×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Corolla Ball Joint

Control Arm Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Ball Joints found

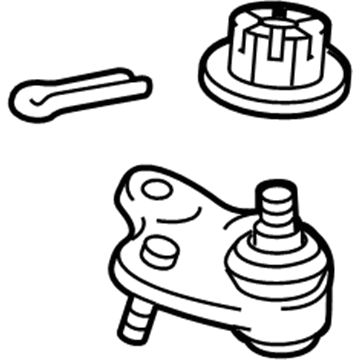

Toyota Corolla Ball Joint, Lower

Part Number: 43330-19115$62.67 MSRP: $87.98You Save: $25.31 (29%)Ships in 1-3 Business Days

Toyota Corolla Lower Ball Joint

Part Number: 43330-09670$57.23 MSRP: $79.65You Save: $22.42 (29%)Ships in 1-2 Business Days

Toyota Corolla Ball Joint, Lower

Part Number: 43330-09230$65.52 MSRP: $91.97You Save: $26.45 (29%)Ships in 1-3 Business DaysToyota Corolla Ball Joint, Lower

Part Number: 43330-09B00$57.23 MSRP: $79.65You Save: $22.42 (29%)Ships in 1-3 Business DaysToyota Corolla Ball Joint, Front Driver Side

Part Number: 43340-19016$69.78 MSRP: $97.95You Save: $28.17 (29%)Toyota Corolla Ball Joint, Front

Part Number: 43330-29205$73.70 MSRP: $103.44You Save: $29.74 (29%)Ships in 1-3 Business Days

Toyota Corolla Ball Joint, Front Passenger Side

Part Number: 43330-19066$71.09 MSRP: $99.79You Save: $28.70 (29%)

Toyota Corolla Ball Joint

Choose genuine Ball Joint that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Ball Joint for your Toyota Corolla? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Corolla parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

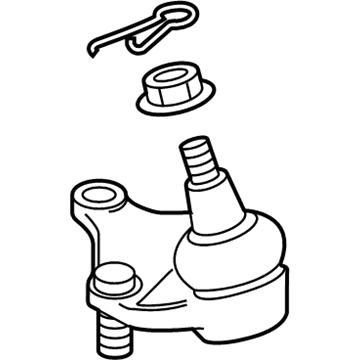

Toyota Corolla Ball Joint Parts and Q&A

- Q: How to install the front lower ball joint on Toyota Corolla?A:The installation process for the front lower ball joint starts with placing the front axle assembly in a vise which requires aluminum plates but avoids overtightening of any components. Fill the front axle assembly with a new nut while applying a 103 Nm (1050 kgf-cm, 76 ft-lbf) torque on 2ZR-FE engines and 123 Nm (1254 kgf-cm, 91 ft-lbf) on 2AZ-FE engines before adding a new cotter pin that requires an extra torque adjustment to 60 degrees when the cotter pin holes are not aligned. The front lower suspension arm mounts to the lower ball joint through a bolt along with two nuts before tightening them to 89 Nm (908 kgf-cm, 66 ft-lbf). Fasten the front Speed Sensor to the Steering Knuckle with a bolt that requires 8.5 Nm (87 kgf-cm, 75 in-lbf) torque while ensuring the speed sensor remains untwisted. The front flexible hose and speed sensor installation should be done by tightening a bolt to 29 Nm (296 kgf-cm, 21 ft-lbf). The installation of the front wheel requires a torque of 103 Nm (1050 kgf-cm, 76 ft-lbf) while performing front wheel alignment inspection and adjustment. Inspection of the speed sensor signal should be conducted last to guarantee proper functionality.

- Q: How to remove the front lower ball joint on Toyota Corolla?A:Start the process of removing the front lower ball joint by taking off the front wheel followed by removing the front Axle Shaft LH nut using Special Service Tool: 09930-00010. First disconnect the Speed Sensor front LH (with ABS) followed by separating the tie rod end sub-assembly LH through the use of Special Service Tool: 09628-62011. Separate the front suspension arm sub-assembly lower No. 1 LH and the front axle assembly LH after the initial steps. The last step involves unfastening the lower ball joint assembly front LH by removing the cotter pin and castle nut followed by the usage of Special Service Tool: 09628-62011 to disconnect it from the Steering Knuckle LH.