×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Land Cruiser A/C Clutch

Air Conditioning Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 A/C Clutches found

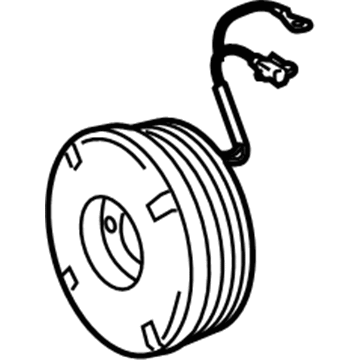

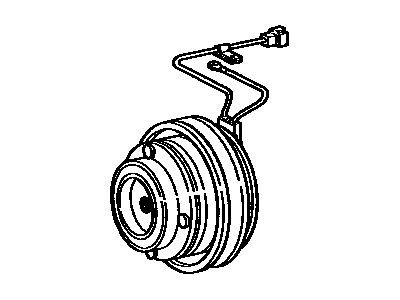

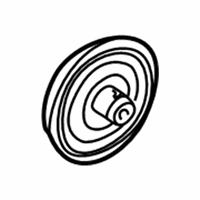

Toyota Land Cruiser Clutch Assembly, Magnet

Part Number: 88410-6A090$143.46 MSRP: $203.08You Save: $59.62 (30%)Ships in 1-3 Business Days

Toyota Land Cruiser Clutch Assembly, Magnet

Part Number: 88410-60410$144.28 MSRP: $204.25You Save: $59.97 (30%)Ships in 1-3 Business Days

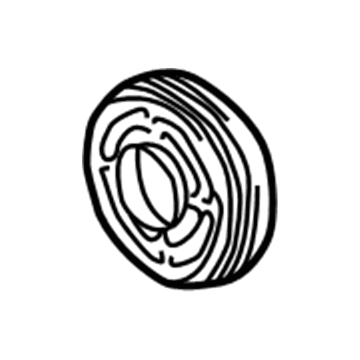

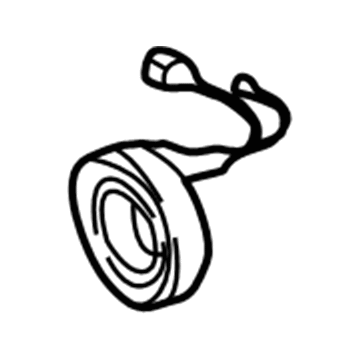

Toyota Land Cruiser Rotor

Part Number: 88412-60070$346.10 MSRP: $507.20You Save: $161.10 (32%)Ships in 1-3 Business DaysToyota Land Cruiser Clutch Assembly, Magnet

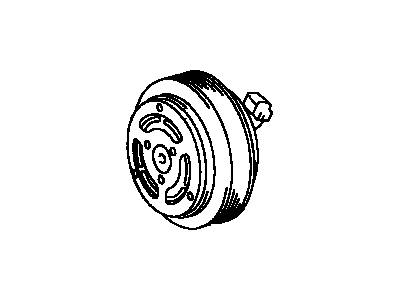

Part Number: 88410-0C140$486.11 MSRP: $712.40You Save: $226.29 (32%)Ships in 1-3 Business Days

Toyota Land Cruiser A/C Clutch

Choose genuine A/C Clutch that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM A/C Clutch for your Toyota Land Cruiser? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Land Cruiser parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

One of the lessor known but critically important components in the A/C system is the Toyota Land Cruiser A/C Clutch commonly used in the A/C systems of numerous Land Cruiser models. This A/C Clutch effectively couples the engine energy to power the A/C compressor whenever the functionality of A/C is on. Its design is such that it ceases to bear the load at the time when not needed to thus help conserve fuel and support improved performance of the engine. Toyota Land Cruiser A/C Clutch is versatile and supports various gene- erations of the Toyota Land Cruiser vehicles so that the owners regardless of the generation can control the climate of the car perfectly. This compatibility shows Toyota's dedication to providing good quality and innovative product such as the A/C Clutch designed to meet the challenges ahead of it such as high temperature and rough terrains on Land Cruiser cars. The Toyota Land Cruiser A/C Clutch has several peculiarities: its design is rather robust and it is less susceptible to such problems as sticking and slipping, providing the A/C is constantly operating efficiently and the overall lifespan of the compressor is increased. Thus, the A/C Clutch remains central to properly running a vehicle and makes a significant contribution to passengers' comfort and safety. In summary, the Toyota Land Cruiser A/C Clutch has ranked very well in numerous qualities that make a car component unique and deserving of a space in the market today; especially in the area of reliability, efficacy and compatibility; and for this reason it is highly recommended for any Land Cruiser user who would like to keep his or her car's performance and comfort levels optimal.

