×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

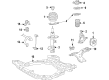

OEM Toyota Corolla Front Cross-Member

Front Engine Cross Member- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

24 Front Cross-Members found

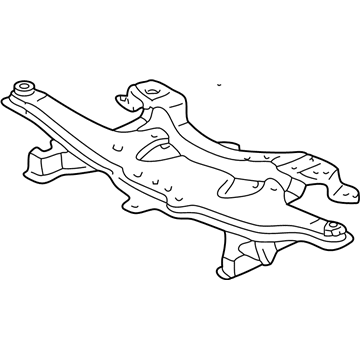

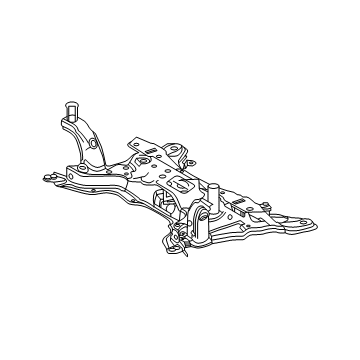

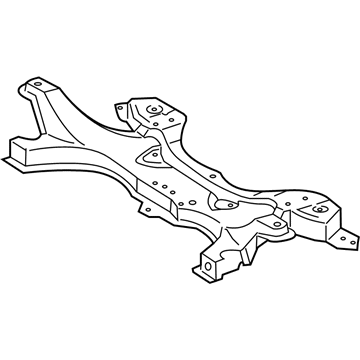

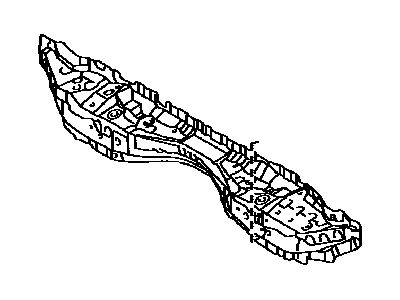

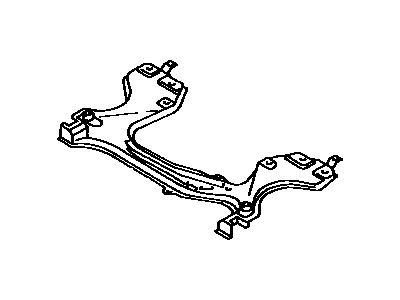

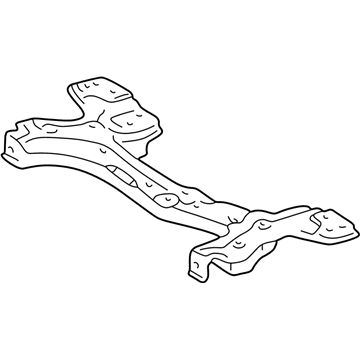

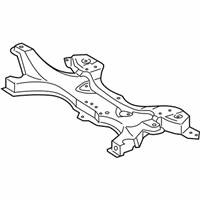

Toyota Corolla Engine Cradle, Front

Part Number: 51201-02152$868.94 MSRP: $1273.45You Save: $404.51 (32%)Ships in 1-3 Business Days

Toyota Corolla Engine Cradle, Front

Part Number: 51201-47072$1145.09 MSRP: $1678.14You Save: $533.05 (32%)Ships in 1-3 Business DaysToyota Corolla Front Crossmember, Driver Side

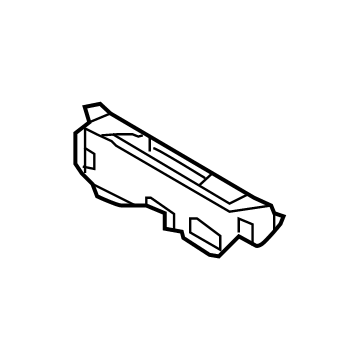

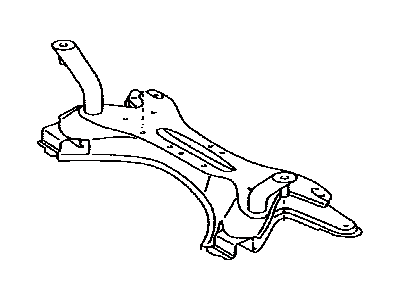

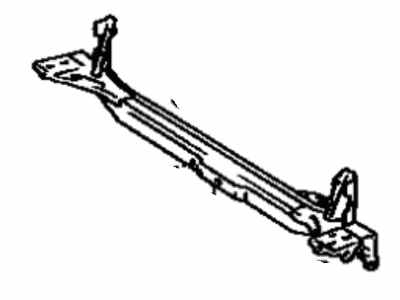

Part Number: 57452-02140$154.67 MSRP: $218.94You Save: $64.27 (30%)Ships in 1-3 Business DaysToyota Corolla Front Crossmember

