×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Camry Water Pump

H2O Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

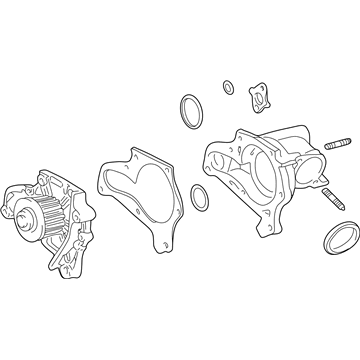

17 Water Pumps found

Toyota Camry Water Pump

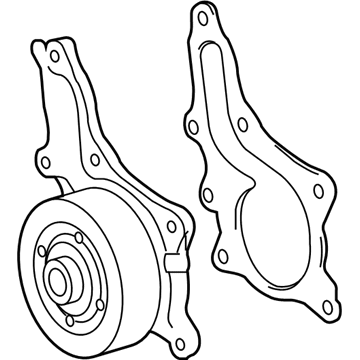

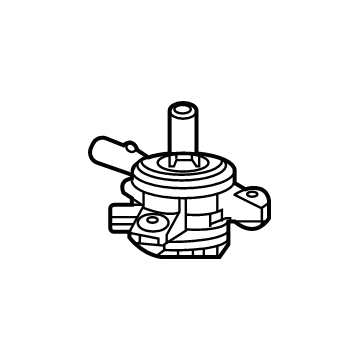

Part Number: 16100-69076-77$57.24 MSRP: $79.83You Save: $22.59 (29%)Ships in 1-3 Business Days

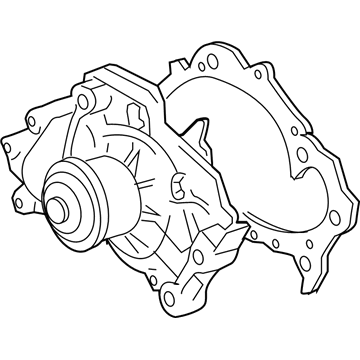

Toyota Camry Water Pump

Part Number: 16100-29085$75.09 MSRP: $105.41You Save: $30.32 (29%)Ships in 1-3 Business Days

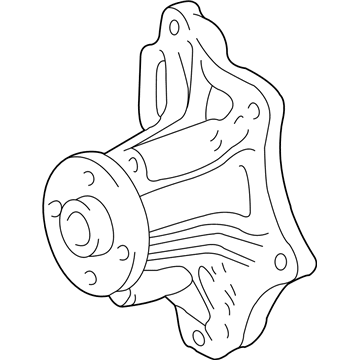

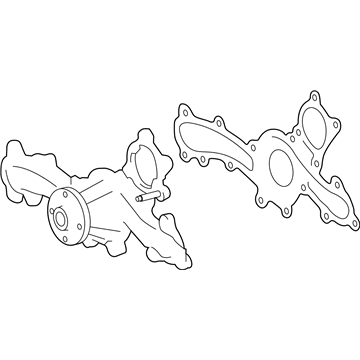

Toyota Camry Water Pump

Part Number: 16100-28041$109.60 MSRP: $153.85You Save: $44.25 (29%)Ships in 1-2 Business Days

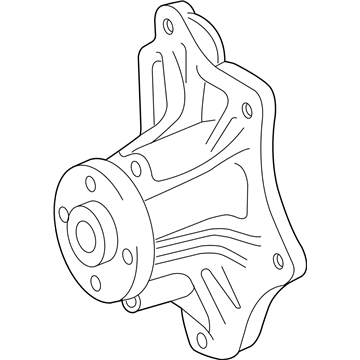

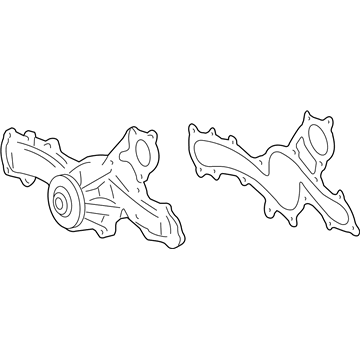

Toyota Camry Water Pump

Part Number: 16100-0H010$94.67 MSRP: $132.88You Save: $38.21 (29%)Ships in 1-3 Business Days

