×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Tacoma Wheel Bearing

Hub Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

17 Wheel Bearings found

Toyota Tacoma Wheel Bearing

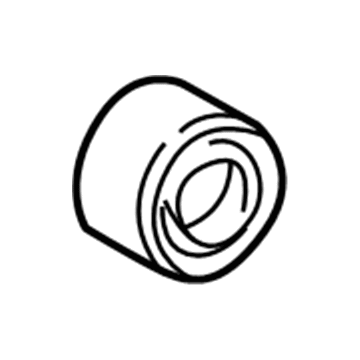

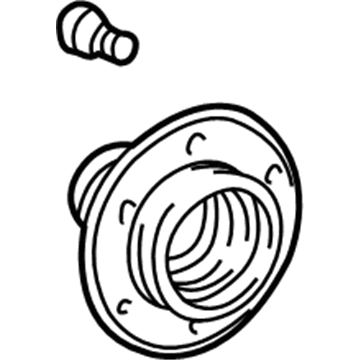

Part Number: 90369-54002$114.58 MSRP: $160.83You Save: $46.25 (29%)Ships in 1-3 Business Days

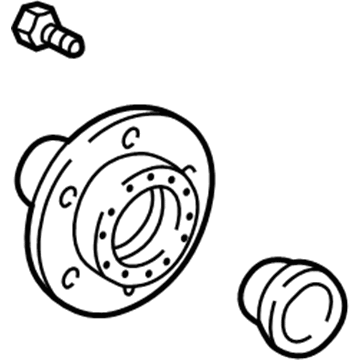

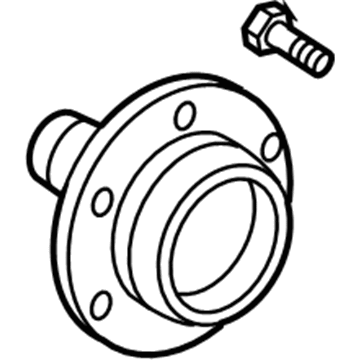

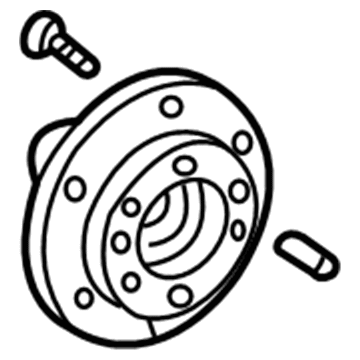

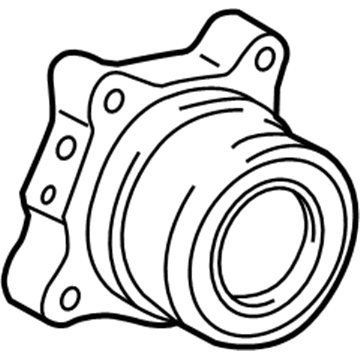

Toyota Tacoma Hub Assembly, Front

Part Number: 43502-35110$242.31 MSRP: $345.96You Save: $103.65 (30%)Ships in 1 Business Day

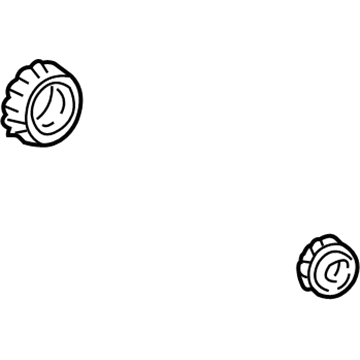

Toyota Tacoma Wheel Bearing

Part Number: 90366-A0001$87.44 MSRP: $122.74You Save: $35.30 (29%)Ships in 1 Business Day

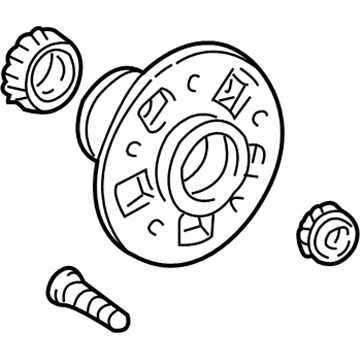

Toyota Tacoma Axle Bearings, Rear

Part Number: 90363-40068$75.00 MSRP: $105.27You Save: $30.27 (29%)Ships in 1-3 Business Days