Part Number: 57451-12131$129.98 MSRP: $184.00You Save: $54.02 (30%)Ships in 1-3 Business DaysToyota Corolla Front Crossmember, Passenger Side

Part Number: 57451-02100$154.67 MSRP: $218.94You Save: $64.27 (30%)Ships in 1-3 Business DaysToyota Corolla Front Crossmember

Part Number: 57451-12130$56.49 MSRP: $78.63You Save: $22.14 (29%)Ships in 1-3 Business DaysToyota Corolla Rear Rail Assembly, Front Passenger Side

Part Number: 57611-47904$707.32 MSRP: $1036.59You Save: $329.27 (32%)Ships in 1-3 Business DaysToyota Corolla Engine Cradle

Part Number: 51201-20352$1040.78 MSRP: $1525.28You Save: $484.50 (32%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 24 Results

Toyota Corolla Front Cross-Member

Choose genuine Front Cross-Member that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Front Cross-Member for your Toyota Corolla? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Corolla parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Corolla Front Cross-Member Parts and Q&A

- Q: How to remove the front cross-member on Toyota Corolla?A:The first step to removing the front cross-member involves placing the front wheels in a straight-ahead position then securing the Steering Wheel. Begin by taking out the column hole cover silencer sheet before distinguishing the No. 2 steering intermediate shaft assembly from the No. 1 steering column hole cover sub-assembly. The next step requires users to eliminate engine under covers starting from both left to right before removing front wheels. The first step includes breaking apart the tie rod end sub-assemblies at both the left side and right side locations followed by dividing the front stabilizer link assemblies at both sides before continuing. Next proceed with separating both front lower suspension arms from both the left and the right sides. You must detach the 3 bolts and 3 nuts holding down the front suspension crossmember sub-assembly before using a transmission jack to support it and then unfastening the 4 bolts. Support the transmission during removal of the front hook assembly by eliminating its 2 securing bolts. Warner motorists should detach the center engine mounting member sub-assembly by removing all 4 bolts. Users of TMC vehicles need to detach the front suspension member dynamic damper bolt yet other vehicles only require disassembly of the front suspension member dynamic damper. You need to take out the front stabilizer bar and steering link assembly after removing the front lower suspension arms that you must remove from both left and right sides using the same method twice.

- Q: How to install the Front Cross-Member on Toyota Corolla?A:The first installation step for the front suspension member requires mounting the front stabilizer bar and steering link assembly and then moving onto the front lower suspension arms. Mount both left and right front lower suspension arms on their respective sides only for temporary purposes. When installing the dynamic damper on front suspension members of TMC Made vehicles apply 52 Nm torque to the bolt; other models require only damper installation. The sub-assembly of the center engine mounting member requires temporary installation with four bolts. Use Special Service Tool: 09670-00010 to insert into both sides of front suspension crossmember sub-assembly guide holes before TMC Made vehicles can tighten bolts A to 113 Nm, bolts B to 157 Nm, bolt C to 52 Nm, and nuts D to 52 Nm. Other vehicle models require users to install Bias Plates then tighten Bolt D to 87 Nm and Nut E to 52 Nm. The center engine mounting member assembly requires four bolts to be fully tightened according to the specifications of 39 Nm for Bolt A (TMC Made) or 60 Nm (except TMC Made) and 52 Nm for Bolt B (TMC Made) or 81 Nm (except TMC Made). Doctors should tighten two front hook assembly bolts to 39 Nm torque. Tighten the front lower suspension arms, stabilizer link assemblies and tie rod end sub-assemblies of both sides. The first step involves setting the engine under both covers while attaching the No. 1 steering column hole cover sub-assembly together with the No. 2 steering intermediate shaft assembly. First position the wheels exactly straight ahead before adding the column hole cover silencer sheet and tightening the front wheels to 103 Nm (1050 kgf-cm, 76 ft-lbf). Both front lower suspension arms need full stabilization while the technician tightens them to specifications. Examining and correcting front wheel alignment must be performed as the final step.