×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Echo Wheel Bearing

Hub Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Wheel Bearings found

Toyota Echo Front Wheel Bearing

Part Number: 90369-38021$115.64 MSRP: $162.33You Save: $46.69 (29%)Ships in 1-2 Business Days

Toyota Echo Front Hub

Part Number: 43502-52010$126.07 MSRP: $178.46You Save: $52.39 (30%)Ships in 1-2 Business Days

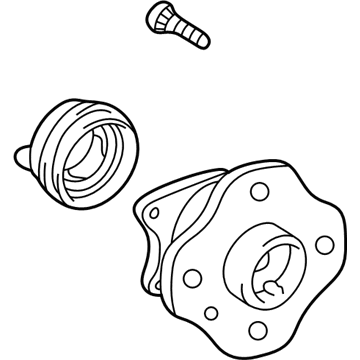

Toyota Echo Hub Assembly

Part Number: 42410-52021$226.46 MSRP: $323.34You Save: $96.88 (30%)Ships in 1-3 Business Days

Toyota Echo Hub Assembly, Rear

Part Number: 42450-52021$393.61 MSRP: $576.83You Save: $183.22 (32%)Ships in 1-3 Business Days

Toyota Echo Wheel Bearing

Choose genuine Wheel Bearing that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Wheel Bearing for your Toyota Echo? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Echo parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Echo Wheel Bearing Parts and Q&A

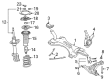

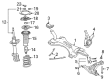

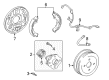

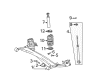

- Q: How to Service and Repair a Wheel Bearing on Toyota Echo?A:You should begin the wheel bearing service and repair work by taking off the front wheel. Check the bearing backlash together with axle hub deviation by removing the Brake Caliper and disc assembly which allows secure support for the brake caliper assembly. Inspection with the dial indicator at the hub axle center requires backlash measurement which should be under 0.05 mm (0.0020 inch) or a bearing replacement becomes necessary. The measurement of axle hub deviation on the hub surface area outside the bolt must be below 0.05 mm (0.0020 inch) while hub axle replacement could be necessary. Reinstall the brake caliper then secure it and put back the disc with the two bolts torqued to 88 Nm (900 kgf.cm, 65 ft. lbs.). Apply Special Service Tool: 09930-00010 and a hammer to unstake the lock nut before removing it while applying brakes. Uninstall the brake caliper with 2 bolts and disc while securely supporting the brake caliper position. The ABS speed sensor bolt needs removal during disconnection when ABS is installed on the vehicle. You must disconnect the steering knuckle from the lower suspension arm by removing its clip and nut before using Special Service Tool: 09628-00011 (09628-00030, 09628-00040, 09628-00050) to proceed with the disconnect. Use Special Service Tool: 09628-62011 to disconnect the tie rod end following tie rod end removal from the steering knuckle after breaking the nuts and cotter pin. The Shock Absorber operation needs the removal of two nuts and bolts together with the axle hub and steering knuckle while avoiding damage to the boot and ABS speed sensor rotor. Begin by putting the steering knuckle along with axle hub onto the shock absorber before applying engine oil to the threads of the 2 nuts and installing them at the shock absorber's lower side using a torque of 132 Nm (1,350 kgf.cm, 97 ft. lbs.). The tie rod end should be connected to the steering knuckle by using a nut followed by a 49 Nm (500 kgf.cm, 36 ft. lbs.) tightening torque, then adding a new cotter pin and enhancing the torque when holes for the pin do not match. The lower suspension arm through the nut connects with the steering knuckle after torquing to 98 Nm (1,000 kgf.cm, 72 ft. lbs.). A new clip receives installation following this nut tightening to 60 degrees when the holes for the clip are misaligned. Install the ABS speed sensor only if your vehicle has this feature by torqueing it at 8.0 Nm (82 kgf.cm, 71 inch lbs.). First install the disc along with the brake caliper and two bolts together, finally torque them to 88 Nm (900 kgf.cm, 65 ft. lbs.). Then install a new lock nut under brake application torque it to 216 Nm (2,200 kgf.cm, 159 ft. lbs.) before using a chisel and hammer to stake the lock nut. Recheck bearing backlash then install the front wheel and torque it to 103 Nm (1,050 kgf.cm, 76 ft. lbs.). Perform several brake pedal depressions before inspecting front wheel alignment along with checking the ABS speed sensor signal if the vehicle is equipped with this system.