Toyota Tacoma Wheel Bearing, Front

Part Number: 43570-04011$172.95 MSRP: $244.82You Save: $71.87 (30%)

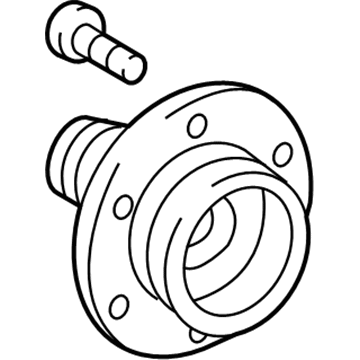

Toyota Tacoma Hub Assembly, Front

Part Number: 43502-60201$171.89 MSRP: $243.33You Save: $71.44 (30%)Ships in 1 Business Day

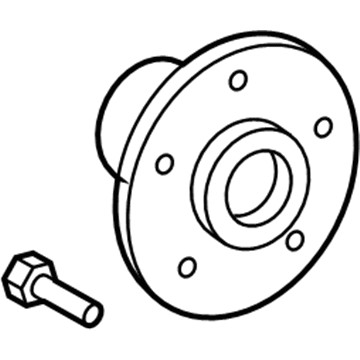

Toyota Tacoma Front Hub

Part Number: 43502-04112$173.07 MSRP: $245.00You Save: $71.93 (30%)Ships in 1-3 Business Days

Toyota Tacoma Front Hub

Part Number: 43502-04080$165.31 MSRP: $234.02You Save: $68.71 (30%)Ships in 1-3 Business Days

Toyota Tacoma Front Wheel Bearing

Part Number: 04421-35020$106.64 MSRP: $149.69You Save: $43.05 (29%)Ships in 1-3 Business Days

Toyota Tacoma Hub Assembly, Front

Part Number: 43502-35170$224.37 MSRP: $320.34You Save: $95.97 (30%)Ships in 1-2 Business Days

Toyota Tacoma Hub Assembly, Front

Part Number: 43502-35160$227.63 MSRP: $325.00You Save: $97.37 (30%)Ships in 1-2 Business Days

Toyota Tacoma Wheel Hub, Front

Part Number: 43502-04140$176.95 MSRP: $252.65You Save: $75.70 (30%)Ships in 1-3 Business Days

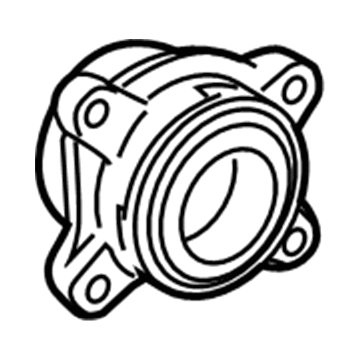

Toyota Tacoma Bearing Housing, Driver Side

Part Number: 42460-04010$356.15 MSRP: $521.95You Save: $165.80 (32%)

Toyota Tacoma Bearing Housing, Passenger Side

Part Number: 42450-04010$356.15 MSRP: $521.95You Save: $165.80 (32%)

Toyota Tacoma Wheel Bearing

Choose genuine Wheel Bearing that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Wheel Bearing for your Toyota Tacoma? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Tacoma parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

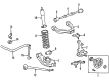

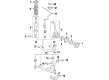

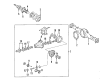

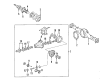

The Wheel Bearing used in Toyota Tacoma vehicles has the responsibility of holding and supporting the wheels to rotate in an efficient manner thereby increasing the performance and safety of the vehicle. These bearings, which are housed in the hubs, reduce some of the friction so that the wheel and tyre assembly is able to rotate. Through the year, Tacoma models have used many kinds of hub and bearings such as the unit or integral hub and bearing assembly that may contain the ABS sensor and replaced as a whole unit. Moreover, a number of models can be equipped with non-driven axle hubs equipped with replaceable tapered roller bearings. Defective or worn wheel bearings, can causes such things as noise, vibration and in some extreme cases, the separation of wheels from their respective vehicles hence should be inspected frequently. Some of the tests that may be carried out in order to determine the health of these bearings include the following - rotating of the wheel and feeling for roughness along with examination of the hub after the removal of the brake components.

