×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM 2008 Toyota Land Cruiser Exhaust Pipe

Exhaust Tail Pipe- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Exhaust Pipes found

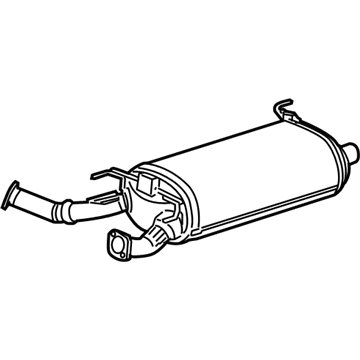

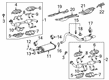

2008 Toyota Land Cruiser Pipe Assembly, Exhaust, Center

Part Number: 17420-38100$599.61 MSRP: $804.85You Save: $205.24 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Exhaust Pipe; Tail Pipe; Muffler

- Position: Center

- Part Name Code: 17420

- Item Weight: 17.20 Pounds

- Item Dimensions: 41.0 x 33.7 x 17.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17420-38100

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

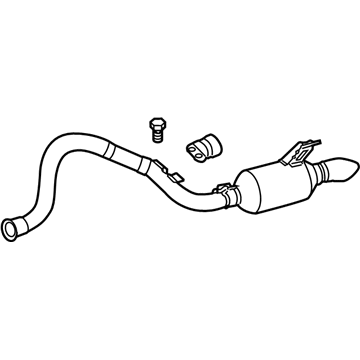

2008 Toyota Land Cruiser Tail Pipe

Part Number: 17430-38551$300.09 MSRP: $392.44You Save: $92.35 (24%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust Tail; Exhaust Pipe; Resonator; Muffler; Resonator & Pipe; Pipe Assembly, Exhaust, Tail

- Replaces: 17430-38550

- Part Name Code: 17430

- Item Weight: 11.00 Pounds

- Item Dimensions: 44.5 x 12.7 x 9.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17430-38551

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

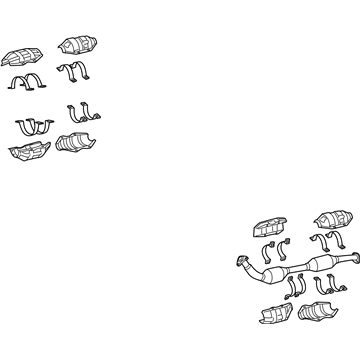

2008 Toyota Land Cruiser Pipe Assembly, Exhaust, Front, Driver Side

Part Number: 17450-38010$1763.10 MSRP: $2366.60You Save: $603.50 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust Front; Exhaust Pipe

- Position: Front Driver Side

- Part Name Code: 17450B

- Item Weight: 11.40 Pounds

- Item Dimensions: 42.4 x 14.6 x 9.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17450-38010

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

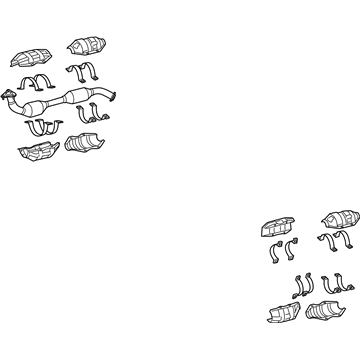

2008 Toyota Land Cruiser Pipe Assembly, Exhaust, Front

Part Number: 17410-38270$1744.71 MSRP: $2341.91You Save: $597.20 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe Assembly, Exhaust; Exhaust Pipe

- Position: Front

- Part Name Code: 17410

- Item Weight: 11.70 Pounds

- Item Dimensions: 48.6 x 18.6 x 9.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 17410-38270

- Warranty: This genuine part is guaranteed by Toyota's factory warranty.

2008 Toyota Land Cruiser Exhaust Pipe

Looking for affordable OEM 2008 Toyota Land Cruiser Exhaust Pipe? Explore our comprehensive catalogue of genuine 2008 Toyota Land Cruiser Exhaust Pipe. All our parts are covered by the manufacturer's warranty. Plus, our straightforward return policy and speedy delivery service ensure an unparalleled shopping experience. We look forward to your visit!

2008 Toyota Land Cruiser Exhaust Pipe Parts Q&A

- Q: How to install the exhaust pipe and its components on 2008 Toyota Land Cruiser?A: Installation of the exhaust pipe begins with the Air Fuel Ratio Sensor for Bank 1 Sensor 1 and continues with Bank 2 Sensor 1. The installation of exhaust pipe begins by first installing the No. 2 Heated Oxygen Sensor for Bank 1 Sensor 2 followed by installation of the Heated Oxygen Sensor for Bank 2 Sensor 2. The front exhaust pipe assembly installation requires new gaskets along with attachment of the front exhaust pipe to the exhaust manifold RH using three new nuts tightened to 54 Nm (554 kgf-cm, 40 ft-lbf). Organize the air fuel ratio sensor connector alongside the heated oxygen sensor connector before installing the cable clamp to the heated oxygen sensor wire harness. The installation of the front No. 2 exhaust pipe assembly requires a new gasket along with 3 new nuts to join the assembly to the exhaust manifold LH using a torques setting of 54 Nm (554 kgf-cm, 40 ft-lbf). After the attachment complete the connection of the air fuel ratio sensor connector and the heated oxygen sensor connector. The installation process of the center exhaust pipe assembly requires assistance from a vernier caliper to check the compression spring free length; replace the spring if its measurement falls below 43 mm (1.693 inches). After installing two new gaskets onto the front exhaust pipe and front No. 2 exhaust pipe, attach the center exhaust pipe to the 3 exhaust pipe supports for securing with 4 bolts and 2 compression springs that must be torqued to 43 Nm (438 kgf-cm, 32 ft-lbf) for the front exhaust pipe and 48 Nm (489 kgf-cm, 35 ft-lbf) for the front No. 2 exhaust pipe. Use 2 bolts to attach the exhaust pipe damper onto the tailpipe while torquing them to 19 Nm (194 kgf-cm, 14 ft-lbf). To finish the tailpipe assembly you must first attach the tailpipe to the 2 exhaust pipe supports while installing a new gasket onto the center exhaust pipe before connecting the tailpipe to this pipe and tightening the bolt using a new clamp at 32 Nm (326 kgf-cm, 24 ft-lbf) torque. Confirm the clamp has the right installation angle. Thorough exhaust gas leak checks must be conducted before installation of an under cover for the No. 2 engine.