×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

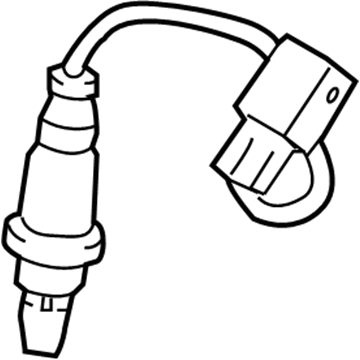

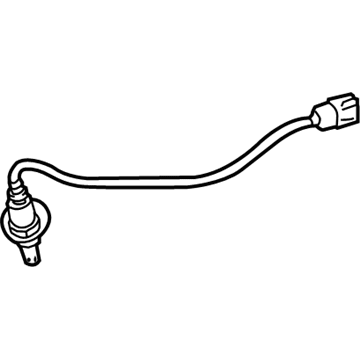

OEM Toyota Sienna Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

37 Oxygen Sensors found

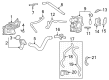

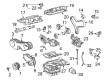

Toyota Sienna Oxygen Sensor, Driver Side

Part Number: 89467-48050$223.67 MSRP: $319.34You Save: $95.67 (30%)Ships in 1-2 Business Days

Toyota Sienna Oxygen Sensor, Passenger Side

Part Number: 89465-08070$109.01 MSRP: $153.01You Save: $44.00 (29%)Ships in 1-3 Business Days

Toyota Sienna Oxygen Sensor, Rear Passenger Side

Part Number: 89465-08100$127.48 MSRP: $180.45You Save: $52.97 (30%)Ships in 1-3 Business Days

Toyota Sienna Oxygen Sensor, Rear

Part Number: 89465-08010$121.37 MSRP: $171.81You Save: $50.44 (30%)Ships in 1-3 Business Days

Toyota Sienna Oxygen Sensor, Driver Side

Part Number: 89465-48170$151.92 MSRP: $215.06You Save: $63.14 (30%)Ships in 1 Business Day

Toyota Sienna Oxygen Sensor, Front

Part Number: 89465-06100$122.89 MSRP: $173.97You Save: $51.08 (30%)Ships in 1-3 Business Days

Toyota Sienna Oxygen Sensor, Driver Side

Part Number: 89465-08090$109.01 MSRP: $153.01You Save: $44.00 (29%)Ships in 1-3 Business Days

Toyota Sienna Sensor, Air Fuel Ratio, Driver Side

Part Number: 89467-0E040$240.09 MSRP: $342.80You Save: $102.71 (30%)Ships in 1-3 Business DaysToyota Sienna Lower Oxygen Sensor, Rear Driver Side

Part Number: 89465-08150$131.94 MSRP: $186.78You Save: $54.84 (30%)Ships in 1-3 Business DaysToyota Sienna Oxygen Sensor, Driver Side

Part Number: 89467-08070$199.90 MSRP: $285.41You Save: $85.51 (30%)Ships in 1-2 Business DaysToyota Sienna Oxygen Sensor, Passenger Side

Part Number: 89465-08080$109.01 MSRP: $153.01You Save: $44.00 (29%)Ships in 1-3 Business DaysToyota Sienna Oxygen Sensor, Passenger Side

Part Number: 89465-08051$113.04 MSRP: $158.66You Save: $45.62 (29%)Ships in 1-3 Business DaysToyota Sienna Sensor, Oxygen, Rear Driver Side

Part Number: 89465-08120$158.38 MSRP: $224.20You Save: $65.82 (30%)Ships in 1-2 Business DaysToyota Sienna Oxygen Sensor, Front

Part Number: 89467-45030$194.89 MSRP: $278.27You Save: $83.38 (30%)Ships in 1-3 Business DaysToyota Sienna Oxygen Sensor, Rear

Part Number: 89465-08110$117.42 MSRP: $164.82You Save: $47.40 (29%)Ships in 1-3 Business DaysToyota Sienna Oxygen Sensor, Rear

Part Number: 89465-45010$149.08 MSRP: $211.05You Save: $61.97 (30%)Ships in 1-3 Business DaysToyota Sienna Oxygen Sensor, Rear Passenger Side

Part Number: 89465-08130$117.42 MSRP: $164.82You Save: $47.40 (29%)Ships in 1-3 Business DaysToyota Sienna Oxygen Sensor, Rear Passenger Side

Part Number: 89465-08140$117.42 MSRP: $164.82You Save: $47.40 (29%)Ships in 1-3 Business DaysToyota Sienna Oxygen Sensor, Front

Part Number: 89467-0E280$182.54 MSRP: $260.63You Save: $78.09 (30%)Ships in 1-3 Business DaysToyota Sienna Oxygen Sensor, Front Passenger Side

Part Number: 89467-06180$186.74 MSRP: $266.61You Save: $79.87 (30%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 37 Results

Toyota Sienna Oxygen Sensor

Choose genuine Oxygen Sensor that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Oxygen Sensor for your Toyota Sienna? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Sienna parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Sienna Oxygen Sensor Parts and Q&A

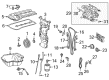

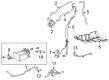

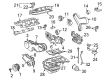

- Q: How to install the Oxygen Sensor for Bank 2 Sensor 1 on Toyota Sienna?A:Special Service Tool 09224-00010 helps in mounting the sensor onto the exhaust manifold LH using a torque of 40 Nm (408 kgf-cm, 30 ft-lbf) with the tool or 44 Nm (449 kgf-cm, 32 ft-lbf) without it under the condition that the torque wrench possesses a 30 cm (11.81 in.) fulcrum length and maintains a straight alignment with the tool. Connect the sensor connector. The Sensor 1 Bank 1 requires another installation phase with the same tool to attach it to exhaust manifold RH while applying torque specifications before connector connection. After setting down the exhaust manifold RH using new gasket and 6 nuts to 21 Nm (214 kgf-cm, 15 ft-lbf) torque you must apply a nut and bolt connection on the exhaust manifold stay to 35 Nm (357 kgf-cm, 26 ft-lbf) torque before finishing with the air fuel ratio sensor for Bank 1 Sensor 2 installation. Measurement of compression springs using vernier calipers should be 38.86 mm (1.5299 in.) and triggering a replacement if the reading is off. Use hand placement to mount a fresh gasket on the front Exhaust Pipe before hitting it smooth with a plastic mallet through a wooden block while avoiding damage by keeping proper installation orientation and preserving the gasket from reuse. At 43 Nm (440 kgf-cm, 32 ft-lbf) torques apply 2 new gaskets to the front exhaust pipe assembly through the installation of 2 nuts and 2 bolts. Mount the center exhaust pipe assembly by inserting 2 compression springs along with 2 bolts that need to be torqued to 43 Nm (438 kgf-cm, 32 ft-lbf). This process should be followed by inserting the clip before connecting the heated oxygen sensor for Bank 1 Sensor 2. An inspection for exhaust gas leaks should be conducted after connecting the cable to the negative battery terminal.

- Q: How to service and repair the heated oxygen sensor on Toyota Sienna?A:The process of servicing the heated oxygen sensor includes disconnecting the negative battery terminal cable as the first step for 2GR-FE emission control system in 4WD vehicles. The heated oxygen sensor for Bank 1 Sensor 2 requires disconnecting the sensor connector which is beneath the center console and subsequent removal with tool 09224-00010. The removal process starts by disconnecting the heated oxygen sensor connector for Bank 2 Sensor 2 after which the technician should continue by uninstalling the 2 bolts and 4 nuts holding the assembly together. Proceed by removing Bank 2 Sensor 2 from the front Exhaust Pipe assembly while using Special Service Tool.