×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Scion Variable Timing Sprocket

Timing Gear Sprocket- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

17 Variable Timing Sprockets found

Product Specifications

Product Specifications- Other Name: Gear Assembly, Camshaft; Variable Valve Timing Sprocket; Cam Gear; Intake Gear; Actuator; Gear Assembly, Camshaft Timing

- Replaces: 13050-0V030, 13050-0V070, 13050-36030

Scion Timing Gear

Part Number: 13523-0D010$43.84 MSRP: $61.03You Save: $17.19 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sprocket, Camshaft Timing; Engine Timing Camshaft Sprocket, Left, Right; Variable Valve Timing Sprocket; Cam Gear; Camshaft Gear; Exhaust Gear; Sprocket; Gear Or Sprocket, Camshaft Timing

- Replaces: 13523-0D020, 13523-22050, 13523-22020

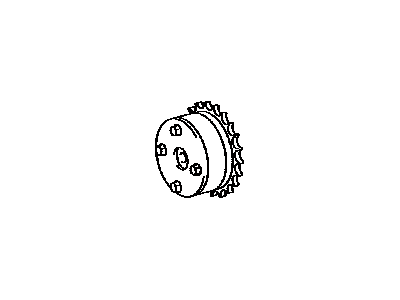

Scion Actuator

Part Number: 13070-47010$291.59 MSRP: $416.32You Save: $124.73 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gear Assembly, Camshaft; Variable Valve Timing Sprocket; Gear Assembly, Camshaft Timing Exhaust

Product Specifications

Product Specifications- Other Name: Gear Assembly, Camshaft; Engine VVT Sprocket; Timing Sprocket; Cam Gear; Exhaust Gear; Actuator; Sprocket; Gear Assembly, Camshaft Timing Exhaust

- Replaces: 13070-0V010, 13070-0V011, 13070-0V012, 13070-36011, 13070-36010

Scion Exhaust Gear

Part Number: 13070-0T011$302.07 MSRP: $431.30You Save: $129.23 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Gear Assembly, Camshaft; Variable Valve Timing Sprocket; Cam Gear; Actuator; Gear Assembly, Camshaft Timing Exhaust

- Manufacturer Note: (L)

- Replaced by: 13070-37010

- Replaces: 13070-0Y020, 13070-37010, 13070-0T010

Product Specifications

Product Specifications- Other Name: Gear Assembly, Camshaft; Engine VVT Sprocket; Timing Sprocket; Cam Gear; Intake Gear; Actuator; Gear Assembly, Camshaft Timing

- Replaces: 13050-36011, 13050-0V010, 13050-36010

Product Specifications

Product Specifications- Other Name: Gear Assembly, Camshaft; Engine VVT Sprocket; Camshaft Adjuster; Cam Gear; Actuator; Gear Assembly, Camshaft Timing

- Manufacturer Note: (L)

- Replaces: 13050-0T021, 13050-0T011, 13050-0T010

Scion Actuator

Part Number: 13050-47011$260.37 MSRP: $371.75You Save: $111.38 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gear Assembly, Camshaft; Variable Valve Timing Sprocket; Gear Assembly, Camshaft Timing

- Replaces: 13050-47010

Scion Camshaft Gear, Passenger Side

Part Number: 13050-28021$260.37 MSRP: $371.75You Save: $111.38 (30%)Ships in 1 Business DayProduct Specifications- Other Name: Gear Assembly, Camshaft; Engine Timing Camshaft Sprocket; VVT Sprocket; Cam Gear; Gear Assembly, Camshaft Timing

- Position: Passenger Side

- Replaces: 13050-0H010, 13050-28020, 13050-0H030

Scion Camshaft Gear

Part Number: 13050-21041$280.17 MSRP: $400.02You Save: $119.85 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Gear Assembly, Camshaft; Engine VVT Sprocket; Cam Gear; Actuator; Gear Assembly, Camshaft Timing

