×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Prius Knock Sensor

Engine Knock Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Knock Sensors found

Toyota Prius Knock Sensor

Part Number: 89615-06010$138.05 MSRP: $195.42You Save: $57.37 (30%)Ships in 1-3 Business Days

Toyota Prius Knock Sensor

Part Number: 89615-52010$152.39 MSRP: $215.72You Save: $63.33 (30%)Ships in 1 Business Day

Toyota Prius Knock Sensor

Choose genuine Knock Sensor that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Knock Sensor for your Toyota Prius? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Prius parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

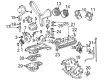

Toyota Prius Knock Sensor Parts and Q&A

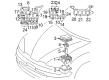

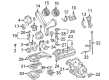

- Q: How to install the knock sensor and related components on Toyota Prius?A:Secure the knock sensor with the nut following correct orientation before torquing to 20 Nm (204 kgf-cm, 15 ft-lbf). After securely attaching the knock sensor connector will be the next step. For installing the intake manifold you should apply a new gasket onto the cylinder head before bolting the manifold into position using 3 bolts and 2 nuts which need a torque setting of 20 Nm (204 kgf-cm, 15 ft-lbf). The process starts by fixing the No. 1 fuel vapor feed hose to its clamp followed by attaching the harness clamp bracket with a 9.0 Nm (92 kgf-cm, 80 in-lbf) bolt torque before adding connector clamps and three wire harness clamps. Reconnect all the mounting cables beginning with the Throttle Position Sensor along with the throttle control motor and ending with the No. 2 water by-pass hose and water by-pass hose and No. 1 fuel vapor feed hose and No. 2 ventilation hose and ventilation hose. The oil dipstick guide needs a new O-ring smeared with thin engine oil before bolt installation with 9.0 Nm (92 kgf-cm, 80 in-lbf) torque while checking for cracked or jammed O-ring condition. Fasten the wire harness clamp while installing the dipstick into position. Once the air cleaner assembly fits into place, reconnect the negative battery terminal cable then add coolant through inspection of any possible leakage. The engine should be installed beneath the LH under cover alongside the radiator support opening cover. Part of the procedure requires running initialization sequences because systems need it after battery lead cable disconnect and reconnect at the negative (-) terminal.