×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Corolla Pressure Plate

Clutch Pressure Plate- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Pressure Plates found

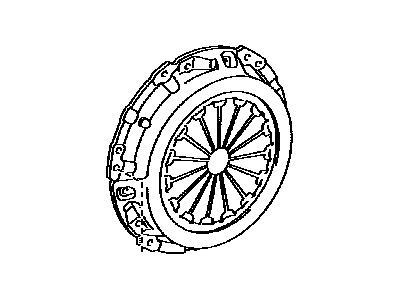

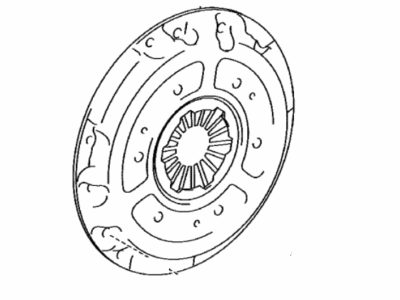

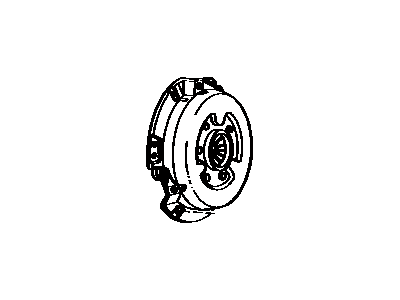

Toyota Corolla Pressure Plate

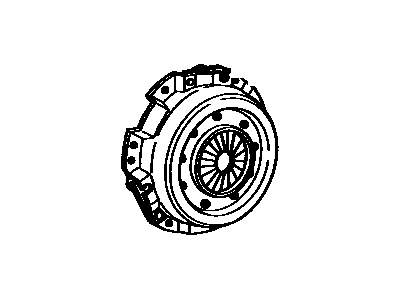

Part Number: 31210-12291$145.34 MSRP: $205.74You Save: $60.40 (30%)Ships in 1-3 Business Days

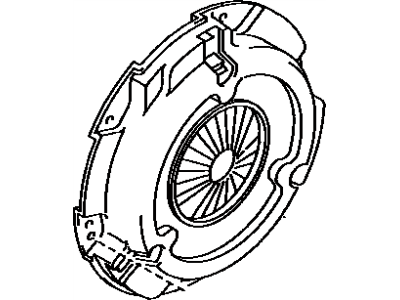

Toyota Corolla Pressure Plate

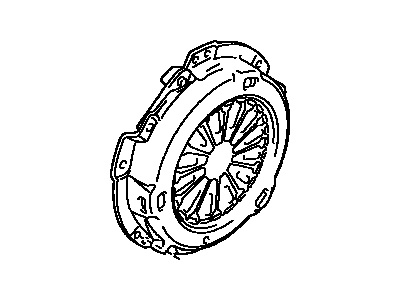

Part Number: 31210-12152-84$65.63 MSRP: $92.28You Save: $26.65 (29%)Ships in 1-3 Business Days

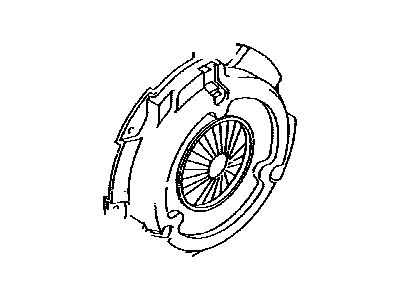

Toyota Corolla Pressure Plate

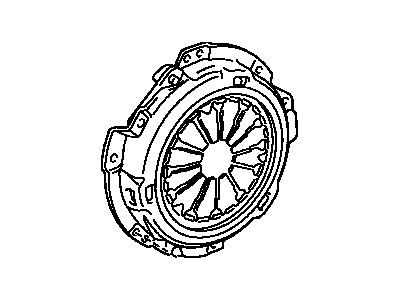

Part Number: 31210-02300$145.34 MSRP: $205.74You Save: $60.40 (30%)Ships in 1-3 Business Days

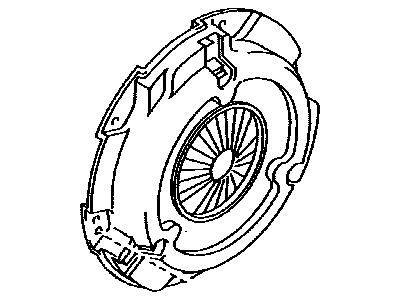

Toyota Corolla Pressure Plate

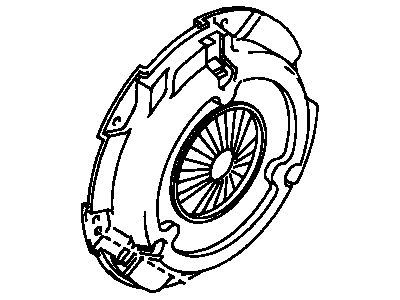

Part Number: 31210-02190$132.18 MSRP: $187.11You Save: $54.93 (30%)Ships in 1-3 Business Days

Toyota Corolla Pressure Plate

Part Number: 31210-33042$198.85 MSRP: $283.92You Save: $85.07 (30%)Ships in 1-3 Business DaysToyota Corolla Pressure Plate

Part Number: 31210-12210-84$57.71 MSRP: $80.48You Save: $22.77 (29%)Ships in 1-3 Business DaysToyota Corolla Pressure Plate

Part Number: 31210-12221-84$65.84 MSRP: $92.59You Save: $26.75 (29%)Ships in 1-3 Business DaysToyota Corolla Pressure Plate

