×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Scion Crankshaft Position Sensor

Engine Crankshaft Position Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Crankshaft Position Sensors found

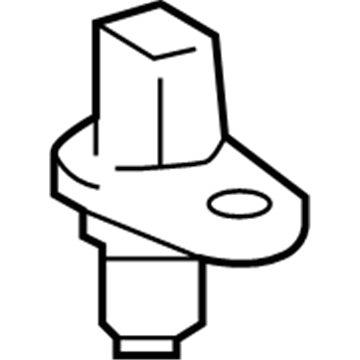

Scion Sensor, Camshaft Position

Part Number: 90080-19014$69.78 MSRP: $83.30You Save: $13.52 (17%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Crank Position; Cam Position; Engine Camshaft; Crankshaft; RPM Sensor

- Replaces: 90919-05026

Scion Camshaft Position Sensor, Driver Side

Part Number: 90919-T5005$102.96 MSRP: $144.53You Save: $41.57 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor, Crank Position; Engine Camshaft Position Sensor, Left; Crankshaft Position Sensor; Camshaft Sensor; Cam Sensor; Sensor, Cam Position; Engine Camshaft Position Sensor

- Manufacturer Note: (L)

- Position: Driver Side

- Replaces: 9004A-19003, 90919-05060, 90919-T5002

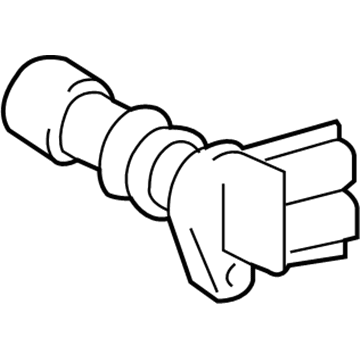

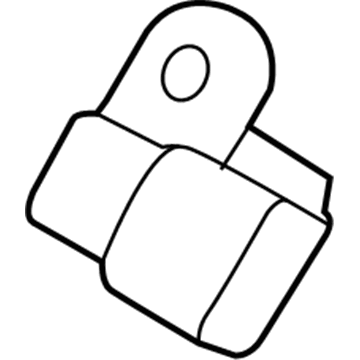

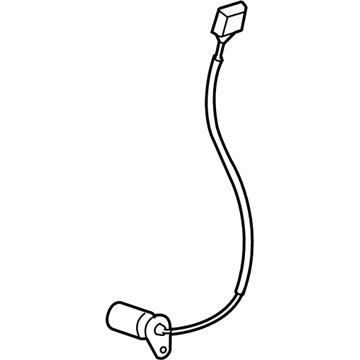

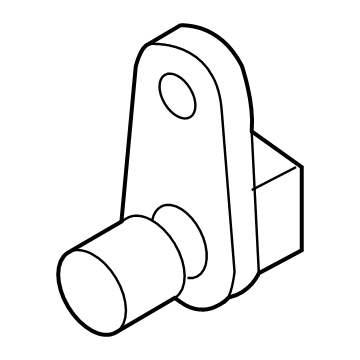

Scion Crankshaft Position Sensor

Part Number: 90919-A5004$99.41 MSRP: $139.54You Save: $40.13 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor, Crank Position; Engine Crankshaft Position Sensor; Sensor, Crankshaft Pulse; Crankshaft Sensor; Camshaft Position Sensor

- Replaces: 90919-05070

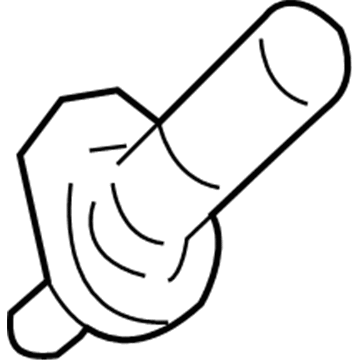

Scion Crankshaft Position Sensor

Part Number: 90080-19024$138.40 MSRP: $195.92You Save: $57.52 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Crank Position; Engine Crankshaft Position Sensor; Crankshaft Sensor

- Replaces: 90919-05047

Scion Crankshaft Position Sensor

Part Number: SU003-00412$96.33 MSRP: $125.75You Save: $29.42 (24%)Ships in 1 Business DayProduct Specifications- Other Name: Sensor Assembly-Crankshaft; Engine Crankshaft Position Sensor; Crankshaft Sensor; Sensor, Crank Position

Scion Crankshaft Position Sensor

Part Number: 90919-05073$113.39 MSRP: $159.17You Save: $45.78 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor, Crank Position; Engine Crankshaft Position Sensor; Engine Camshaft Position Sensor; Camshaft Sensor; Cam Sensor; Camshaft Position Sensor; Crankshaft Sensor; Sensor, Camshaft Position; Sensor, Cam Position

