×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Scion xB Crankshaft Seal

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Crankshaft Seals found

Scion xB Rear Main Seal

Part Number: 90311-75022$40.26 MSRP: $56.03You Save: $15.77 (29%)Ships in 1 Business Day

Scion xB Front Crank Seal

Part Number: 90311-25032$9.31 MSRP: $12.96You Save: $3.65 (29%)Ships in 1 Business Day

Scion xB Oil Seal, Front

Part Number: 90080-31049$9.91 MSRP: $13.79You Save: $3.88 (29%)Ships in 1-3 Business Days

Scion xB Rear Main Seal

Part Number: 90311-89010$40.26 MSRP: $56.03You Save: $15.77 (29%)Ships in 1-3 Business Days

Scion xB Crankshaft Seal, Front

Part Number: 90311-38098$11.82 MSRP: $16.45You Save: $4.63 (29%)Ships in 1-3 Business Days

Scion xB Crankshaft Seal

Choose genuine Crankshaft Seal that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Crankshaft Seal for your Scion xB? Our website is your one-stop destination. We stock an extensive selection of genuine Scion xB parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

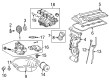

One of the important parts of the Scion xB is Crankshaft Seal that proves the reliability and performance of any car that belongs to Scion xB series. This Crankshaft Seal is mounted at the front, and its primary function is to stop the crankcase from leaking oil, which is crucial for proper lubrication and reduction of components' wear. Installed on the auto's crankcase, the Crankshaft Seal offers the prime of metals and rubber that adapts to diverse driving situations to deliver efficient as well as safe performance. Since this Crankshaft will work perfectly well for the xB models together with a number of other models that use the 1.5 L 1NZ-FE and 2.4 L 2AZ-FE engines, it is the perfect product for all Scion fans. With later generations of the xB models emerging, the Crankshaft Seal stayed as the basic component, but at the same time, the new types of materials and designs were integrated, so that the engine would remain tight and secure. Calls for adequate replacement since a bad Crankshaft Seal will cause oil leakage and serious damages to the engine. The Crankshaft Seal enjoys a positive reputation in terms of economic effectiveness of the car and its durability, which is highly appreciated in the market space as the foundation for successful performance and safe driving. All in all, the Crankshaft Seal is a perfect representation of what Scion stands for and that is quality and long lasting automobile.

Scion xB Crankshaft Seal Parts and Q&A

- Q: How to remove the rear Crankshaft Seal on Scion xB?A:The removal procedure for the 2AZ-FE rear crankshaft oil seal begins by taking out the appropriate transmission assemblies either automatic or manual. When working on manual transaxle it is necessary to remove clutch cover assembly and clutch disc assembly in addition to standard manual transaxle assembly removal. The automatic transaxle's drive plate and ring gear sub-assembly removal requires Special Service Tool: 09213-54015 91651-60855 to hold the crankshaft followed by 8 bolt removal and subsequent removal of rear drive plate spacer and drive plate and front drive plate spacer. The manual transaxle requires use of the same Special Service Tool to securely position the crankshaft prior to taking out 8 bolts that secure the flywheel sub-assembly and finally extracting the assembly itself. First tape a screwdriver tip before using it to pry out the rear crankshaft oil seal by cutting off its lip with a knife. Inspection of the crankshaft must happen after removal. You should also verify the crankshaft for damage while using 400-grit sandpaper to smoothen damaged areas.

- Q: How to install the front Crankshaft Seal on Scion xB?A:Insertion of the front crankshaft oil seal to the 2AZ-FE engine requires MP grease application to the new oil seal lip. By utilizing Special Service Tool: 09223-22010 and a hammer to tap the oil seal towards the rear oil seal retainer edge you should stop at the point where the surface matches the edge while maintaining the lip clean of foreign substances and avoiding angled tapping. The process starts with fixing the pulley in position through Special Service Tool: 09213-54015 91651-60855 while torquing the bolt to 180 Nm (1835 kgf-cm, 133 ft-lbf) using Special Service Tool: 09330-00021. Proceed to install the fan and generator V belt before looking for engine oil leaks and checking engine oil level. Finish the repair by attaching both the rear engine under cover right-hand and the front wheel right-hand then torque the wheel to 103 Nm (1050 kgf-cm, 76 ft-lbf).