×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Scion Starter Motor

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Starter motors found

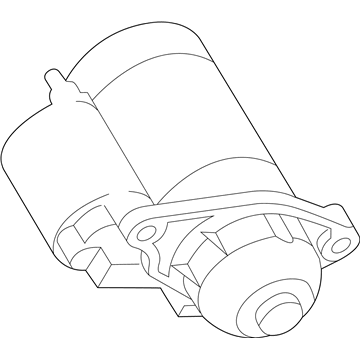

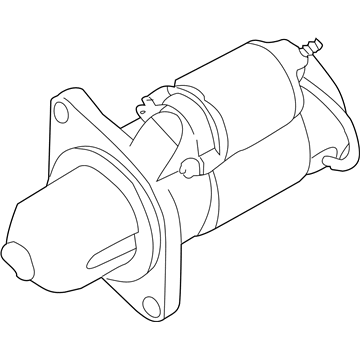

Scion Starter

Part Number: 28100-20020-84$156.25 MSRP: $219.85You Save: $63.60 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Starter Assembly; Starter Motor

- Replaces: 28100-20020

Scion Starter

Part Number: 28100-47151$239.86 MSRP: $342.47You Save: $102.61 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Starter Assembly; Starter Motor; Alternators

- Manufacturer Note: 12V 1.0KW

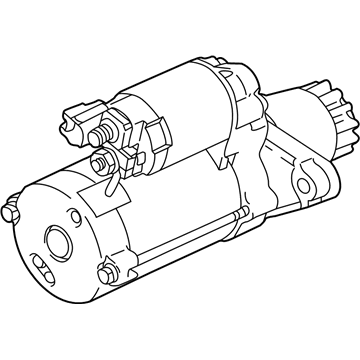

Scion Starter

Part Number: 28100-37041$237.18 MSRP: $338.64You Save: $101.46 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Starter Assembly; Starter Motor

- Manufacturer Note: 12V 1.6KW

- Replaces: 28100-37040

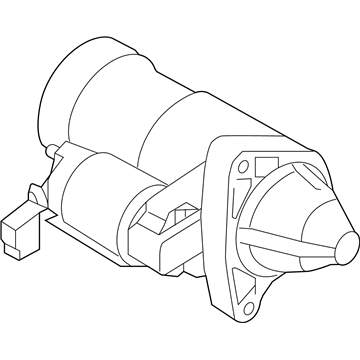

Scion Starter

Part Number: 28100-20022$247.32 MSRP: $353.11You Save: $105.79 (30%)Ships in 1 Business DayProduct Specifications- Other Name: Starter Assembly; Starter Motor

- Manufacturer Note: 12V 1.7KW

- Replaces: 28100-20021

Scion Starter

Part Number: 28100-21062-84$158.26 MSRP: $222.70You Save: $64.44 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Reman Starter; Starter Motor

- Replaces: 28100-21061, 28100-21062

Scion Starter

Part Number: 28100-28041-84$166.32 MSRP: $234.13You Save: $67.81 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Starter Assembly; Starter Motor

- Replaces: 28100-28040, 28100-28041

Scion Starter

Part Number: 28100-WB004$298.90 MSRP: $426.76You Save: $127.86 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Starter Assembly; Starter Motor

- Replaces: 28100-WB003, 28100-WB002, 28100-WB001

Scion Starter

Part Number: SU003-00451$365.25 MSRP: $497.82You Save: $132.57 (27%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Motor Ay-Starter; Starter Motor; Starter Assembly

- Manufacturer Note: 12V 1.0KW

Scion Starter

Part Number: SU003-00450$897.26 MSRP: $1222.90You Save: $325.64 (27%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Motor Ay-Starter; Starter Motor; Starter Assembly

- Manufacturer Note: 12V 1.6KW

Scion Starter

Part Number: 28100-37130$238.46 MSRP: $340.47You Save: $102.01 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Starter Assembly; Starter Motor

- Manufacturer Note: 12V 1.2KW

Scion Starter Assembly

Part Number: 28100-36120$247.20 MSRP: $352.95You Save: $105.75 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Starter Motor; Starter

- Manufacturer Note: 12V 1.7KW

- Product Specifications

- Other Name: Starter Assembly; Starter Motor; Alternators

- Manufacturer Note: 12V 1.6KW,COLD AREA SPEC(FOR NORTH AMERICA)

Scion Starter Motor

OEM parts deliver unmatched quality you can rely on. They pass extensive quality control inspections. Scion produces them to the official factory specifications. This process helps prevent defects and imperfections. So you can get exceptional lifespan and a flawless fit. Need new OEM Scion Starter Motor? You'll love our wide selection of genuine options. Shop in minutes and skip the hunt. Our prices are unbeatable, you'll save time and money. It's easy to shop and find the right piece. Our committed customer service team gives professional help from start to finish. Every part includes a manufacturer's warranty. We ship quickly, your parts will arrive fast at your door.