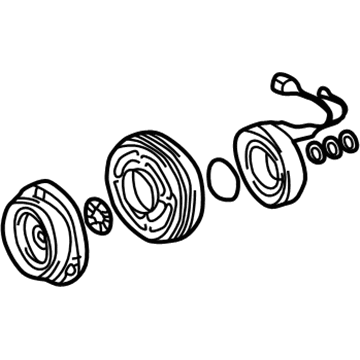

Toyota Land Cruiser A/C Clutch Parts and Q&A

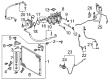

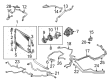

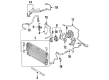

- Q: How to service and repair the A/C Clutch on Toyota Land Cruiser?A:Start the compressor clutch service by performing the disassembly procedure. Start the task by taking out the pressure plate through combination use of Special Service Tool: 07112-76060 along with a socket wrench on the shaft bolt and maintaining the torque at 13.2 N.m (135 kgf.cm, 9 ft.lbf). The pressure plate removal procedure requires Special Service Tool: 07112-66040 together with Special Service Tool: 07112-76060 along with a socket wrench for successful completion. After using these tools to remove the pressure plate, extract the shims. Special Service Tool: 95994-10020 should be used to disassemble the snap ring while rotor removal until the beveled side becomes visible for reinstallation purposes. A plastic hammer should be used to gently tap the rotor off the shaft while keeping the pulley safe from damage. The procedure for removing the stator requires the stator lead wire disconnection from the compressor housing followed by snap ring detachment using Special Service Tool: 95994-10020 with the snap ring beveled side oriented upward for subsequent reassembly. Reassembly happens in the reverse direction when compared to disassembly. The dial indicator should be mounted onto the pressure plate to check magnetic clutch clearance while linking the magnetic clutch lead wire to the positive (+) battery terminal. During battery terminal connection apply negative (-) power and verify the pressure plate-rotor gap lies between 0.5 and 0.15 mm (0.020 and 0.0059 in.). The adjustment of clearance requires shims with three options: 0.1 mm (0.004 in.), 0.3 mm (0.012 in.), and 0.5 mm (0.020 in.) to reach the standard clearance.

- Q: How to remove and replace the A/C Clutch on Toyota Land Cruiser?A:Starting the process of compressor and magnetic clutch removal requires disconnecting the negative battery terminal cable followed by at least 90 seconds of waiting to deactivate Air Bags and seat belt pretensioners. Start by discharging the refrigerant from the refrigeration system and then proceed to remove engine under cover and Drive Belt. Open the discharge and suction hoses by unfastening their 2 bolts and protect the openings with vinyl tape to avoid moisture and foreign matter contamination. Disconnect the connector followed by removal of three bolts to extricate the cooler compressor assembly after disconnection of the front Drive Shaft LH. Begin installation by inserting the cooler compressor assembly through its 3 bolts using torque of 49 N.m (500 kgf.cm, 36 ft.lbf) before reconnecting the connector. Start by installing the front drive shaft LH and then apply compressor oil (ND-OIL 8 or equivalent) to new O-rings as well as the hoses' fitting surfaces before using the 2 bolts to connect discharge and suction hoses after immediately removing both caps. After installing the drive belt users must reconnect to the negative battery terminal while performing initialization since the systems will need initialization after cable reconnecting. A refrigerant charge must be conducted after the machine receives a proper warm-up period followed by a comprehensive refrigerant leak detection process.