- Manufacturer Note: NO.2

- Replaces: 9004A-19004, 90919-T5001

Scion Crankshaft Position Sensor

Part Number: 90919-05067$116.24 MSRP: $163.16You Save: $46.92 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor, Crank Position; Engine Crankshaft Position Sensor; Crankshaft Sensor

- Manufacturer Note: *194

Scion Crankshaft Position Sensor

Part Number: 90919-05087$77.49 MSRP: $108.76You Save: $31.27 (29%)Ships in 1 Business DayProduct Specifications- Other Name: Sensor, Crank Position; Engine Crankshaft Position Sensor; RPM Sensor, Engine Management; Crankshaft Sensor

- Replaces: 90919-05045, 90919-05081

Scion Crankshaft Position Sensor

Part Number: 90118-WB438$57.81 MSRP: $80.48You Save: $22.67 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Crankshaft Position; Engine Crankshaft Position Sensor; Crankshaft Sensor; Sensor, Crank Position

Scion Crankshaft Position Sensor

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Scion produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Scion Crankshaft Position Sensor? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

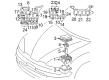

The Scion Crankshaft Position Sensor provides real-time crank angle sensor information to ensure ignition and fuel timing are as sharp as possible. Scion exploded onto the roads in 2003 and targeted a driver who wanted to enjoy daring paint, booming stereos, and a price that did not involve playing the haggle game. Scion eliminated fat option packages, had a single comprehensive trim per model, and allowed customers to pile components to the point that every ride had the tunes and trainers of their liking. With small Release Series drops, which transformed the parking lots into one-night pop-up performances, Scion continued to keep the buzz going and maintain collectors scavenging the internet after VIN stickers. Scion was the guinea pig of Toyota, with the introduction of edgy dashboards, cartoon advertisements, and virtual city long before it was being disseminated into the standard showrooms. By 2016, more than 1,000,000 compacts had abandoned show floors, but the mix-and-match mindset of the badge is reflected in the current mania of customization. The Crankshaft Position Sensor is located next to the flywheel and has a rapid pulse train firing, which allows the ECU to determine the crank angle within fractions of a degree as revs soar up. The Crankshaft Position Sensor even coordinates the firing and fuel with agonizing heat, incessant shaking, and oily fog that would have burned inferior electronics. The Crankshaft Position Sensor signals the computer of misfires immediately as they spark, thus throttle response remains sharp rather than stuttering. The failure of the Crankshaft Position Sensor manifests as long cranking, rough idling, and an ugly drop in mileage, evidence that this thumb-sized device safeguards performance each and every mile.

Scion Crankshaft Position Sensor Parts and Q&A

- Q: How to service the Crankshaft Position Sensor on Scion tC?A:The first step to service the Crankshaft Position Sensor involves disconnecting the negative battery terminal cable while allowing at least 90 seconds to pass before starting work because this time delay stops the Air Bag and seat belt pretensioner activation. Before starting remove the front fender apron seal RH as well as the fan and generator V belt then the generator assembly. To access the crankshaft position sensor you must first disconnect its sensor connector before removing the connector clamp while sliding out the wire harness from its wire harness clamp bracket and then removing the wire harness clamp together with the bolt and sensor. For sensor installation place the O-ring under light engine oil application before putting the bolt into its place while tightening to 9.0 N.m (90 kgf.cm, 80 in.lbf). The next step is to install the wire harness clamp followed by the connector clamp before connecting the sensor connector while securing the wire harness through the back of the timing chain cover rib. Put together the generator assembly while installing the fan followed by the V belt belonging to the generator and finish the installation with a cable connection to the battery terminal's negative side. Engine oil leaks must be checked while installing the front fender apron seal RH and the system requires initialization after reconnecting battery cables from the negative terminal.

- Q: How to install the crankshaft position sensor and generator assembly on Scion xB?A:The crankshaft position sensor needs installation with a torque of 9.0 Nm (90 kgf-cm, 80 in-lbf) when using the bolt to secure it. Before this step, coat the O-ring with engine oil and make sure to avoid twisting the O-ring during installation. Start by installing the wire harness followed by the crankshaft position sensor connector clamp and conclude with sensor connector connection. Install the generator assembly by using two bolts on which Bolt A requires a torque of 21 Nm (215 kgf-cm, 16 ft-lbf) and Bolt B needs 52 Nm (530 kgf-cm, 38 ft-lbf). Fasten the generator wire to terminal B and tighten with a nut which reaches 9.8 Nm (100 kgf-cm, 87 in-lbf) torque. Then secure the clamp before connecting the generator connector. The fan and generator V belt gets installed after both wire harness clamps receive installation. Continue installation of the engine under cover rear RH while connecting the cable to the negative battery terminal at a torque of 5.4 Nm (55 kgf-cm, 48 in-lbf). Check for oil leakage as the last step.