×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Solara A/C Condenser

Air Conditioning Condenser- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 A/C Condensers found

Toyota Solara Condenser

Part Number: 88460-AZ003$115.40 MSRP: $161.70You Save: $46.30 (29%)Ships in 1-3 Business DaysToyota Solara Condenser

Part Number: 88460-06140$282.45 MSRP: $403.29You Save: $120.84 (30%)Ships in 1-3 Business DaysToyota Solara Condenser

Part Number: 88460-06050$314.32 MSRP: $448.77You Save: $134.45 (30%)Ships in 1-3 Business Days

Toyota Solara A/C Condenser

Choose genuine A/C Condenser that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM A/C Condenser for your Toyota Solara? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Solara parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

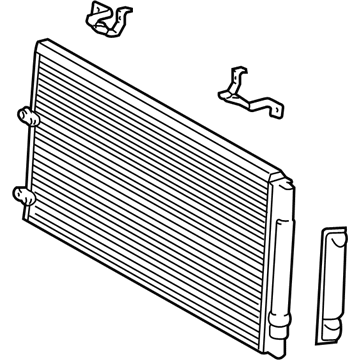

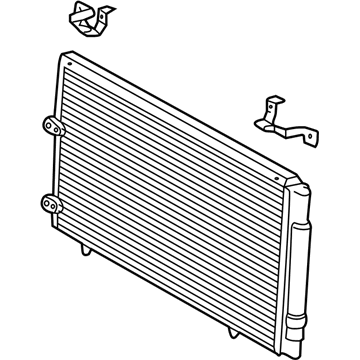

The A/C Condenser to Toyota Solara vehicles works mainly like a heat exchanger and is an integral part of the air conditioning system of the car. Its principle function is to cool the gaseous refrigerant and change it into a liquid state before it proceeds to the next phase of going to the accumulator. Usual types include the A/C Condenser; this is made of a number of tubes and is regularly mounted just behind the radiator for adequate air flow. Although such an overview does not record any distinctions of the types or styles of A/C Condensers fitted in the various Solara models, its constituent design is uniform across the series of models. The presence of the A/C Condenser is very crucial in providing the comfort of the cabin as well as the efficiency of the air conditioning system.

Toyota Solara A/C Condenser Parts and Q&A

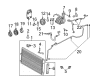

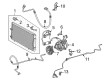

- Q: How to install an A/C Condenser on Toyota Solara?A:First install and torque bolted cooler condenser bracket No.2 to 4.4 Nm (45 kgf-cm, 39 in-lbf) while cooler condenser bracket No.1 should receive identical torque. The installer should use two nuts to attach the cooler condenser assembly at 9.8 Nm (100 kgf-cm, 85 in-lbf). When replacing a condenser the new unit should receive 40 cc (1.4 fl. oz.) of ND-8 or equivalent compressor oil. Install the radiator support upper component after confirming compatibility with the specified engine type between the 2AZ-FE or 3MZ-FE. To install cooler refrigerant pipe A, remove tape from sections, apply equivalent oil (ND-OIL 8) to new O-ring and joint, then attach the cooler and pipe with a bolt torqued to 5.4 Nm. The installation process must be completed twice on cooler refrigerant discharge hose No.1 while following steps to remove the vinyl tape, lubricate the hose joint with compressor oil, add a new O-ring to each joint and attach the hose to the cooler condenser assembly using a bolt tightened to 5.4 Nm (55 kgf-cm, 47 in-lbf). Complete the process by thoroughly charging the refrigerant system during engine heating then check for refrigerant leaks.

- Q: How to remove the A/C Condenser on Toyota Solara?A:The first step to remove the HVAC condenser is discharging refrigerant from the refrigeration system. The exclusion process starts by disconnecting cooler refrigerant discharge hose No.1 through bolt and O-ring removal followed by opening prevention with vinyl tape to block moisture and foreign matter entry. Detach cooler refrigerant liquid pipe A through the removal of its bolt and O-ring before using vinyl tape to seal the openings. The work process requires unmounting the air cleaner inlet assembly before moving on to the radiator support upper. The technician first removes cooler condenser bracket No.2 after its nut and then proceeds to take out cooler condenser bracket No.1 by removing its nut.