×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

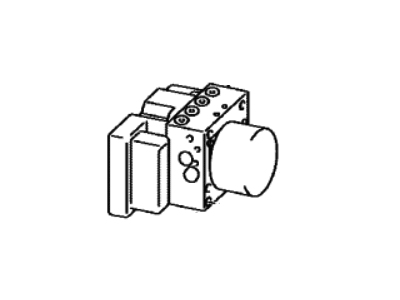

OEM Toyota RAV4 ABS Control Module

Anti Lock Brake Control Module- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

67 ABS Control Modules found

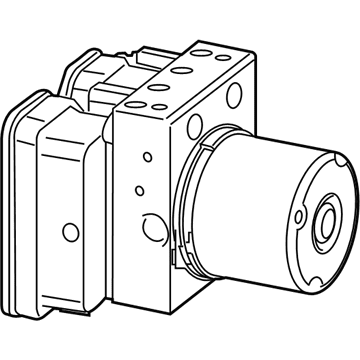

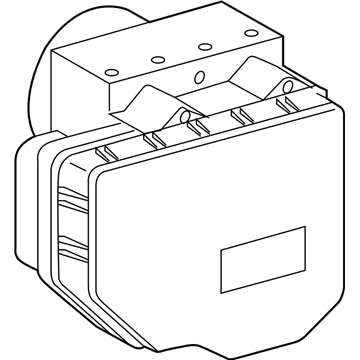

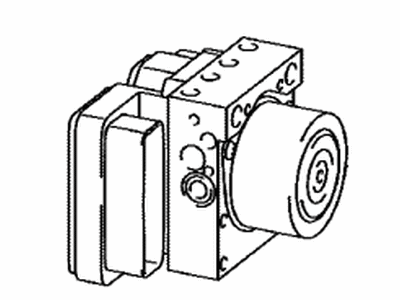

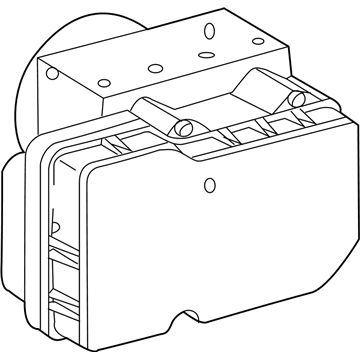

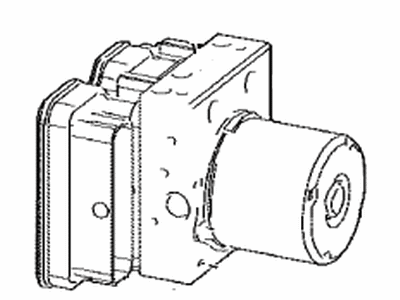

Toyota RAV4 Modulator Valve

Part Number: 44050-42F30$836.71 MSRP: $1053.26You Save: $216.55 (21%)Ships in 1-3 Business DaysToyota RAV4 Actuator Assembly

Part Number: 44050-42D40$880.52 MSRP: $1108.41You Save: $227.89 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-0R390$899.25 MSRP: $1131.98You Save: $232.73 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-42F61$1006.96 MSRP: $1267.57You Save: $260.61 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-42520$880.52 MSRP: $1108.41You Save: $227.89 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-42412$965.65 MSRP: $1215.57You Save: $249.92 (21%)Ships in 1-3 Business DaysToyota RAV4 Actuator Assembly

Part Number: 44050-42P20$912.55 MSRP: $1148.73You Save: $236.18 (21%)Ships in 1-2 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-0R152$916.61 MSRP: $1153.84You Save: $237.23 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-42C91$999.70 MSRP: $1258.43You Save: $258.73 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-42780$999.70 MSRP: $1258.43You Save: $258.73 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-42C90$848.79 MSRP: $1068.46You Save: $219.67 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-0R590$829.56 MSRP: $1044.25You Save: $214.69 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-42B21$999.70 MSRP: $1258.43You Save: $258.73 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-0R170$899.70 MSRP: $1132.55You Save: $232.85 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-42M30$855.55 MSRP: $1076.97You Save: $221.42 (21%)Ships in 1-3 Business DaysToyota RAV4 Actuator Assembly

Part Number: 44050-42D00$848.79 MSRP: $1068.46You Save: $219.67 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-0R064$965.65 MSRP: $1215.57You Save: $249.92 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-42B50$999.70 MSRP: $1258.43You Save: $258.73 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-42F31$1006.96 MSRP: $1267.57You Save: $260.61 (21%)Ships in 1-3 Business DaysToyota RAV4 Modulator Valve

Part Number: 44050-0R400$965.65 MSRP: $1215.57You Save: $249.92 (21%)Ships in 1-3 Business Days

| Page 1 of 4 |Next >

1-20 of 67 Results

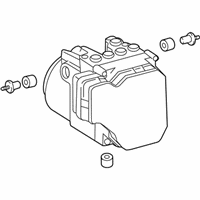

Toyota RAV4 ABS Control Module

Choose genuine ABS Control Module that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM ABS Control Module for your Toyota RAV4? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota RAV4 parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota RAV4 ABS Control Module Parts and Q&A

- Q: How to remove the ABS Control Module for Antilock Brakes on Toyota RAV4?A:Begin the Hydraulic Control Assembly for Antilock Brakes removal process by disconnecting the negative cable battery terminal then waiting 90 seconds to avoid activating Air Bag and seat belt pretensioners. To access the air cleaner case of the 2AZ-FE engine you should perform the maintenance steps which start with purge VSV removal and culminate in the air cleaner case removal. The air cleaner case removal process for 2GR-FE units should begin by following the same procedure from air cleaner cap sub-assembly removal until it reaches the air cleaner case. The draining process for brake fluid should be followed by urgency to wash away fluid from painted areas. The service technician should detach each of the 6 Brake Lines from the actuator with Special Service Tool: 09023-00101 while tagging the installation spots on the lines. The procedure ends with removing the ABS and traction actuator assembly with bracket where you first disconnect the connector through the lock lever upward movement then remove the brake tube clamp from the bracket followed by taking off 3 nuts and removing the actuator and bracket while handling brake tubes with caution.

- Q: How to install the ABS Control Module with the brake actuator and bracket on Toyota RAV4?A:Before installing the brake actuator together with its bracket you must keep the hole plug inside until completing the brake tube connection because new brake actuators contain brake fluid. Three nuts require a 19 Nm (194 kgf-cm, 14 ft-lbf) torque for installation of the actuator with bracket. It is essential to tighten the nuts in alphabetical order yet maintain proper care for the brake tubes and to avoid dropping the actuator with a mandatory replacement if it does get dropped. Begin by adding the brake tube clamp to the bracket; then correctly position all Brake Lines on the actuator before connecting them with a 10 mm union nut wrench at 15 Nm torque (155 kgf-cm, 11 ft-lbf) wrench-free or 14 Nm (145 kgf-cm, 10 ft-lbf) with wrench support while maintaining a 300 mm (11.8 in.) torque wrench fulcrum at 90 degrees from the union nut wrench. The procedure starts by attaching the connector then lowering the lock lever while performing fluid addition to the reservoir followed by bleeding air through the Brake Master Cylinder and brake lines and ABS and traction actuator assembly before checking the fluid level and inspecting for leaks. The assembly process includes adding the air cleaner case sub-assembly for both 2AR-FE and 2GR-FE engines. Prior to checking the ABS and traction actuator assembly with Techstream you must connect the cable to the negative battery terminal.