axle hubs with roller bearings are made in order to accommodate various vehicles, thus explaining the necessity of preserving wheel bearings for safety and efficacy.

Toyota Tacoma Wheel Hub Parts and Q&A

- Q: How to remove the front Wheel Hub on Toyota Tacoma?A:To withdraw the front axle assembly for 2WD vehicles follow both steps of disconnecting the battery negative cable then taking out the front tire. First you must disconnect both the skid control sensor wire and take out the Speed Sensor connector plus its two bolts. Take out the bolt to remove the front speed sensor. Break the front flexible hose connection by unscrewing its bolt. Following your removal of the Brake Caliper's flexible hose you can remove the brake caliper itself consisting of 2 bolts after you take out the union bolt and gasket. Unbolt the front disc while disconnecting the tie rod end sub-assembly by pulling out the cotter pin and nut then using Special Service Tool: 09610-20012 to split the tie rod end from the steering knuckle arm. Detach the front suspension lower arm through its 2 bolts to remove the front lower Ball Joint connection with the front axle. To remove the front suspension upper arm you must first disconnect its clip then bolt before detaching the upper ball joint from the steering knuckle using Special Service Tool: 09628-62011.

- Q: How to install the front Wheel Hub on Toyota Tacoma?A:Put the front axle hub in position first then apply a new nut to the front suspension upper arm but torque it to 110 Nm (1,122 kgf-cm, 81 ft-lbf) and add the clip ensuring correct hole placement otherwise adjust the nut with an additional 60 degrees. Begin with front suspension lower arm installation by fitting front lower ball joint LH to its receptacle using two bolts which require torquing at 160 Nm (1,631 kgf-cm, 118 ft-lbf). The installation process begins by attaching the tie rod end sub-assembly to the steering knuckle arm using a new nut which receives a torque of 49 Nm (500 kgf-cm, 36 ft-lbf). After this, the installation is finalized with a new cotter pin. When the holes do not align, additional tightening of the nut by 60 degrees is necessary. You must install the front disc and front disc Brake Caliper assembly with two bolts tightened to 108 Nm (1,101 kgf-cm, 80 ft-lbf). After this, apply a new gasket with a union bolt torqued to 30 Nm (306 kgf-cm, 22 ft-lbf) while making sure the flexible hose lock stays in the lock hole of the disc brake cylinder. The front Speed Sensor installation requires torque to 8.3 Nm (85 kgf-cm, 73 in-lbf) while keeping the sensor tip clean throughout the procedure. Fasten the speed sensor wire with two bolts that require torquing to 5.0 Nm (51 kgf-cm, 44 in-lbf) while connecting the speed sensor connector. Next, install the front wheel while tightening it to 113 Nm before connecting the cable to the negative battery terminal with 3.9 Nm. Brake fluid reservoir filling is required together with master cylinder bleeding followed by brake lines bleeding when necessary and fluid level checking at the reservoir with brake fluid leak inspection afterward VSC sensor signal inspection for equipped vehicles or ABS sensor signal inspection for non-equipped vehicles is followed by front wheel alignment inspection and adjustment.