Part Number: 31210-12201-84$62.08 MSRP: $87.33You Save: $25.25 (29%)Ships in 1-3 Business DaysToyota Corolla Pressure Plate

Part Number: 31210-12131-84$69.19 MSRP: $97.31You Save: $28.12 (29%)Ships in 1-3 Business DaysToyota Corolla Pressure Plate

Part Number: 31210-32121$188.05 MSRP: $268.50You Save: $80.45 (30%)Ships in 1-3 Business Days

Toyota Corolla Pressure Plate

Choose genuine Pressure Plate that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Pressure Plate for your Toyota Corolla? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Corolla parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Corolla Pressure Plate Parts and Q&A

- Q: How to overhaul the pressure plate on Toyota Corolla?A:Starting the pressure plate overhaul requires steps including manual transaxle assembly removal and subsequent clutch release fork sub-assembly extraction followed by the clutch release fork separation with its clutch release bearing from the transaxle assembly. Start by taking out the clutch release bearing assembly from the clutch release fork followed by removing the release fork support from the transaxle assembly then continuing with removal of the release bearing hub clip before taking the clutch release fork boot. Align the matchmarks from the clutch cover assembly on the flywheel sub-assembly before loosening each set bolt one turn to free up spring tension. Remove the clutch cover assembly after removing its six bolts and keep the Clutch Disc assembly from falling during removal. Remove the clutch disc assembly while maintaining the lining part of the clutch disc assembly together with the pressure plate and surface of the flywheel sub-assembly free from oil and all foreign substances. Vernier calipers must measure rivet head depth in the clutch disc assembly to ensure it stays under 0.3 mm (0.012 inch); if needed, replace the assembly. The correct direction insertion of the clutch disc assembly into the transaxle assembly demands measurement with a dial indicator to confirm runout below 0.8 mm (0.031 inch). If the runout reaches beyond 0.8 mm it requires replacement. Vernier calipers should be used to examine the clutch cover assembly, which requires diaphragm spring depth to remain below 0.5 mm (0.020 inch) and width to stay within 6.0 mm (0.236 inch); replace failed components. A dial indicator should be used to inspect flywheel sub-assembly runout which must be below 0.1 mm (0.004 inch) otherwise replacement is required. The clutch release bearing assembly should be checked by hand turning with axial loading until replacement becomes necessary. The installation requires using Special Service Tool: 09301-00210 to enter the clutch disc assembly before guiding it into the flywheel sub-assembly with the correct orientation. Follow the matchmark alignment while tightening the specified bolt order to 19.1 Nm (195 kgf-cm, 14 ft. lbs.) and check that the disc stays centered during this process. Use the dial indicator with roller instrument to check diaphragm spring tip alignment on the clutch cover assembly during inspection and adjustment until it reaches within 0.5 mm (0.020 inch); Special Service Tool: 09333-00013 helps with any required adjustments. The installation order begins with the clamp support of the support assembly to the transaxle assembly at 36.8 Nm (375 kgf-cm, 27 ft. lbs.) torque followed by the bearing hub release clip and the clutch release fork sub-assembly. Release hub grease (Part No. 08887-01806) is essential for each contact point before assembly. Pre-installation requires the input shaft spline to receive clutch spline grease (Part No. 08887-01706) then verify the release bearing shows smooth movement before completing the installation. The manual transaxle assembly should be put together after installing the clutch release fork boot.

- Q: How to service and repair the pressure plate on Toyota Corolla?A:Service and repair of the pressure plate begins by extracting the transaxle from the engine followed by Clutch Disc removal involving positioning the clutch cover matchmark with the flywheel mark then untightening each set bolt with small turns until spring tension releases. After this the technician carefully extracts the clutch cover combined with the clutch disc without letting the disc drop. The service begins with the removal of the release bearing and fork together before separating them and concluding with removal of the release fork support and boot. The clutch disc inspection requires using calipers to measure rivet head depth which must exceed 0.3 mm (0.012 inch) depth; otherwise replace the clutch disc. Inspect the clutch disc runout using a dial indicator and maintain replacement if this is above 0.8 mm (0.031 inch), simultaneously check the flywheel runout which should not pass 0.1 mm (0.004 inch) before replacing the flywheel. The diaphragm spring requires replacement when its depth measurement exceeds 0.5 mm (0.020 inch) and its width measurement exceeds 6.0 mm (0.236 inch). The release bearing requires replacement if you find signs of wear during a manual turning test with applied axial force. Special Service Tool: 09301-00210 should be inserted into the clutch disc before placing it on the flywheel with correct direction installation. Finally secure the 6 bolts in the correct sequence to a torque of 19 Nm (195 kgf-cm, 14 ft. lbs.) while ensuring even tightening and checking for disc centering. The technician must verify diaphragm spring tip alignment using a dial indicator until it stays within 0.5 mm (0.020 inch). When out of range they should employ Special Service Tool: 09333-00013 to make adjustments. The transaxle must receive the boot and release fork support with product torque set to 37 Nm (375 kgf-cm, 27 ft. lbs.). Subsequently apply molybdenum disulphide lithium base grease (NLGI NO. 2) at the mentioned contact points. The technician applies recommended grease part number 08887-01706 (100g) to the release fork and release bearing contact points as well as the release fork and push rod contact point and the release fork and pivot point and the clutch spline. Reinstall the transaxle to the engine after you insert both the release bearing and fork onto the transaxle.