×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Tacoma Yaw Sensor

Yaw Rate Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Yaw Sensors found

Toyota Tacoma Yaw Rate Sensor, Front

Part Number: 89183-60020$297.93 MSRP: $365.37You Save: $67.44 (19%)Ships in 1-3 Business Days

Toyota Tacoma Yaw Rate Sensor

Part Number: 89183-48030$287.32 MSRP: $352.37You Save: $65.05 (19%)Ships in 1-3 Business Days

Toyota Tacoma Yaw Sensor

Choose genuine Yaw Sensor that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Yaw Sensor for your Toyota Tacoma? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Tacoma parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

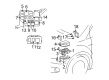

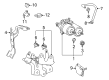

Toyota Tacoma Yaw Sensor Parts and Q&A

- Q: How to install the Yaw Sensor on Toyota Tacoma?A:A properly installed Yaw Rate Sensor for VSC vehicles requires 2 bolts which need to be tightened to a torque of 13 Nm (127 kgf-cm, 9 ft-lbf) while maintaining correct sensor angle. The next procedure requires connecting the yaw rate sensor connector. Pursue the installation of the sensor bracket by using a bolt secured with 13 Nm of torque (127 kgf-cm or 9 ft-lbf) before clamping the wire harness. Install the cowl side trim board for Regular Cab, Access Cab, Double Cab lineups before installing front door scuff plates on a per-cab basis. Place the front floor footrest along with the Bench Seat Type's front seat assembly and front seat headrest assembly of the same kind. The installation of front seat inner belt assemblies should be conducted for the left and right sides of the Bench Seat Type. The front seat assembly and seat track cover installation steps belong to the Separate Seat Type procedure. To complete installation connect the cable to the negative battery terminal using a torque of 3.9 Nm (40 kgf-cm, 35 in-lbf) while conducting the yaw rate sensor zero point calibration as well as testing the VSC sensor signal.