Scion Starter Motor makes the engine burst into life in seconds and transforms battery juice into sure movement each morning. In 2003, Scion came up in bold colors, no-frills pricing, and youth culture in its wink at the vehicle market. Scion sold very small Release Series editions that made the customer feel an in-group rather than a focus group. Scion continued the chatter by using virtual hangouts such as the branded city, which proved that a car brand could partake in online partying. Scion was also the idea lab of Toyota, attracting first-time drivers to purchase and selling more than 1,000,000 units before stepping out in 2016. Customers were fond of the hassle-free mono spec trim that gave them money to do their modifications and weekend outings. Reduced release paint programs transformed parking lots into traveling art galleries. Starter Motor converts battery electricity into a crisp rotational burst that secures a gear to the flywheel and cracks the engine within vicinities of a second and releases it out of the same vicinities under a second to avoid drag in running. Starter Motor is dependent on an outer solenoid that projects the pinion forward to engage positively on cold mornings or late evening departures. Starter Motor pack reduces gearing so that a small case can provide a laughable amount of torque that can withstand stop-and-go punishment. Starter Motor produces the usual rapid confident jerk of life with which the driver twists the key.

Scion Starter Motor Parts and Q&A

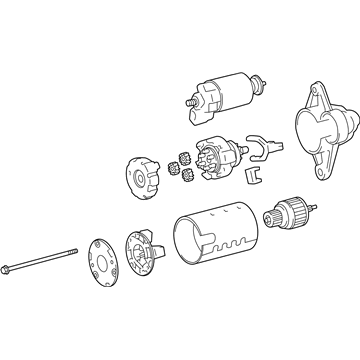

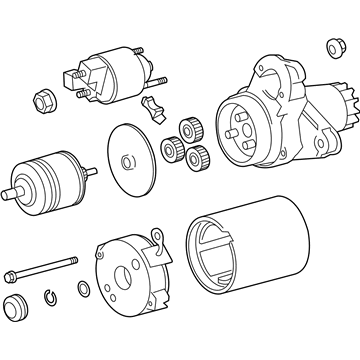

- Q: How to reassemble the starter motor on Scion tC?A:Start the starter motor assembly process by lubricating all pins on the planet shaft and planetary gears before sliding the three gears onto the planetary shaft pins. The startup process requires the starter armature assembly to receive grease on both the plate washer and armature shaft together with a new snap ring. You should employ snap ring pliers to properly install snap ring placement into the starter commutator end frame. Verify the snap ring length using a vernier caliper which should not exceed 5.0 mm (0.197 in.) otherwise replace it. Mount the starter commutator end frame cover into the beginning end of the starter commutator assembly frame. The implementation process begins by placing the starter commutator end frame rubber against the convex cutout of the starter yoke then installing it before positioning the starter armature plate keyway against the key inside the starter yoke and setting the plate. Apply lubricating grease to the starter armature gear followed by the proper alignment of the starter yoke key to the starter drive housing keyway and securely mount the starter commutator end frame with starter yoke into the starter drive housing using two bolts torqued to 6.0 Nm (60 kgf-cm, 53 in-lbf). When installing the starter magnetic switch assembly start by greasing the plunger and hook and inserting them into the starter drive housing before resting the starter magnetic switch into position using 2 screws torqued at 7.5 Nm (76 kgf-cm, 66 in-lbf). The lead wire needs connecting to the nut while torquing it to 10 Nm (100 kgf-cm, 7 ft-lbf).

- Q: How to remove and replace the starter motor on Scion xB?A:The removal process for 2AZ-FE starter motor begins with disconnecting the negative battery cable terminal. To begin the process remove the air cleaner cap sub-assembly through connector disconnection of the mass air flow meter followed by hose clamp loosening and then air cleaner assembly clamp unlocking before cap removal. The next task is to take out the air cleaner filter element sub-assembly from within the air cleaner case sub-assembly. The next step for air cleaner case sub-assembly removal consists of wire harness clamp separation and bolt uninstallation of three pieces. The starter assembly procedure for manual transaxle demands users to disconnect terminal 50 connector from the starter assembly then remove the nut connecting wire harness to terminal 30 and finally separate the 3 bolts to remove clutch flexible hose bracket and starter assembly. Automatic transaxle requires users to disconnect terminal 50 from the starter assembly before removing the wire harness nut at terminal 30 and removing the 2 bolts with the starter assembly.