×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Corolla Clutch Slave Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Clutch Slave Cylinders found

Toyota Corolla Slave Cylinder

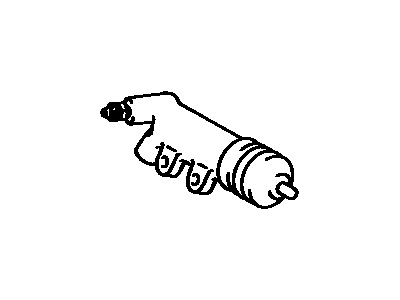

Part Number: 31470-12140$73.34 MSRP: $102.94You Save: $29.60 (29%)Ships in 1-3 Business Days

Toyota Corolla Slave Cylinder

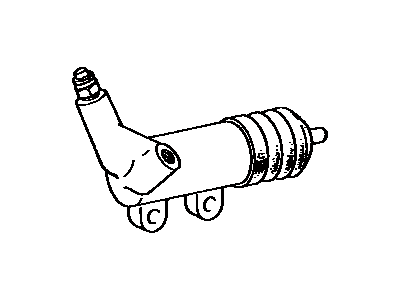

Part Number: 31470-42040$93.01 MSRP: $130.55You Save: $37.54 (29%)Ships in 1-3 Business Days

Toyota Corolla Slave Cylinder

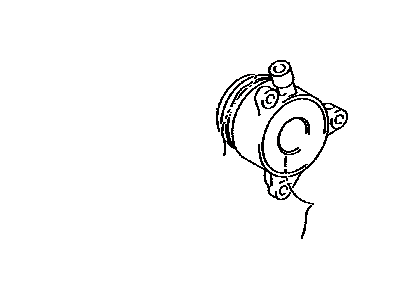

Part Number: 31470-12161$66.82 MSRP: $93.80You Save: $26.98 (29%)Ships in 1-3 Business Days

Toyota Corolla Slave Cylinder

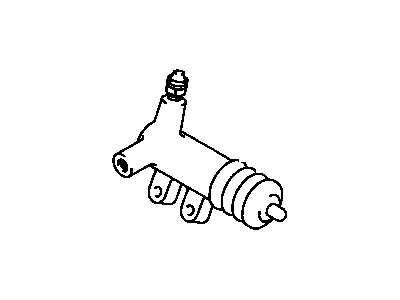

Part Number: 31470-12130$105.33 MSRP: $147.85You Save: $42.52 (29%)Ships in 1-3 Business Days

Toyota Corolla Slave Cylinder

Part Number: 31470-12050$82.70 MSRP: $116.09You Save: $33.39 (29%)Ships in 1-3 Business DaysToyota Corolla Slave Cylinder

Part Number: 31470-32023$73.58 MSRP: $103.28You Save: $29.70 (29%)Ships in 1-3 Business DaysToyota Corolla Slave Cylinder

Part Number: 31400-59025$195.24 MSRP: $278.77You Save: $83.53 (30%)Ships in 1-3 Business Days

Toyota Corolla Clutch Slave Cylinder

Choose genuine Clutch Slave Cylinder that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Clutch Slave Cylinder for your Toyota Corolla? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Corolla parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Corolla Clutch Slave Cylinder Parts and Q&A

- Q: How to remove the Clutch Slave Cylinder on Toyota Corolla?A:The first step to disconnect the Clutch Release Cylinder (for C59) involves using a union nut wrench (10 mm) to detach the clutch line into a catching container for fluid. First disconnect the clutch tube bracket through removing two bolts and then separate the clutch release cylinder with its two retaining bolts.

- Q: How to install the Clutch Slave Cylinder assembly on Toyota Corolla?A:Begin the clutch release cylinder installation by fastening it with the provided 2 bolts which must reach a minimum torque of 12 Nm (120 kgf-cm, 9 ft-lbf). The installation process requires attaching the clutch tube bracket through two bolts that need 12 Nm (122 kgf-cm, 9 ft-lbf) torque setting for Bolt A and 8.0 Nm (82 kgf-cm, 71 in-lbf) for Bolt B. The clutch line requires a union nut wrench (10 mm) with a torque of 15 Nm (155 kgf-cm, 11 ft-lbf) unless using the wrench for which the torque needs to be set at 14 Nm (143 kgf-cm, 10 ft-lbf). The unfolding torque wrench must have 250 mm (9.84 in.) fulcrum length while maintaining parallel alignment of the union nut wrench with the torque tool for precise torque measurements. After installation the brake fluid reservoir needs to be filled and the clutch line requires bleeding followed by inspection of fluid level and identification of clutch system leaks.