- Replaces: 13050-21040

- Product Specifications

- Other Name: Gear, Camshaft Timing; Variable Valve Timing Sprocket; Cam Gear; Gear Or Sprocket, Camshaft Timing

- Product Specifications

- Other Name: Gear Assembly, Camshaft; Variable Valve Timing Sprocket; Cam Gear; Exhaust Gear; Actuator; Gear Assembly, Camshaft Timing Exhaust

- Replaces: 13070-36030

Scion Actuator

Part Number: 13070-0T040$294.27 MSRP: $420.15You Save: $125.88 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gear Assembly, Camshaft; Variable Valve Timing Sprocket; Gear Assembly, Camshaft Timing Exhaust

- Manufacturer Note: (L)

- Replaces: 13070-37020

Scion Camshaft Gear

Part Number: 13050-0T040$281.57 MSRP: $402.02You Save: $120.45 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gear Assembly, Camshaft; Variable Valve Timing Sprocket; Cam Gear; Actuator; Gear Assembly, Camshaft Timing

- Manufacturer Note: (L)

- Replaces: 13050-37050

Scion Actuator, Driver Side

Part Number: SU003-05180$198.00 MSRP: $262.92You Save: $64.92 (25%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sprocket Assembly-Camshaft Timing, Exhaust Left-Hand; Variable Valve Timing Sprocket; Gear Assembly, Camshaft Timing Exhaust, Driver Side

- Position: Driver Side

- Replaces: SU003-00287

Scion Actuator

Part Number: 13520-WB001$225.47 MSRP: $321.92You Save: $96.45 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sprocket Assembly, Camshaft Timing; Variable Valve Timing Sprocket; Gear Assembly, Camshaft Timing

Product Specifications

Product Specifications- Other Name: Sprocket, Camshaft Timing; Engine Timing Camshaft Sprocket, Right; Variable Valve Timing Sprocket; Cam Gear; Sprocket; Gear Or Sprocket, Camshaft Timing

- Position: Passenger Side

Scion Variable Timing Sprocket

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Scion produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Scion Variable Timing Sprocket? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

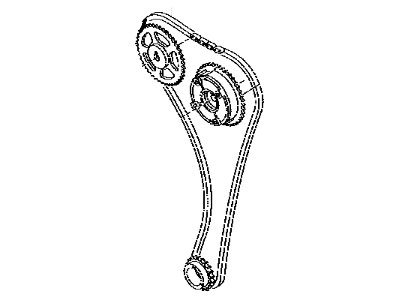

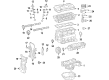

The Scion Variable Timing Sprocket also adjusts the timing of the cam timing in a way that the engine runs more readily at every rpm, providing young drivers with more pull and better mileage. In 2003, Scion was launched with the daring colors, plain prices and interactive advertising such as the Virtual Scion City that invited first time buyers to the showroom. The fact that Scion was able to consider every car a blank canvas made the owners customize their cars and the limited Release Series kept the buzz high. Scion was a rolling test lab which brought new technology to the market swiftly and sold over a million vehicles before the brand closed its doors in 2016, but its spirit continues to influence Toyota today. A Variable Timing Sprocket is a intelligent cam gear that changes the timing at which the valves open and close, with respect to the crankshaft, to increase power, fuel economy, and emissions performance throughout the rev range. In order to fit a Variable Timing Sprocket to a Scion engine, disconnect the battery, and remove any covers and adjust the crank until the timing marks align at top dead center. Turn the camshafts, loosen the chain or belt and unbolt the old Variable Timing Sprocket, keeping the marks in sight. Install the new sprocket using the index lines to align the new sprocket to the factory marks, put threadlocker on the bolts, and tighten them to specification, re-tension the drive, rotation the crank by hand two full rotations to check alignment, re-assemble the covers, reconnect the battery, clear stored faults, and start the engine to ensure smooth operation.