Toyota Tacoma Wheel Bearing Parts and Q&A

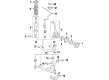

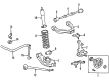

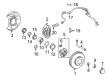

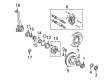

- Q: How to Service and Repair a Wheel Bearing on Toyota Tacoma?A:Start wheel bearing servicing by taking off the front wheel from the vehicle. Vehicles with ABS require removal of the 2 bolts connecting the ABS speed sensor wire harness clamp to the steering knuckle. Disconnection of the Brake Caliper commences after removing the 2 bolts while securely supporting the component. Measure the backlash of the bearing shaft direction with a dial indicator after removing the grease cap using a screwdriver; replace the axle hub bearing when the measurement reaches more than 0.05 mm (0.0020 inch). Start by extracting the axle hub with the disc through a process that includes removing the cotter pin and lock cap followed by using a 30 mm socket wrench to take off the nut before separating the claw washer along with outer bearing and axle hub with disc from the steering knuckle with extreme caution regarding the outer bearing drop. A screwdriver can be used to remove the oil seal while protecting the ABS speed sensor rotor. Extract the inner bearing from the axle hub. The installation begins by removing 4 dust cover bolts and thereafter breaking the stabilizer bar link with tool assistance then disassembling the nut followed by five retainers and a collar with four cushions and bolt components. Before separation place a jack under the lower suspension arm and remove its two lower Ball Joint set bolts and cotter pin and nut. Use Special Service Tool: 09628-62011 to disconnect the steering knuckle from the upper ball joint before you remove the 2 lower ball joint set bolts, the nut and steering knuckle while keeping the jack in position. To install the part you should first support the lower suspension arm with a jack before placing the steering knuckle onto the lower ball joint and temporarily securing it with the 2 bolts. After pushing down the upper suspension arm to join the upper ball joint with the steering knuckle fasten the nut while torquing it to 110 Nm (1,100 kgf-cm, 80 ft. lbs.) then install a new cotter pin and tighten the nut an extra 60 degrees when the cotter pin holes are misaligned. Place the dust cover onto its mounting bracket and bolt it in with 4 fasteners at 8.3 Nm (85 kgf-cm, 74 inch lbs.). Position the stabilizer bar link onto the bolt from which you will mount five retainers and a collar and four cushions and a new nut. Apply MP grease into your palm to stuff it within the bearing until the product leaks out through the opposing side while making sure to completely cover the complete bearing surface. Apply MP grease inside the hub chamber and cap before inserting the inner bearing into the axle hub. The procedure for installing a new oil seal into the axle hub requires Special Service Tools: 09527-17011, 09950-60020 (09951-00710), 09950-70010 (09951-07150) and a hammer while being careful to avoid damaging the ABS speed sensor rotor and applying MP grease to the oil seal lip. The spindle should receive the axle hub along with a new outer bearing which has a claw washer. Adjust the preload through several steps using a spring tension gauge and the specified value of frictional force plus 6-18 N (0.6-1.8 kgf, 1.3-4.0 lbs.). Begin by installing the nut to 34 Nm (350 kgf-cm, 25 ft. lbs.), turn the hub several times to achieve smoothness, loosen the nut until hand-turning is possible and measure the frictional force of the oil seal. Ensure the preload stays within the specified value. After achieving the desired preload you must use a dial indicator to check bearing shaft backlash while making sure the measurement stays below 0.05 mm (0.0020 inch). Position the lock cap followed by a fresh cotter pin and apply an additional 60 degrees of torque on the nut only if you encounter misalignment of the holes. Finish by securing the grease cap. The brake caliper should be installed with its two bolts torqued to 108 Nm (1,100 kgf-cm, 80 ft. lbs.) followed by attaching vehicles with ABS through the ABS speed sensor and wire harness clamp using two bolts torqued to 8.0 Nm (82 kgf-cm, 71 inch lbs.). The front wheel installation requires a torque of 110 Nm (1,150 kgf-cm, 83 ft. lbs.) before testing the brake pedal multiple times and inspecting the wheel alignment along with validating the ABS speed sensor signal.