Toyota Camry Water Pump

Part Number: 16100-09515$115.17 MSRP: $161.66You Save: $46.49 (29%)Ships in 1-3 Business Days

Toyota Camry Water Pump

Part Number: G9020-33010$351.61 MSRP: $515.29You Save: $163.68 (32%)Ships in 1-3 Business Days

Toyota Camry Pump Assembly, Engine Water

Part Number: 16100-09690$131.59 MSRP: $186.27You Save: $54.68 (30%)Ships in 1-3 Business Days

Toyota Camry Water Pump Assembly

Part Number: 16100-69455-83$94.56 MSRP: $132.73You Save: $38.17 (29%)Ships in 1-3 Business DaysToyota Camry Water Pump

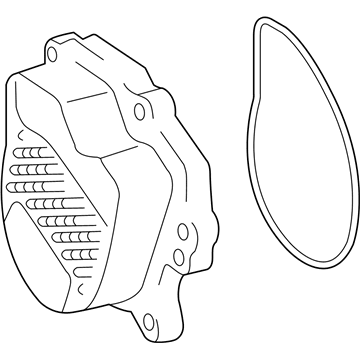

Part Number: G9040-48060$463.56 MSRP: $679.35You Save: $215.79 (32%)Ships in 1-2 Business DaysToyota Camry Auxiliary Pump

Part Number: 87200-33010$538.77 MSRP: $789.58You Save: $250.81 (32%)Ships in 1-3 Business DaysToyota Camry Water Pump

Part Number: 16100-69305$112.78 MSRP: $158.29You Save: $45.51 (29%)Ships in 1-3 Business DaysToyota Camry Water Pump

Part Number: G9040-33030$330.65 MSRP: $472.10You Save: $141.45 (30%)Ships in 1-3 Business DaysToyota Camry Water Pump

Part Number: 161A0-39025$327.57 MSRP: $467.71You Save: $140.14 (30%)Ships in 1-3 Business DaysToyota Camry Auxiliary Pump

Part Number: G9040-33050$541.04 MSRP: $792.90You Save: $251.86 (32%)Ships in 1-3 Business Days

Toyota Camry Water Pump

Choose genuine Water Pump that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Water Pump for your Toyota Camry? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Camry parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

Toyota Camry Water Pump Parts and Q&A

- Q: How to install the heater water pump and associated components on Toyota Camry?A:You should install the heater water pump by first tightening its 2 nuts to reach 9.8 Nm (100 kgf-cm, 87 in-lbf) then connecting the connector. Begin installation by fitting the heater water inlet hose which requires water hose attachment using a clip followed by installation of heater water outlet hose in exactly the same fashion. The cowl top panel outer sub-assembly must be installed with the windshield Wiper Motor and link assembly and cowl top ventilator louver sub-assembly. Start by installing the front fender to cowl side seal right and left before moving on to install the front wiper arm and blade assembly right and left. The appliance of the brake master cylinder reservoir sub-assembly completes the sequence.

- Q: How to remove the Auxiliary Water Pump on Toyota Camry?A:The workflow for removing the Auxiliary Water Pump requires first breaking free the Brake Master Cylinder Reservoir Sub-Assembly. You must disconnect the Front Wiper Blade followed by the Front Wiper Arm from both the left and right sides. The next step requires removal of the Front Fender to Cowl Side Seals from both left and right sides of the vehicle. Next follow procedure by taking off the Cowl Top Ventilator Louver Sub-Assembly and then proceed to remove the Windshield Wiper Motor and Link Assembly. Remove the Cowl Top Panel Outer Sub-Assembly from the vehicle after completing that operation. The Heater Water Outlet Hose can be disconnected by using pliers to grip the clip claws before sliding them out of position. The procedure to detach the Heater Water Inlet Hose matches the method required for its outlet counterpart. Finish the removal process by disconnecting the electric connector of the Heater Water Pump before unfastening its two securing nuts.